I really like your solutions all.

Just to bring my take in, not realized though, just a thought.

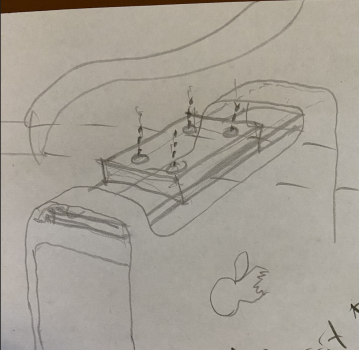

Two wooden planks approriately sized, glued together maybe. Four holes drilled through both. Attached to the table with screw lengts according to your desks dimensions (vertical height of the table top).

After installing with apropriate toleraces to the desktop., you can then just slide the rear (or the front) first in to it, end the slide a little bit back and tilt slightly, shove it in, and you are installed with it.

Of course there would be more to it to make it perfect, but I just thought this would be pretty quick, and dirty cheap too. You can make it yourself, or order through some carpentry shop. Well maybe not from a carpentry shop, probably from a Bauhaus or similar who do offer cut services for their stock wood products, straight from their shelves in a minute or two.

View attachment 2157883