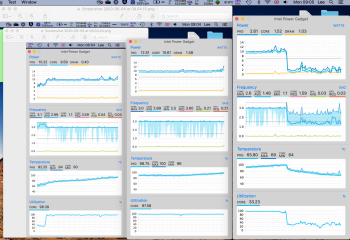

Want to add to the pile of results with some developments I've had with my 2018 MBA here. I've applied Arctic MX-4 thermal paste to the die replacing the Arctic Silver 5 I've applied prior (marginal temps/performance differences with the changes and maybe an extra 100 - 150 points at most on GB5 tests on hard flat surfaces). and temps remained similar to stock with idle temps around 45 - 55C with the usual 100c dumpster fire it usually is.

NOTE: these general results and experiences are in a room with an ambient temperature of around 65F - 68F. I like it cold and will specify if the ambient temp is different as my office at work is a higher temp and comes into play at the end. Each paragraph is a slightly different mod and the experience that followed.

Insulator removal

The next change was the removal of the thermal insulator on the bottom cover, with the insulator removed there was less heat transferred to the bottom case and the temps seemed to drop much faster when they did spike due to usage demands. Slight increase in scores over in GB5 and during sustained loads (parallels Win10 (idling on the desktop), Safari 4 - 7 tabs) temps never stayed at 100C very long and once normalized sat around 88C give or take a few degrees.

Thermal pad (unique size/placement) no insulator

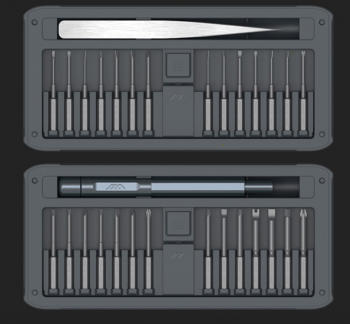

Following the above I decided to apply a thermal pad to the heatsink to form a connection to the bottom cover. I purchased a 6W/m.k ADWIT thermal pad. 1.5mm seemed to be just a hair over the thickness of the original insulator and fit perfectly. I cut a piece to fit perfectly square between the heatsink's mounting screws themselves to leave room for airflow over the edge fins. Temps never exceeded 81C with Safari (4 tabs), and Win10 in parallels with two moderately intensive Unity games running.

At this point the i5 seems to level out at 1.5/1.6GHz after a sustained load is, well, sustained for more than about 4min. Fans never ramp up, at all. They sit at 3k or below maintaining these temps and clock speeds (these clock speeds appear to be hard coded limits on my machine). Now the downside. With this direct contact, AND the thermal pad being directly over the relative center of both dies under the heatsink, the bottom gets very, very hot after a sustained load at 80C for about 5min. So hot that it smells like heated aluminum and WILL cause a burn over a relatively short amount of time. Ramping to 8k on the fans doesn't lower temps beyond 77C.

Thermal pad (unique size/placement) no insulator (ALTERED)

Way, too hot for me. My next idea was this. Combine the benefits of the removed insulator and thermal pad to fully utilize both approaches in a more, elegant way. So I cut two narrow strips of thermal pad the length of the heatsink and the width of the edge of the heatsink to the outer edge of the mounting screws. I laid these pieces along the longest sides of the heatsink to maximize contact between the heatsink and bottom cover, while maximizing airflow over the hottest areas, i.e. directly above the locations of the die.

Final results

With the above, I've gained the best temp/comfort levels I think are possible, with the least invasive approach on this model. I have at this moment 3 tabs in safari, 19 chrome tabs (note that 6 of these tabs are in a wrapper via Wavebox), Notes, stocks, and Discord. My temps with the machine in an office with the ambient temp around 72F, sitting on my legs (bottom of the case is closer to tepid if I had to describe it now.) for the time it took to write this is 35 - 40C (short spikes to 50C when changing windows), zero rpm. It has not hit over 72C today that I've noticed and when it has spiked to near said temps it lowers immediately. Fans haven't come on once today, even while watching videos 720p - 1080p. All the while the machine is sitting on the velour/felt style sleeve I use, not the hard wood of my desk.

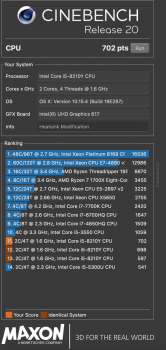

Final max temp I've seen, 81C under heavy use that wouldn't be normal for a MBA (see above). Highest temps on a benchmark, 100C for very, very short periods of time, averages around 95 - 99C when running intensive benchmarks.

/wall I'll rewrite this later to be more eloquent...