yup , his business is not fixing macs , its youtube drama.I didn't watch the view but read the summary above. I have seen some of his videos and for me, he is too vulgar, melodramatic, and whiny. He creates his own drama and then accentuates with hyperbole for the YouTube camera.

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

Louis's M1 video

- Thread starter stevenaaus

- Start date

- Sort by reaction score

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Plus one for the Constant Geekery channel. An oasis of calm and reasoned analysis ?He indeed does that, his rants can be all over the place and as @leman said it sometimes feels like typical grooming, that is getting the user into an over-emotional (and thus irrational) state to weaken their defences, and that's how you lose your moral advantage over those you are accusing of the same thing.

That said, we can't really let it cloud our own judgement as a fact will remain a fact irregardless of what we feel of the messenger, polite lies are not worth more than a potentially rude truth.

On a side-note, the Constant Geekery channel is amazing in this regard, it's such a breath of fresh air listening to the guy.

Or you would have bought 5 year warranty for under $200 that would cover the repairs. And if your MacBook is over 5 years old? Then it is worth almost nothing and paying $300 to fix is is a waste of money. I mean, would you pay 10k to fix an old car that costs 20k?

The situation you describe is trivially avoidable by using basic financial discipline and planning. You just need to understand that laptops are tools that will depreciate and eventually break down. If you treat at them as a recurrent expense (e.g. $30 per month for a $1800 laptop that you want to keep for 5 years) instead of a one-time purchase and properly budget it, you will be fine.

That's a very harsh world you suggest we live in.

A bit like saying people in poor countries should not have children, and if they can't plan correctly should not get assistance.

Glad I don't like in a world such as you suggest

People who offer others help should be thanked, and appreciated, be that fixing a macbook cheaply or giving a starving person a free meal.

Saying "well you should have planned better" whilst it may be factually true, is not thankfully the world we live in.

Personally, I would not help someone like Louis who I find to be a hypocrite and offensive. He doesn't deserve to stay in business and gives the profession (and YouTube) a bad name (it wasn't great to begin with). Plenty of other electricians who could do this type of work.And yet you are totally against someone who would be able to do this type of work.

Personally, I would not help someone like Louis who I find to be a hypocrite and offensive. He doesn't deserve to stay in business and gives the profession (and YouTube) a bad name (it wasn't great to begin with). Plenty of other electricians who could do this type of work.

Again, let me just say, I'm no fan of him as a person, but I accept being in the UK myself an American from a certain area, who grew up in a certain way, may come over a little strong, and abrupt to me, so I don't really wish to pass judgement on the man, esp as he has worked hard and taken many financial risks, which I, and I'm sure most here have never taken to build his own successful business and youtube followers.

So, full respect to him from achieving that.

As I say, I don't feel any connection with him, as someone I would probably see as the type of quiet person I'd generally seek out to be friends with.

However, if I has a broken piece of equipment, and his store was local to me, and the price of a repair was good then I'd be happy to use his store.

He employs quite a few staff now who are obviously very highly skilled in what they do, and of course if people were not happy and I'm guessing recommended him to others, he would not have a business.

All personal viewpoints of any individual aside. I am (and I'm sure the vast majority of the population are also) very happy small, highly specialised and skilled repair shops, for all types of equipment exist.

And I will admit, top marks for him and others in the same field for being able to still offer this service, despite the best attempts of the GIANT companies doing everything they can think of to try and make him and others like him go out of business and not be able to offer members of the public a choice.

That's where we differ. I would not help him in any way, and instead I would help someone with better character as a human being. Shouldn't be too hard to find considering he's so low on the totem pole. When you help people like him you encourage their behavior.However, if I has a broken piece of equipment, and his store was local to me, and the price of a repair was good then I'd be happy to use his store.

That's a very harsh world you suggest we live in.

A bit like saying people in poor countries should not have children, and if they can't plan correctly should not get assistance.

