Regarding the drives an 800K and two 2Mb where i suspected broken heads, the real fact differently where an interrupted capacitor behind the flat connector in the 51W, a blocked stepper motor and yes only in one drive a broken heads where someone probably moving badly the flat in and out crack it. (repair it is possible.. but i leave it there.. ^_^)

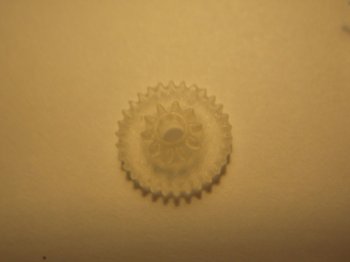

For the 400K someone asked me the little gear as replacement and that produced to solve the eject motor problem; i post here the pictures of 3 gear i produce yesterday for a guy to repair their drive; if someone want these gears i can produce them with the system i used (not 3D printing as by the guy inspired by the post).. to me are good, hard, strong and after some period of test also durable ; PM me if you need these gears.

; PM me if you need these gears.

To me both drive SONY 400K,800K or 2Mb have electronic and mechanism fully reparable; i tried to work a tests for the alignment also over 3 drive 800K; it took me some time playing with the align sensor and the step motor but all goes well with the perfect reading of the track zero.

For the 400K someone asked me the little gear as replacement and that produced to solve the eject motor problem; i post here the pictures of 3 gear i produce yesterday for a guy to repair their drive; if someone want these gears i can produce them with the system i used (not 3D printing as by the guy inspired by the post).. to me are good, hard, strong and after some period of test also durable

To me both drive SONY 400K,800K or 2Mb have electronic and mechanism fully reparable; i tried to work a tests for the alignment also over 3 drive 800K; it took me some time playing with the align sensor and the step motor but all goes well with the perfect reading of the track zero.

Attachments

Last edited: