The amount of time, money and energy that it would take makes it not worth it. I rather take the hit and move on, I'm trying not to be negative (my first thought after I found out he duped me was to go over to his place and "have a talk") and learn from this experience.Perhaps you can file a small claims court action against him? I know it's not the ideal option however he may be willing to work with you in order to avoid such an action.

Got a tip for us?

Let us know

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

Mac Pro 4,1 Firmware flashed to 5,1 issue

- Thread starter databaze

- Start date

- Sort by reaction score

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Apple Store will definitely not install any aftermarket CPUs into a Mac Pro. You may be able to find a service provider who does it, but you'll likely end up needing to do the work yourself.

Yeah, I know, that's a rhetorical question to SteveJobzniak. He suggested that Apple installed a flashed CPU tray in my 4,1.

I ended up having to take someone to small claims and I found it to be fairly easy. Small filing fee (think it was $15) and we didn't even appear in court as they attempt to arbitrate cases prior to court. The defendant and I reach a mutual agreement and I was able to recover part of my damages.The amount of time, money and energy that it would take makes it not worth it. I rather take the hit and move on, I'm trying not to be negative (my first thought after I found out he duped me was to go over to his place and "have a talk") and learn from this experience.

However if you feel the effort isn't worth it I completely understand. Sometimes that is the best option.

Yeah, I know, that's a rhetorical question to SteveJobzniak. He suggested that Apple installed a flashed CPU tray in my 4,1.

Wait, then if i get the new board i can use the 3.46Ghz cpus to boot up and flash it?

Wait, then if i get the new board i can use the 3.46Ghz cpus to boot up and flash it?

I don't know where the flashed component is. If it's on the logic board, then replacing the CPU tray won't matter. You'll still have the flashed logic board. If it's on the CPU tray, then yes, you'll have to flash it again to work with the newer CPUs.

If the latter case is true, PM your address and I'll loan you a W3530 so you don't have to buy an old CPU just to flash it.

Thanks for the offer, I just got two E5520 for $3.5 on ebay, but it was a silly buy since I found out that the backplane is the one that gets flashed not the CPU board, I just needed to get a new processor board, I'm trying to decide where to buy it, there are none on ebay and not sure which online stores are actually good, there is this place called macpalace that sales it at 375 against the 550 of dvwarehouse....any recommendations?I don't know where the flashed component is. If it's on the logic board, then replacing the CPU tray won't matter. You'll still have the flashed logic board. If it's on the CPU tray, then yes, you'll have to flash it again to work with the newer CPUs.

If the latter case is true, PM your address and I'll loan you a W3530 so you don't have to buy an old CPU just to flash it.

Wait, then if i get the new board i can use the 3.46Ghz cpus to boot up and flash it?

You can boot your Mac with the new CPU tray and no need to flash it again.

So, it seems the firmware is stored in the logic board, but not the CPU tray.

Good point, the firmware is probably stored on the logic board. The CPU tray is just a riser for the logic board.

And yes, people who install 6-core CPUs in unflashed machines cannot boot and have to take their machines to Apple to rescue them (by installing older CPUs, then flashing, then installing the 6-cores). Plenty of people had to do that in the netkas thread. One poor guy had no Apple store in his remote island in Spain or something like that and was stranded with an unbootable machine, because he needed old CPUs first so he could flash it.

[doublepost=1470843664][/doublepost]

The post explains that. Washers come in different thickness. A total stacked height height of 2.2mm is ideal because it's ultra-close to the height added by the lid, 2.5 is the max recommended height (taller than that and you might start approaching heights where the heatsink doesn't reach the CPU lid).* You MUST raise the heatsinks by 2.2-2.5mm via washers so that you avoid crushing the CPU and destroying your motherboard. 2.2-2.5mm? Why the difference in thickness?

It's more like a warning not to go mental with the overtightening.* You MUST NOT overtighten the screws, even when using washers! Hand-tighten them very gently and don't be afraid to leave a small gap between the heatsink and the washers; even the stock machine has a small gap between the heatsink and the pegs/posts. Your washers are just your emergency-rescue against idiocy! What matters is that you tighten with the CPU LID as your tightness reference, NOT the washers! Just a couple of turns will hold the heatsinks in place. You don't want to crush the CPU! Even with all the precautions in place you can still break your mac by crushing the CPU tray. With delidded CPU's you can just follow the apple repair manual and not worry about crushing the CPU's.

The only thing you do is cut off a tiny plastic notch on the CPU fan connector so the connector is released and can reach the plug on the CPU tray. Nobody cares.* You MUST cut out room for the fan connectors, because if they don't connect your Case fans will run at 100% speed to compensate for what it thinks is a dead CPU-fan. What's more important, the value of your Mac or the CPU?

The post explains: 3.2mm if you want to stack it on top of the existing strips, or 5mm for a total replacement (but that thickness is hard to find).* You MUST add extra-thick thermal strips for the voltage regulators, so that the heat they generate transfers to the heatsink. How thick is "extra-thick"?

Last edited:

And yes, people who install 6-core CPUs in unflashed machines cannot boot and have to take their machines to Apple to rescue them (by installing older CPUs, then flashing, then installing the 6-cores). Plenty of people had to do that in the netkas thread. One poor guy had no Apple store in his remote island in Spain or something like that and was stranded with an unbootable machine, because he needed old CPUs first so he could flash it.

It's hard to believe this can happen. In normal situation, the "failed" upgrade process should be as follow.

1) own a properly working 4,1.

2) buy a new CPU.

3) swap it (and the user forget the flash the firmware before that)

4) try to boot right after the upgrade, but unsuccessful.

.......

At that moment, the old CPU should still on his hand!!! All he has to do is just put the old CPU back in and flash the 4,1.

Thanks for the offer, I just got two E5520 for $3.5 on ebay, but it was a silly buy since I found out that the backplane is the one that gets flashed not the CPU board, I just needed to get a new processor board, I'm trying to decide where to buy it, there are none on ebay and not sure which online stores are actually good, there is this place called macpalace that sales it at 375 against the 550 of dvwarehouse....any recommendations?

Mac palace is a scam. I had a board go out and tried to get it from them when it showed $275 they came back and offered a new one for $500. I was like, no wand walked away. I couldnt find them anywhere at this point so just watched ebay and got one for $200. (mind you this is a long time ago, like 1 1/2 years). I'd suggest putting the new processors in (5520s) then take it into apple and have them replace the processor board. It'll be cheaper than $500.

Also did you get the plastic spacers with your processors? If not you need those to install the oem processors and im sure where you can buy them if they didnt come with your ebay auction.

I was also looking at your photos and on cpu a area it looked a little burnt at the bottom, this could be because of the photos lighting.

I also would suggest only connecting CPU A with one processor to try and see if you can get it to post, if you can get it to post then swap the processors and see if you can get it to post. If it posts then you know both processors are good, the next step it to connect processor B and try and get it to post.

These processors are finicky and even without the lids they need to be adjusted just right. If one bolt is 1mm to high, or its not level it wont post. All bolts have to be tightened down with exactly the same pressure.

Last edited:

It's hard to believe this can happen. In normal situation, the "failed" upgrade process should be as follow.

1) own a properly working 4,1.

2) buy a new CPU.

3) swap it (and the user forget the flash the firmware before that)

4) try to boot right after the upgrade, but unsuccessful.

.......

At that moment, the old CPU should still on his hand!!! All he has to do is just put the old CPU back in and flash the 4,1.

I agree, but I remember that he had a good reason why he didn't have the original CPUs. Perhaps he bought a Mac Pro without CPU tray and then added one with too-modern CPUs already installed.

[doublepost=1470852077][/doublepost]

These processors are finicky and even without the lids they need to be adjusted just right. If one bolt is 1mm to high, or its not level it wont post. All bolts have to be tightened down with exactly the same pressure.

Gravity takes care of the CPU making contact with the pins. The heatsink bolts don't need to be tight at all. The only thing that tightening them does is to push the heatsink closer to the CPU to make better heat contact.

Gravity takes care of the CPU making contact with the pins. The heatsink bolts don't need to be tight at all. The only thing that tightening them does is to push the heatsink closer to the CPU to make better heat contact.

Yes gravity does help, but without precise contact you could end up with the heat spreader not making contact with all parts of the cpu, then if one side is higher than the other you have issues with the processor smashing into the board in some areas.

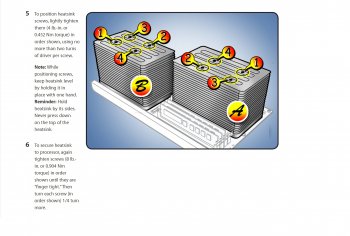

Even the service manual says to torque it down to 4lbs -in or 0.452nm of torque.

A simple google search will bring it up

Attachments

Last edited:

I just got two CPUs and a new board to test, but I think I need to replace the silicone thermal pad that was already on the heat sinks, it looks quite old. I know that 5mm would be if I had the CPUs with IHS, but would a 2mm thermal pad be enough? If so, which one would you recommend? I am having a difficult time picking one since I have no idea what the differences are other than thickness. Any links would be appreciated.

Thanks again, and I hope I can resurrect this beast!

UPDATE: I found these: http://www.digikey.com/short/3mdn9d

But as you can see the price gets higher as the thermal conductivity becomes better, as you can imagine, spending $58 on two strips of thermal pad is a little crazy, but then again, the conductivity seems to be the highest unless you go over to the max for over $100.

What would be the minimum that I should use as far as conductivity? Any Ideas?

Thanks again..

Thanks again, and I hope I can resurrect this beast!

UPDATE: I found these: http://www.digikey.com/short/3mdn9d

But as you can see the price gets higher as the thermal conductivity becomes better, as you can imagine, spending $58 on two strips of thermal pad is a little crazy, but then again, the conductivity seems to be the highest unless you go over to the max for over $100.

What would be the minimum that I should use as far as conductivity? Any Ideas?

Thanks again..

Last edited:

I just got two CPUs and a new board to test, but I think I need to replace the silicone thermal pad that was already on the heat sinks, it looks quite old. I know that 5mm would be if I had the CPUs with IHS, but would a 2mm thermal pad be enough? If so, which one would you recommend? I am having a difficult time picking one since I have no idea what the differences are other than thickness. Any links would be appreciated.

Thanks again, and I hope I can resurrect this beast!

Never done this, but I would think 3mm pad, not 2mm pad. My logic:

CPU 3mm + IHS 2mm = 5mm pad

CPU 3mm + no IHS = 3mm pad

Never done this, but I would think 3mm pad, not 2mm pad. My logic:

CPU 3mm + IHS 2mm = 5mm pad

CPU 3mm + no IHS = 3mm pad

I get what you're saying but following the thread here: http://forum.netkas.org/index.php/topic,852.msg24313.html#msg24313

If you read on the thermal pad instructions, he says:

"Get 3-3.2mm pads, and just lay the 3mm thick pads on the voltage regulator chips, and they'll bridge the gap to the existing pink 2mm pads on the heatsinks."

The ones I took of off the heatsinks were so worn down that they were less than 1mm.

But even if I were to get a thicker pad & compress it, the issue is thermal conductivity, for 6.0 W/m-K I have to pay over $60 with shipping. The only thing that I can rationalize enough to get this part would be that the board is new and so are the voltage regulators, so if I were to buy a better pad they would last longer....I wish I knew some electrical engineers :\

I get what you're saying but following the thread here: http://forum.netkas.org/index.php/topic,852.msg24313.html#msg24313

If you read on the thermal pad instructions, he says:

"Get 3-3.2mm pads, and just lay the 3mm thick pads on the voltage regulator chips, and they'll bridge the gap to the existing pink 2mm pads on the heatsinks."

The ones I took of off the heatsinks were so worn down that they were less than 1mm.

But even if I were to get a thicker pad & compress it, the issue is thermal conductivity, for 6.0 W/m-K I have to pay over $60 with shipping. The only thing that I can rationalize enough to get this part would be that the board is new and so are the voltage regulators, so if I were to buy a better pad they would last longer....I wish I knew some electrical engineers :\

If a 3mm pad is the right size to mate to the existing 2mm pad, but that existing 2mm pad has compressed to 1mm, why do you want a 2mm pad? It sounds like you need a 4mm pad to mate to the now-1mm pad?

Or if you want to remove the old pad, then you need a 5mm pad for the total? Or a combined 3mm pad plus 2mm pad? The correct size(s) should be incredibly simple math for either of us, but I guess I don't fully understand what you are trying to do.

In any case, once you figure out what size you are aiming for, get a pad from modDIY.com. They have 0.5 to 5.0 mm thicknesses and reasonable pricing. The price you are quoting is outrageous. Fujipoly Extreme is 6W/mk, but verify by Googling the part number once you've picked a size.

http://www.moddiy.com/search.php?search_query=fujipoly&x=0&y=0

If a 3mm pad is the right size to mate to the existing 2mm pad, but that existing 2mm pad has compressed to 1mm, why do you want a 2mm pad? It sounds like you need a 4mm pad to mate to the now-1mm pad?

