Got a tip for us?

Let us know

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

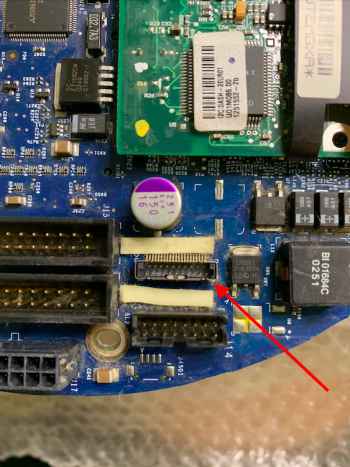

iMac G4 Board level repair

- Thread starter yakult121

- Start date

-

- Tags

- imac g4

- Sort by reaction score