Glad I don't like in a world such as you suggest

Completely the opposite! If you permit me this analogy, you are talking about a world where poor people have to rely on kindness of strangers to have health coverage, while I am talking about mandatory health coverage for all. Cheap insurance trumps paying $$$ to fix an outdated computer, always. If you are so keen of protecting people who cannot afford expensive computer repairs, you should be advocating for cheap long-term warranty rather than out-of warranty repairs.

And of course financial planning is important. If you can't reasonably afford to buy an expensive computer, why would you get one? To continue your example, if you are so poor that you can't feed your kids, is it really the best idea to buy a $2000 laptop, not to mention spending $300 to fix something that has very little value and could give out any moment?

People who offer others help should be thanked, and appreciated, be that fixing a macbook cheaply or giving a starving person a free meal. Saying "well you should have planned better" whilst it may be factually true, is not thankfully the world we live in.

Rossmann is not "helping others", he is running a for-profit business. One could reverse your argument and say that he is taking advantage of people with poor financial planning.

However, if I has a broken piece of equipment, and his store was local to me, and the price of a repair was good then I'd be happy to use his store.

I fully agree. But the key here is "price of repair was good". You are taking about spending $300 to repair a device that costs $300-500 on eBay. That is not a good price — no matter how you swing it, because not only do old computers depreciate in value very quickly, but they also get progressively more prone to failures with age. In fact, it might be cheaper long-term to take a loan and buy a new one.

Can you give some link about that? Or how to do it?bought 5 year warranty for under $200

Can you give some link about that? Or how to do it?

You need to search for options locally available to you, most retailers have will have an offer. My local parter in Switzerland offers a really nice device subscription service where you pay monthly and can always switch devices to a newest one (kind of like a lease, but better conditions), which is perfect for someone like me who likes to buy a new laptop every two years.

For the USA, I found this offer, no idea who this company is or how they would compare to extensions offered by retailes: https://securranty.com/Apple-MacBook-Insurance Anyway, the price seems reasonable (about 10% of the average device price for the 5-year plan). For a 13" MBP it's $140. Fun observation: the same coverage for a non-Apple laptop of comparable price is $200, which means that the insurance provider is very confident that the MacBooks have lower failure rates.

Really? Yet people here seem to forget that Apple employees (including Tim Cook) are also "Members of the Public" yet both TC and Apple employees are trashed here daily.That's a very odd point of view, and pretty negative towards normal members of the public which makes me sad.

Firstly, don't make up crap scenarios. And it's very strange that you're evangelizing LR and defending him so much. You're making up a Coulda Woulda Shoulda nonsense scenario. And I've been a Mac user exclusively for nearly 30 years and I've had no issues with Apple fixing my equipment. I would never take my Macs to an UNAUTHORIZED repair place such as LR. He's is NOT an Apple Certified Repair service, so stop the nonsense scenarios please.Imagine if you were struggling for money as a parent, working from home perhaps, and your macbook had a fault.

Apple refused to fix a component as they don't do that type of repair and quoted you perhaps $1000 for a totally new board swap, which would take 2 weeks.

Or you found Louis who was able to spot the problem, let's say a burned out capacitor and damaged resistor and would charge you $300 and be ready in 4 days.

You're doing too much promotion and defending of LR, and please don't pretend that you care about my financial well being.That could be a giant difference for you and your family and your income/job.

I'm against idiots like him who trash companies to achieve clicks on YouTube along with getting underserved business for repairing Apple's computers.And yet you are totally against someone who would be able to do this type of work.

LR isn't helping anyone but himself. Are you for real? Wow a lot of apologizing for him. SMH.It's sad you are so negative towards people who are able to help others out

Really then you've haven't been on MR for very long have you? The sheer amount of Apple trashing towards individuals who make a living at Apple is deplorable. Louis Rossman is a large POS and snake oil salesman.

In fact let me say it again:

I find it incredibly sad that any individual would be so nasty to another person who is able to mend a broken product owned by another human being in the quickest and cheapest way possible.

You judging me is out of line here. You taking my opinion personally seems very bizarre. Do you work for LR? Sure sounds like it.What a horrid world we would be in, if everyone felt and acted in this way

Louis Rossman deserves no respect. You've got way too much defending going on for someone who makes his living trashing Apple and coercing people to get their Macs repaired from an NON-AUTHORIZED services such as him.