Well, after all the trouble I've been with this purchase, I know that this guy also messed up the thermal padding, in a normal setting I am sure a 2mm or even a 2.5mm would be sufficient, otherwise it would compress too much and spill over other components.

I took a look at those pads you linked, but size is too small, you need about 10 cm by 10 cm to actually cut it to fit the shape. So they are about the same price, maybe a little bit cheaper but modmy does not sell them, I found them at: http://www.frozencpu.com/cat/l3/g8/...ermal_Pads_Tape-Thermal_Pad_-_20mm-Page1.html

I think i'm going to measure the distance without it with a caliper and then buy whatever fits better.

Thanks for the help!

databaze: Sounds like someone has overcompressed those pads a lot on your heatsinks. I agree with doing a total replacement with a 5mm pad in your situation. Also note that the new pads are very soft and compressible, so you do not need to measure distance. They will compress.

For my own job I bought a 10cm x 10cm pad and it was very expensive ($35). I ended up using about 20% of it, to cut out two 1cm(or so) x 10cm strips.

You should be able to get a smaller 5cm x 5cm (5mm tall) pad to save money, cut out four 1cm x 5cm strips, and then just lay two strips next to each other, so instead of [----10cm----] per heatsink, you would have [---5cm---][---5cm---]. As long as you ensure that the gap is "in the air" between two chips, there is no difference in thermal transfer.

And yes... silicon pads are freaking expensive. Now I understand why boob jobs are so pricy.

For my own job I bought a 10cm x 10cm pad and it was very expensive ($35). I ended up using about 20% of it, to cut out two 1cm(or so) x 10cm strips.

You should be able to get a smaller 5cm x 5cm (5mm tall) pad to save money, cut out four 1cm x 5cm strips, and then just lay two strips next to each other, so instead of [----10cm----] per heatsink, you would have [---5cm---][---5cm---]. As long as you ensure that the gap is "in the air" between two chips, there is no difference in thermal transfer.

And yes... silicon pads are freaking expensive. Now I understand why boob jobs are so pricy.

But why would you recommend using 5mm pads when i have chips without IHS? I mean I get it when you're using the ones with it and need to put the washers and stuff, but yesterday i measured the distance between the voltage regulators and the heatsink and it is less than 1mm when sitting on the cpu.databaze: Sounds like someone has overcompressed those pads a lot on your heatsinks. I agree with doing a total replacement with a 5mm pad in your situation. Also note that the new pads are very soft and compressible, so you do not need to measure distance. They will compress.

For my own job I bought a 10cm x 10cm pad and it was very expensive ($35). I ended up using about 20% of it, to cut out two 1cm(or so) x 10cm strips.

You should be able to get a smaller 5cm x 5cm (5mm tall) pad to save money, cut out four 1cm x 5cm strips, and then just lay two strips next to each other, so instead of [----10cm----] per heatsink, you would have [---5cm---][---5cm---]. As long as you ensure that the gap is "in the air" between two chips, there is no difference in thermal transfer.

And yes... silicon pads are freaking expensive. Now I understand why boob jobs are so pricy.

EDIT: I just called and those fujipoly pads do not have adhesive on one side, not sure that would work considering that it needs to stay in place.... I found one that comes with one side adhesive but its about $60 with shipping....

Last edited:

Some fools keep the lids but do not add washers (pindelski or something was one of those idiots, luckily he has deleted his guides) and the result is the image you posted above...

i'm not sure what your issue is - I have mine also running without additional washers/height and using lid CPUs, if you don't put it on hard - experience is key, especially with crap servers of first/second gen Xeon - there is not much risk involved.

First try, every time. Just once i thought i ****ed up but no - The CPUs i got were simply not supported (X5687 BABY!), others - first try, no issue.

William_si: The issue is - Just put washers there and you never risk damaging anything. The aversion to washers is so weird.

Done, got the expensive pads with adhesive on one side 2mm, hopefully it works. I think i may be able to test over the weekend if it ships today. Will report back.

UPDATE: I got the new board, got it all together, put the board back in, and:

1- The two CPU red leds stay lit even when I got the two CPUs in and everything seems to be ok.

2-When I turn of the machine, I get the red LED for OVTMP CPUB o the backplane board.

What I tried:

I took the cpu/fan assembly off and inserted the bare board without CPU or RAM, of course the two RED CPU leds stay lit due to no CPU, but here is the weird thing: The OVTMP CPUB light turns on when I just the machine down, even without a CPU???

