[QUOTE = "kinchee87, publicación: 28421112, miembro: 95006"]

Este ha sido un viaje de ingeniería increíble que no habría sucedido si [USER = 1213089] @Jordi Padreny [/ USER] no quitó el disipador de calor de su MacBook Air. Aquellos que posteriormente hicieron el mod de disipador de calor también me dieron algo de confianza para probarlo también:RE

Voy a editar mis fotos del disipador de calor ahora, ¡así que espero que pronto obtengan algunas mediciones aproximadas!

[/CITAR]

[automerge]1588275376[/automerge]

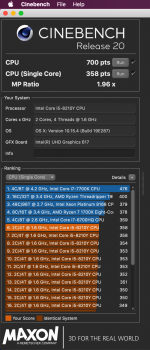

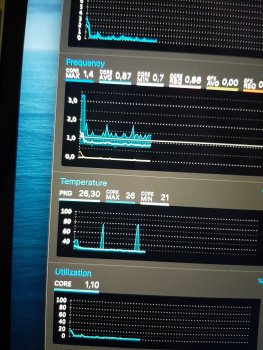

Thankful you acknowledge my audacity with a 2019 MBA purchased only two weeks ago, to achieve superior performance with home-made materials by virus confinement.

Any questions about the wind tunnel by private.

Greetings from Barcelona !!!

Este ha sido un viaje de ingeniería increíble que no habría sucedido si [USER = 1213089] @Jordi Padreny [/ USER] no quitó el disipador de calor de su MacBook Air. Aquellos que posteriormente hicieron el mod de disipador de calor también me dieron algo de confianza para probarlo también:RE

Voy a editar mis fotos del disipador de calor ahora, ¡así que espero que pronto obtengan algunas mediciones aproximadas!

[/CITAR]

[automerge]1588275376[/automerge]

Thankful you acknowledge my audacity with a 2019 MBA purchased only two weeks ago, to achieve superior performance with home-made materials by virus confinement.

Any questions about the wind tunnel by private.

Greetings from Barcelona !!!