So so sad we have people here that hold this viewpoint, and wanted people who were able to help others to no exist/go away

Tell that to someone who's deaf and blind. They may believe it.

As a final follow up, my views above have zero to do with me liking or not liking Louis as a person or his personality.

?

Tell that to someone who's deaf and blind. They may believe it.

?

Anyway, no worries at all.

We thankfully live in a world where people who purchase equipment are still free to take it to various places to have it repaired.

Some companies have and still are trying to stop this, but they won't win in the end, as freedom for the consumer will always win out against big business.

You, and others will always wish to take your products to the original company to be repaired.

Others will be happy to use other people to obtain service.

Just like with cars, and all electrical goods we buy them, we own them, and are free to do as we like with them.

It's good that we live in such a world.

Trust me. If there was ever a law that said, every single product you ever purchase in your entire life, could only, by law be repaired, only by the same company that made that product, almost everyone would vote against it, and I dare say you would not even wish such a law to be passed.

It's good we live in a mostly free world, and pray we always will.

You do what you want to do. Nowhere in any of my posts said that you couldn't do it. You attacked my opinion on that POS snake oil salesman called Louis Rossman, remember?Anyway, no worries at all.

We thankfully live in a world where people who purchase equipment are still free to take it to various places to have it repaired.

And it makes much more sense to a lot more people to do that. Why it bothers you at all that many of us don't care for LR and don't care to take our Apple equipment to unauthorized repair places is beneath me.You, and others will always wish to take your products to the original company to be repaired.

Others? I don't see anyone here agreeing with you about how "valuable" it is to give business to repair places that aren't even authorized to repair Apple equipment. Do what you want, it's your money, but don't come here trying to "straighten people out" as if we are wrong in our opinion about Rossman.Others will be happy to use other people to obtain service.

Once again, I never said you couldn't do what YOU want to do with YOUR equipment but you seem to think you have a right to tell the rest of us where to take our Macs (Louis Rossman) as if you're saving us. ?Just like with cars, and all electrical goods we buy them, we own them, and are free to do as we like with them.

It's good that we live in such a world.

Uh no. That would be my first mistake.Trust me.

And I never stated that a Mac should only be repaired by Apple, but I will get my Macs repaired by Apple or an Apple authorized service center. I would never trust my money and my Macs with an ****** who makes his living making Apple-trashing videos with attempts to make people feel stupid if they don't get their Apple repairs done by him. A snake oil salesman at best.If there was ever a law that said, every single product you ever purchase in your entire life, could only, by law be repaired, only by the same company that made that product, almost everyone would vote against it, and I dare say you would not even wish such a law to be passed.

You should repeat that over and over to yourself because you've done nothing but try and tell the rest of us here who don't trust that snake oil salesman Louis Rossman that we are wrong and we should trust him with our repairs and trust his judgement. SMH.It's good we live in a mostly free world, and pray we always will.

Last edited by a moderator:

What's comical is you're attacking anyone's post here who doesn't trust Louis Rossman with a 10 foot pole because of how he makes his living trashing Apple yet you don't have a single Apple MacBook in that plethora of tech products listed in your signature. Doesn't surprise me one bit...That's a very odd point of view, and pretty negative towards normal members of the public which makes me sad.

So, not any deal from Apple, just very questionable local sites and with "i sended laptop and there's no return" reviews. Seems like a very bad recomendation. Lets just think that current Apple laptops now good only for three years usage on AppleCare and reselling after (not only them of course, but still).You need to search for options locally available to you, most retailers have will have an offer. My local parter in Switzerland offers a really nice device subscription service where you pay monthly and can always switch devices to a newest one (kind of like a lease, but better conditions), which is perfect for someone like me who likes to buy a new laptop every two years.

