@ezugaru asks:

"Bro, what do you mean by that? The other components have to touch the heatsink trought the pads or k5?"

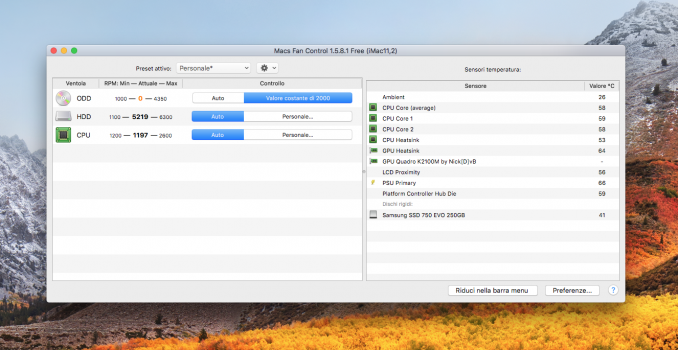

the way the heat sink maintains contact with the GPU is through the springs on the screws which bolt the card to the heat sink. The springs allow the assembly to expand and contract with temperature while maintaining contact.

However, it is critical that there are no gaps between the GPU chip and the heat sink. The role of the thermal compound (I use Arctic Silver 5) is to eliminate any gaps, even tiny gaps. The Arctic Silver site

www.arcticsilver.com

which describes the "surface spread" method that I use... but the caution to completely clean the surface, don't apply with your fingers, and keep dust and hair off the application, all these things greatly reduce the heat conductivity.

If you put something on the other components on the board as a contact to the heat sink, what ever it is should NOT resist against the heat sink. For instance, if there is a

nominal 0.4mm clearance and you put an 0.6mm thermal pad that resists the heat sink spring, the heat sink may not contact the GPU.

That is why the K5 thermal compound is preferred for these other components, it has no mechanical strength and will not resist the heat sink spring.

Finally, when using some compounds like Arctic Silver 5 care must be taken not to put too much on, as the material can act as a capacitive short if it contacts chip leads and/or circuit board traces.

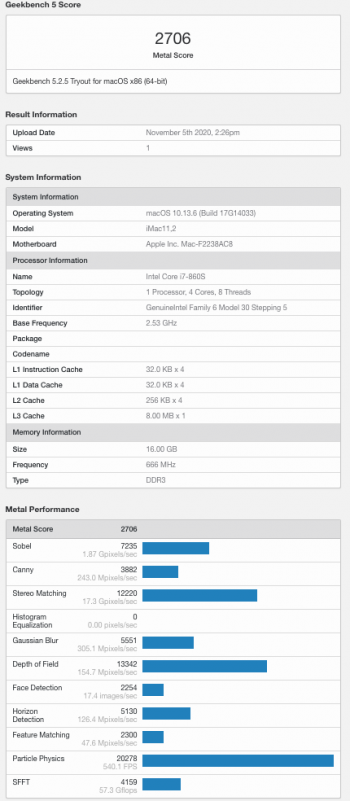

The heat management on these machines (and most Apple products) is very sophisticated and care must be taken when re-assembling the components in order to realize the optimum thermal performance.