[QUOTE = "skriatok, publicación: 28732863, miembro: 1225115"]

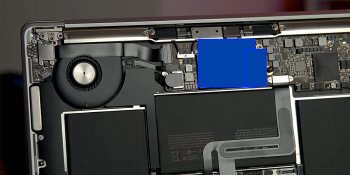

Para ser honesto, tu ejecución fue desordenada y yo contaba días, cuando la matas. Las ideas eran un punto excelente, que cruzó muchas mentes, pero cuando miro esas fotos, nunca las tomaría como punto de referencia, es su máquina y ya hay ejecuciones casi limpias.

La transferencia de calor con papel de aluminio es inadecuada.

[/CITAR]

Naciones Unidas

Aluminio ???? Es estaño

Para ser honesto, tu ejecución fue desordenada y yo contaba días, cuando la matas. Las ideas eran un punto excelente, que cruzó muchas mentes, pero cuando miro esas fotos, nunca las tomaría como punto de referencia, es su máquina y ya hay ejecuciones casi limpias.

La transferencia de calor con papel de aluminio es inadecuada.

[/CITAR]

Naciones Unidas

Aluminio ???? Es estaño