For the USA, I found this offer, no idea who this company is or how they would compare to extensions offered by retailes: https://securranty.com/Apple-MacBook-Insurance Anyway, the price seems reasonable (about 10% of the average device price for the 5-year plan). For a 13" MBP it's $140. Fun observation: the same coverage for a non-Apple laptop of comparable price is $200, which means that the insurance provider is very confident that the MacBooks have lower failure rates.

I'm not a huge fan of Louis's attitude, but the issue I have is with Right to Repair, not Louis. If he helps further the whole Right to Repair, then he can complain all he wants. Apple has lots of quirks and defects, but Dell, HP, Lenovo, etc all have their own faults. That being said, Apple really screwed up with the iPhone 6/6 Plus design. Why did they put underfill on all ICs except the touch controller? Why did they then relocate the touch controller to the display on the 6S/6S Plus? If it was such a great design choice, why change it? If the aluminum was strong in the 6/6 Plus why did they change the aluminum alloy to a stronger aluminum in the 6S/6S Plus version?

Another example that I didn't know about until I recently when I was working on one, is that the display connector layout changed in the 2016 Touch Bar machines. From at least 2006 until the Touch Bar models Apple used a LVDS connector and the pinout kept the display data lines separated from the 40-50V backlight lines with several traces connecting to ground. Should a short occur from liquid damage or humidity cause corrosion, the backlight voltage would short to ground and blow the fuse on the board. Well with the newer Touch Bar machines, this press on connector has a 50V backlight line right next to a data line. Humidity can cause slight corrosion which becomes conductive. Those data lines are fragile, and putting backlight voltage on them damages the MUX IC on discrete graphics machines or damages the CPU on the 13" models. You would easily damage USB equipment if you applied 5V to the data lines instead of keeping that voltage on the power lines.

Again, I think he's overly critical on numerous things, but I do hope for a day where people have a right to repair their own machines. I have the service manual, exploded view, wiring layout (w/ pinouts), engine diagnostics and rebuilding specifications for my Mazda RX-8 and an old W220 S500. I've got a board layout, schematic, BOM and service guide for my audio gear, some as old as 1978, some as new as 2009.

I was recently working on a HomePod that made a random popping noise. I determined the problem to be the with the Class D amplifier IC that was putting out DC offset and literally cooking the voice coil of the woofer. It's part 98-0431, by International Rectifier (now owned by Infineon) Pin out wise it's similar to the PowlRaudio ICs for sale from Mouser/DigiKey, but not identical. Contacting Infineon got me this response

Keep in mind Apple doesn't repair your product. They replace it or replace the defective part/assembly in the product. Apple doesn't troubleshoot devices like AirPods or HomePods (see above video) Heck I doubt Apple's Genius technicians know what "DC offset" even means.? They ship the device or defective/broken part/assembly to China where children working in a sweatshop do board rework. Sometimes those kids don't do a good job. I had a replacement MBP logic board for my own computer come to the shop with a damaged keyboard connector. Had to mark that board as DOA and they resent another. Now they get to send the poorly reworked board and the original defective board back to China to be corrected. I've also seen replacement boards come with scratches, poorly soldered components and liquid damage. Do you want your defective board to be replaced with a refurbished but previously liquid damaged logic board?? We also had a problem for a while where the top cases for the white unibody MacBook A1342 weren't glued properly. The top plastic area above they keyboard wasn't glued to the metal internal frame. We notified Apple, but nothing was done for a few months. In the end we super glued 50-70 of those top cases before proceeding with repairs.

I find it concerning that they are soldering the storage to the logic board rather than use a socket like they previously did. Soldering the ram was okay with me since I often have to re-seat ram in people's laptops (MacBooks included) when they get knocked over, but soldering my data to the logic board is excessive and is a great example of form over function considering SSD's can easily wear out before anything else does.

