So I just picked up a Mac Pro on the weekend. I tested it prior to purchase with the ASD S3132 diagnostic. It passed everything EXCEPT the TNOD test, where it gave an error that the IOH sensor was above operating temp. Knowing this i purchased the unit at a reduced rate in hopes of fixing it.

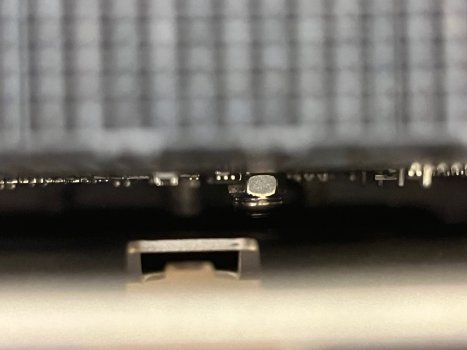

So researching this it seems the Northbridge heatsink and thermal sensor is not properly seated. There is a small plastic clip that is supposed to hold down the Northbridge heatsink that is gone, so it is not flush against the board.

this thread has a picture of the processor board stripped down, and the Northbridge missing the 2 clips that secure it to the processor board :

https://discussions.apple.com/thread/4501912?start=0&tstart=0

i think i'm only missing the one clip, as the processor heatsink is holding it down on one side already. Searching the web it seems that Apple does not sell just the clips, and the route most people are going seems to be to buy a whole new processor board. This seems like ridiculous overkill to me since the clip surely must be a 25 cent part. This thread has someone suggesting using glue to hold down the heatsink :

https://discussions.apple.com/thread/3099476?start=0&tstart=0

I'm not crazy about this solution, but may try it as a last resort.

I was thinking that a simple nut and bolt solution would work, but i'm not sure if using a metal part here could short something on the processor board. There might be a reason apple went with a plastic clip (although looking at my other 2009 mac pro processor board there does seem to be a spring mechanism on the clip, but i doubt this extends past the heatsink to make contact with the actual board....)

I could also try to find a plastic nut/bolt combination, but trying to find the right size may be more difficult because of the limited selection for plastic nuts & bolts.

Has anyone else run into this same problem? were you able to find a solution other than replacing the entire board?

Any other thoughts on a possible solution? I'm all ears...

So researching this it seems the Northbridge heatsink and thermal sensor is not properly seated. There is a small plastic clip that is supposed to hold down the Northbridge heatsink that is gone, so it is not flush against the board.

this thread has a picture of the processor board stripped down, and the Northbridge missing the 2 clips that secure it to the processor board :

https://discussions.apple.com/thread/4501912?start=0&tstart=0

i think i'm only missing the one clip, as the processor heatsink is holding it down on one side already. Searching the web it seems that Apple does not sell just the clips, and the route most people are going seems to be to buy a whole new processor board. This seems like ridiculous overkill to me since the clip surely must be a 25 cent part. This thread has someone suggesting using glue to hold down the heatsink :

https://discussions.apple.com/thread/3099476?start=0&tstart=0

I'm not crazy about this solution, but may try it as a last resort.

I was thinking that a simple nut and bolt solution would work, but i'm not sure if using a metal part here could short something on the processor board. There might be a reason apple went with a plastic clip (although looking at my other 2009 mac pro processor board there does seem to be a spring mechanism on the clip, but i doubt this extends past the heatsink to make contact with the actual board....)

I could also try to find a plastic nut/bolt combination, but trying to find the right size may be more difficult because of the limited selection for plastic nuts & bolts.

Has anyone else run into this same problem? were you able to find a solution other than replacing the entire board?

Any other thoughts on a possible solution? I'm all ears...

Last edited: