Nah, I bet you it's supply chain constrains and optimizations.

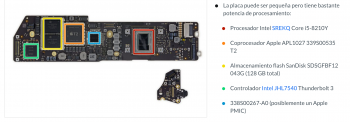

Actually I think I'm wrong - looking back through the thread, the 2018, 2019 and 2020 i3 MBA's all have aluminium heat sinks, whereas the 2020 i5s and i7s that have been posted have copper. There goes that hypothesis.

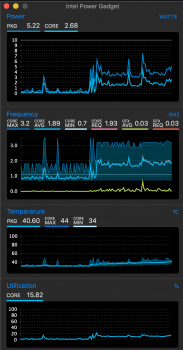

New hypothesis: the quad core 2020 MBAs have copper heat sinks and Apple's testing judged this to be an acceptable adaptation to the higher TDP of the i5/i7. Across all three models released in 2020, they still seem to have gone with the semi-solid, graphite-based thermal paste to contact the CPU/GPU die to the heat sink, despite the gap between the two.

Seems like this is a perfectly fine cooling solution for the dual core, but varies with the i5/i7. We've had users with the same apps/workload/OS report wildly different temperature/fan data on their i5s and i7s.

So to keep it real simple -

1. All three CPU options in the 2020 MBA are hard coded to particular performance limits by Intel/Apple.

2. It is possible to nudge this limit slightly upwards by modifying the thermal conductivity of the heat sink, but the main benefits are in cooling and fan noise.

So the flow chart goes:

Do you have a 2020 Macbook Air?

If

yes, are you happy with how it performs, its noise level and its internal and external heat management?

If

yes, awesome!

If

no, you can:

a) return and hope for a better heat sink with your replacement,

b) return for a base model MBP if your main issue is with sustained performance which the MBA cannot match, even with the most extreme modifications, or

c) perform a simple modification with a copper shim and thermal paste which should fix internal and external heat management.