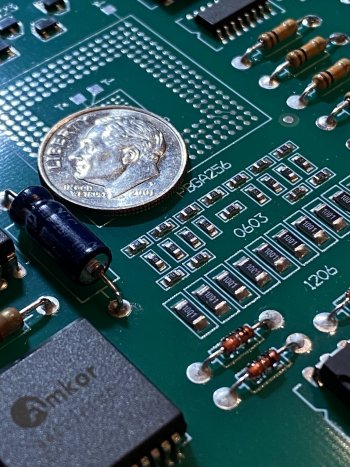

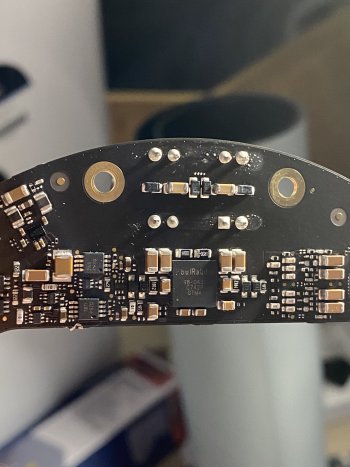

I take it most of the people here have never used screw driver, multi meter or even a soldering iron, and would rather pay Apple to swap components for them, and that's okay, it's your money. Some of us want the ability to work on our equipment. I work 40 hours a week soldering components to PCBs under a microscope so I'm familiar with what Louis actually does. Can any of you solder these? Don't worry, they get much smaller than those 0603 resistors on the first photo.

Another example that I didn't know about until I recently when I was working on one, is that the display connector layout changed in the 2016 Touch Bar machines. From at least 2006 until the Touch Bar models Apple used a LVDS connector and the pinout kept the display data lines separated from the 40-50V backlight lines with several traces connecting to ground. Should a short occur from liquid damage or humidity cause corrosion, the backlight voltage would short to ground and blow the fuse on the board. Well with the newer Touch Bar machines, this press on connector has a 50V backlight line right next to a data line. Humidity can cause slight corrosion which becomes conductive. Those data lines are fragile, and putting backlight voltage on them damages the MUX IC on discrete graphics machines or damages the CPU on the 13" models. You would easily damage USB equipment if you applied 5V to the data lines instead of keeping that voltage on the power lines.

Again, I think he's overly critical on numerous things, but I do hope for a day where people have a right to repair their own machines. I have the service manual, exploded view, wiring layout (w/ pinouts), engine diagnostics and rebuilding specifications for my Mazda RX-8 and an old W220 S500. I've got a board layout, schematic, BOM and service guide for my audio gear, some as old as 1978, some as new as 2009.

I was recently working on a HomePod that made a random popping noise. I determined the problem to be the with the Class D amplifier IC that was putting out DC offset and literally cooking the voice coil of the woofer. It's part 98-0431, by International Rectifier (now owned by Infineon) Pin out wise it's similar to the PowlRaudio ICs for sale from Mouser/DigiKey, but not identical. Contacting Infineon got me this response

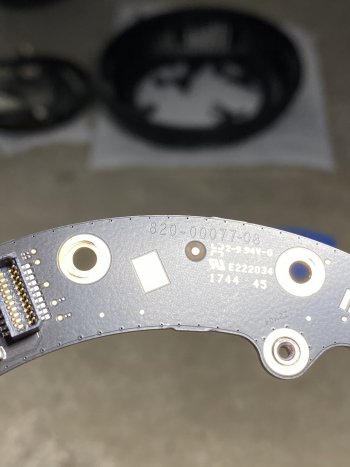

It's no more than an $8 part, and obviously no "Genius" or Apple rep knows **** about it because it's something that only the engineers would be familiar with. The amp board's Apple part number is 820-00077-08, but there's no schematic available, so one can't easily diagnose any other issues. Of course Apple isn't going to sell part 820-00077-08 to the public, and if they did, they'd probably charge $250 when you could buy a whole new HomePod for $299Hello Nick,

Please note that the part number 98-0431 is not a standard Infineon/IR part number. This is actually a custom part which was manufactured for an OEM. Please contact the manufacturer of the equipment being repaired for more information on this part or for a recommended replacement.