I have no idea what to do, really, I read the service manual and nothing, I am not sure now if it has to do with a bad backplane board, or if its this new board that was not working from the get go, really, I have no idea what to do.

Any of you have any tips, recommendations, etc?

I would really really appreciate it. I am desperate....

1- The two CPU red leds stay lit even when I got the two CPUs in and everything seems to be ok.

2-When I turn of the machine, I get the red LED for OVTMP CPUB o the backplane board.

What I tried:

I took the cpu/fan assembly off and inserted the bare board without CPU or RAM, of course the two RED CPU leds stay lit due to no CPU, but here is the weird thing: The OVTMP CPUB light turns on when I just the machine down, even without a CPU???

I have no idea what to do, really, I read the service manual and nothing, I am not sure now if it has to do with a bad backplane board, or if its this new board that was not working from the get go, really, I have no idea what to do.

Any of you have any tips, recommendations, etc?

I would really really appreciate it. I am desperate....

UPDATE: I got the new board, got it all together, put the board back in, and:

1- The two CPU red leds stay lit even when I got the two CPUs in and everything seems to be ok.

2-When I turn of the machine, I get the red LED for OVTMP CPUB o the backplane board.

What I tried:

I took the cpu/fan assembly off and inserted the bare board without CPU or RAM, of course the two RED CPU leds stay lit due to no CPU, but here is the weird thing: The OVTMP CPUB light turns on when I just the machine down, even without a CPU???

I have no idea what to do, really, I read the service manual and nothing, I am not sure now if it has to do with a bad backplane board, or if its this new board that was not working from the get go, really, I have no idea what to do.

Any of you have any tips, recommendations, etc?

I would really really appreciate it. I am desperate....

Wow sounds like a huge headache! where do you live maybe someone locally can help?

Did you install the original 4 core processors that you bought from ebay? Or are you trying to install the 6 core ones? If so try the 4 core ones since the 6 cores could be bad after what happened. You can only rule out those chips once you get it all up and running with the original 4 cores you can proceed to trying the 6 cores.

Also when installing the processors, do one at a time. Meaning install processor A and when you get it to chime and bootup to OSX shut down the computer and proceed to processor B. With one processor you'll have the fan on at full speed, but just ignore that since its because your missing one of the processors.

Did you get new fans with the new tray? if so try the old ones if you used the new ones. Another tip, remove all your ram and only install matching ram in slots 1 and 5 leave the rest empty.

Also try a Pram reset.

Ok, so I went a little crazy since I had a really bad day and then coming home to this was the last drop, well, I just said F*#$ it and did the following:

Grabbed the old board and installed the old CPU's onto it, just like that with the already on thermal paste on cpu and heatsink and i did not count how many turns i gave to the cpu and i just went with it until i was like maybe one more will break this sh@*%. Plugged the old board into the case and WTF it turned on! I got kernel panics but it TURNED ON!!!

After I saw that the old board was giving kernel panics non stop i thought, well, this has to be related to the bent pins so lets put the new board and do the same, just fuc@# it.

So i did, and IT TURNED ON!! But without kernel panics!! So now i have it working but I am afraid that since I did not reapply the thermal paste again and kept on just swapping and trying, swapping and trying this and that, the temp is going to get weird.

I started monitoring the CPU temp with a tool I have and I see I have a 9 to 10 degree difference between the Diodes/Heatsink/Core PCECI between CPU A & B. Not sure if this is normal of if both CPUs should be the same.

Benchmark:

Grabbed the old board and installed the old CPU's onto it, just like that with the already on thermal paste on cpu and heatsink and i did not count how many turns i gave to the cpu and i just went with it until i was like maybe one more will break this sh@*%. Plugged the old board into the case and WTF it turned on! I got kernel panics but it TURNED ON!!!

After I saw that the old board was giving kernel panics non stop i thought, well, this has to be related to the bent pins so lets put the new board and do the same, just fuc@# it.

So i did, and IT TURNED ON!! But without kernel panics!! So now i have it working but I am afraid that since I did not reapply the thermal paste again and kept on just swapping and trying, swapping and trying this and that, the temp is going to get weird.

I started monitoring the CPU temp with a tool I have and I see I have a 9 to 10 degree difference between the Diodes/Heatsink/Core PCECI between CPU A & B. Not sure if this is normal of if both CPUs should be the same.

Benchmark:

Last edited:

Register on MacRumors! This sidebar will go away, and you'll see fewer ads.