Snow Tiger, sound like you know your trade! Thanks again for the info.

I went ahead and changed out my 6-Core CPU with a used 12-Core last night (took some time).

Glad I did it.

The thermal paste was

so dried out that it just flaked off with very minimal cleaning need. I had noticed higher temperatures with a few "free" apps over the past year (probably not accurate readings, but gives a general reading and

good enough for free apps), but nothing to cause a concern (I thought).

"If" I did not do this I would have a bag (or trash can)

of hurt soon...

During installation, there were a few "

hiccups" and issues...including a bolt on a bracket of the CPU un-attaching and had the talked about

black tamper proof stickers over the CPU screws (that ifixit does not show on their video) showed up..along with a few other minor challenges along the way...but overall, the process went well.

If someone is faint of heart to do this procedure...proceed with caution. I am ok with the challenges and took the risk, including enjoying the adventure...and it paid off indeed!

The Mac Pro 2013 is something to behold! I marveled at "

looking" at the inners while taking it apart (probably is why I took so long to do it...

Amazed

Amazed at the complexity, design and the logical thought behind it... Too bad Apple gave up on it.

I also decided to not do anything with the graphic cards right now to make sure there are no issues after so I would know

generally what or where if any issues came or come along..

I applied a "very thin" layer of Arctic MX-4 thermal compound and hope that it was enough. I was taught years back to "only" apply a very thin layer and that is all that is really "

suppose" to be applied if I can remember correctly. Not like "most" of the videos shown on youtube or articles I have read or seen recently... Every video I watched does the

opposite and cakes the thermal paste on.

Given that Arctic states on its package that the compound does not need replacing for at least 8 years, If I put too little on the CPU, I should at least be good for about 2 years (or a little more) and would reapply it again if needed. Again, I hope I am correct in my theory? I ONLY applied the thermal paste on the CPU and NOT the heat sink (as I was taught long ago to do). Hope I am correct...

Results: Currently, the Mac Pro 2013 is running VERY cool...watching the temperatures it is running 10c LOWER or more than before I did anything, its humming at 56c to 65c on basic or moderate tasks after measuring the CPU temperature with the free app "FANNY". Not sure how accurate it is..but the unit is DEFINITELY running cooler than before regardless.

Surprisingly, it looks like the GPUs are running cooler as well on normal tasks. I think after doing a good

dust cleaning while the unit was apart helped, the unit overall is running cooler to my delight.

I thought since the CPU's thermal paste was completely dry and flaky, it would be

obvious that the GPU thermal paste would also be dry since all the talk about the unit running hot GPUs and all of the other issues with the unit...but given the temperature readings and after dust cleaning the unit, the GPUs look like they are ok for now? idle time is in the 30c for the GPU and just normal or so use so far peaks around 47c. Looks like currently they are ok.

I have not tested it yet on a FCPX project, but guessing by the results currently, I should be also pleased with the results.

Conclusion:

I would have had to replace the thermal paste on the CPU REGARDLESS if I swopped out the CPUs or not...this concerns me...since the unit was purchased from Apple close to 4 years ago (and almost one year after extended Apple Care expiration).

If I did not do this...eventually I would start to have issues with my unit JUST after four years after directly buying from Apple...

My usage on the unit: I would say moderate video processing and editing (no 4K or over pushing on the unit) with the 6-Core, so I was surprised at the state of the thermal paste after just close to 4 years of use...

Again, I am soooOOOO glad I decided to take the risk and do this. Saved the unit, it is running fast and cooler, just like a new system (maybe better than when I got it).

To Snow Tiger: When and/or "If" I decide to do the procedure for the graphic cards, it sounds like you have a Tech shop or are a manufacturing plant etc. or other. Any way to order some of the material for the GPU thermal pads from you and cut the pads to shape myself? I have no idea where to get/order some of the material (looked around on the internet and came up empty). If not, do you know somewhere where I could buy the material and also what exactly should I ask for? Currently, I am working out of the U.S., so I would purchase and ship it to my residence in the states and pick it up when I visit (unless I can find it somewhere in my locations).

I would prefer not to get stuck if I take off the graphic cards and then notice also I need to replace the thermal pads (risk)... I can take this conversation offline if you would prefer and/or are able to help. No problem if you do not want to, You have already help greatly! Especially not having to tell my wife I have to buy another computer! Saved me from having to sleep on the couch for some nights

Glad there are still some knowledgable people on this forum that

honestly assist others!

[automerge]1589252360[/automerge]

Wera makes very nice tools .

My tactile feedback is sensitive enough and muscle memory from performing so many similar operations extensive enough , that I don't need to use torque drivers .

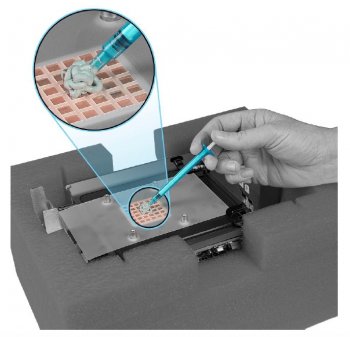

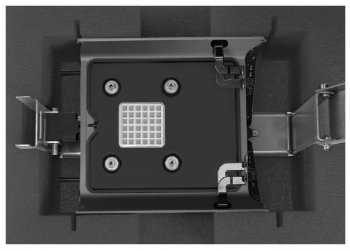

It is possible for DIYers to grab the official APN set of replacement GPU thermal pads for the MP6,1 , but they rarely need to be replaced unless damaged during component disassembly . At any rate , if I need to replace any gap TIM in a System I'll pull the materials from a hermetically sealed general inventory bin of gap materials . These materials are not specifically for any particular component , but are organized by size , etc . From large 300mm x 210mm sheets to 15mm x 15mm individual pads . They are further organized by thickness , shore hardness and thermal conductivity rating . Before application , I usually have to cut them with an x-acto knife to a very specific size . So , almost all thermal gap materials I use are custom made at time of need . It saves a lot of money as this stuff is more affordable in bulk and also helps to ensure product freshness .

In my shop , the general rule of thumb with Systems :

Traditional gap materials :

Voltage regulator gap TIM is 3M made with a TC rating of 1 W/m-k .

Vram and M.2 SSD gap TIM is Laird made with a TC rating of 3 to 4 W/m-K .

Overclocked or high performance components TIM are Fujipoly made with a TC rating of 7-17 W/m-k .

Experimental gap materials :

gap TIM is Panasonic soft PGS ( Pyrolytic Graphite Sheet ) with a TC rating of 20-28 W/m-k .

Just ask a company for a (small) sheet of this? The company should know what I am asking? But, not sure who to ask...sorry I'm an amateur.