Best regards,

Infineon Technologies

Keep in mind Apple doesn't repair your product. They replace it or replace the defective part/assembly in the product. Apple doesn't troubleshoot devices like AirPods or HomePods (see above video) Heck I doubt Apple's Genius technicians know what "DC offset" even means.? They ship the device or defective/broken part/assembly to China where children working in a sweatshop do board rework. Sometimes those kids don't do a good job. I had a replacement MBP logic board for my own computer come to the shop with a damaged keyboard connector. Had to mark that board as DOA and they resent another. Now they get to send the poorly reworked board and the original defective board back to China to be corrected. I've also seen replacement boards come with scratches, poorly soldered components and liquid damage. Do you want your defective board to be replaced with a refurbished but previously liquid damaged logic board?? We also had a problem for a while where the top cases for the white unibody MacBook A1342 weren't glued properly. The top plastic area above they keyboard wasn't glued to the metal internal frame. We notified Apple, but nothing was done for a few months. In the end we super glued 50-70 of those top cases before proceeding with repairs.

I find it concerning that they are soldering the storage to the logic board rather than use a socket like they previously did. Soldering the ram was okay with me since I often have to re-seat ram in people's laptops (MacBooks included) when they get knocked over, but soldering my data to the logic board is excessive and is a great example of form over function considering SSD's can easily wear out before anything else does.

I take it most of the people here have never used screw driver, multi meter or even a soldering iron, and would rather pay Apple to swap components for them, and that's okay, it's your money. Some of us want the ability to work on our equipment. I work 40 hours a week soldering components to PCBs under a microscope so I'm familiar with what Louis actually does. Can any of you solder these? Don't worry, they get much smaller than those 0603 resistors on the first photo.

Attachments

Last edited:

Two more examples. A teacher contacted me a few years ago because their son's A1342 MacBook's battery swelled up cracking the trackpad and pushing it out. Apple quoted them $450 for OOW repair because the so called Genius said it might need more than a trackpad and battery (it would be shipped to a a repair depot in Texas) $440 for a computer that was 6-7 years old at the time is crazy. Probably would have ended up in the landfill if they didn't text me. I have several A1342 donor MacBooks and installed a used but working trackpad and used low cycle count battery all for $130. You can't go to an Apple Store to order a replacement trackpad or a replacement battery. Apple doesn't sell replacement parts.

Another example from last year involved my Mid 2014 Retina MBP 13". It needed a new battery so I brought it to the Apple Store expecting to pay the $199 battery fee. It was telling me to "Service Battery Now" and lasted an hour. The Genius ran MRI (Mac Resource Inspector) and everything but the battery passed (no surprise) They sent it to CSAT in Texas (that's the repair depot they use because they pay the employees poorly.. its basically an American sweatshop, look it up) and I get a email from Apple saying it won't be repaired because they found out my iSight camera is defective. I told them that it was working before I sent it and it passed the tests at the store. I use it to have a Group FaceTime call with my aunt and brother weekly, so it was recently working. They didn't care and quoted me $449 for a display assembly. I told them just to fix the battery, but they will not send back a partially working machine. So suddenly the $199 battery fee doesn't apply to me.

Imagine going to a dealership for some suspension work and they won't replace your struts on your car because the reverse view camera went out..

It get's better, I tell them to send it back unprepared as I was going to throw it on eBay as is and get another 2014-2015 non butterfly machine with MagSafe. They sent it back with a new top case and NEW BATTERY with 0 cycles. I bring it up to the Genius and he's obviously an idiot because he told me that my model was covered under the butterfly keyboard extension program (I told him it's a 2014, and he said it must be covered under something then)

I could have raised hell because someone damaged the camera on my 6 year old MacBook Pro, but I'll just use my iPhone and iPad for FaceTime calls and stick with a new battery for $0.00! Imagine if they didn't glue the battery in place and sold the battery to customers like me. I've seen new Dells that are just as thin as my 2014 MBP and the battery is screwed in place. I can call my car dealership, appliance repair shop, etc, give them a part number, get a price and buy it if I want to

Another example from last year involved my Mid 2014 Retina MBP 13". It needed a new battery so I brought it to the Apple Store expecting to pay the $199 battery fee. It was telling me to "Service Battery Now" and lasted an hour. The Genius ran MRI (Mac Resource Inspector) and everything but the battery passed (no surprise) They sent it to CSAT in Texas (that's the repair depot they use because they pay the employees poorly.. its basically an American sweatshop, look it up) and I get a email from Apple saying it won't be repaired because they found out my iSight camera is defective. I told them that it was working before I sent it and it passed the tests at the store. I use it to have a Group FaceTime call with my aunt and brother weekly, so it was recently working. They didn't care and quoted me $449 for a display assembly. I told them just to fix the battery, but they will not send back a partially working machine. So suddenly the $199 battery fee doesn't apply to me.

Imagine going to a dealership for some suspension work and they won't replace your struts on your car because the reverse view camera went out..

It get's better, I tell them to send it back unprepared as I was going to throw it on eBay as is and get another 2014-2015 non butterfly machine with MagSafe. They sent it back with a new top case and NEW BATTERY with 0 cycles. I bring it up to the Genius and he's obviously an idiot because he told me that my model was covered under the butterfly keyboard extension program (I told him it's a 2014, and he said it must be covered under something then)

I could have raised hell because someone damaged the camera on my 6 year old MacBook Pro, but I'll just use my iPhone and iPad for FaceTime calls and stick with a new battery for $0.00! Imagine if they didn't glue the battery in place and sold the battery to customers like me. I've seen new Dells that are just as thin as my 2014 MBP and the battery is screwed in place. I can call my car dealership, appliance repair shop, etc, give them a part number, get a price and buy it if I want to

So, not any deal from Apple, just very questionable local sites and with "i sended laptop and there's no return" reviews. Seems like a very bad recomendation. Lets just think that current Apple laptops now good only for three years usage on AppleCare and reselling after (not only them of course, but still).

I don't know the company and it very well might be not the best option. It was just the first hit on my google search. Again, you need to look what is available to you locally. It would be great if Apple offered a reasonably priced warranty extension, but alas, they do not.

And then again, I might be just too naive to how insurances or warranty extensions work in the USA. It is possible that I am spoiled by the "socialist" Europe where you generally get good customer service and insurances are cheap and abundant.

I think it's the hyprocrisy of Apple that gauls Louis, me and others. Sure, if you want to make a buck obsoleteing hardware ... that's your business model. They're a hardware company first. But pretending to be in any way green, laugh - they're as green as British Petroleum - and the measures they go through to extinguish totally *useful* and *legit* non-apple repair businesses, is just amazing.

I can't watch this guys videos, he makes me cringe.

Same here. I like his technical videos where he describes how he diagnoses/fixes problems but the guy is just such a baby that does nothing but bitch and moan about Apple. Then again, I guess hating on Apple is a good way to get clicks on YouTube.

Man, I’m paying 10k to fix an old truck that I bought for $200. I can totally understand wanting to keep anything going, no matter the vintage.I mean, would you pay 10k to fix an old car that costs 20k?

Farmers I know still use tractors from the 30’s, because they still work and can be repaired easily.

I would if I was restoring a collectors car. Most of that is in labor and not parts anyway, which is why I work on my own cars and Macs.I mean, would you pay 10k to fix an old car that costs 20k?

Man, I’m paying 10k to fix an old truck that I bought for $200. I can totally understand wanting to keep anything going, no matter the vintage.

Farmers I know still use tractors from the 30’s, because they still work and can be repaired easily.

I certainly know what you are talking about. I own a food processor that was originally designed in the 1940-ties and sold since then with only minor modifications. That thing is as robust and reliable as it gets and if it every breaks down I am definitely going to repair it. Same goes for my tower speakers. But again, a computer is not a tractor. Your truck seems to have real value (inherent repairability, reliability, possibly rarity), and an old tractor can be a superior tool under circumstances... but we are talking about laptops here. An old car can have it's important parts completely rebuilt and be better than new. You can't do this with a laptop, unless you put new components into the old chassis. It's just a different kind of wear and tear, as well as different kind of utility depreciation...

Register on MacRumors! This sidebar will go away, and you'll see fewer ads.