@185…….

You make an important point which potential upgraders should try and understand…….

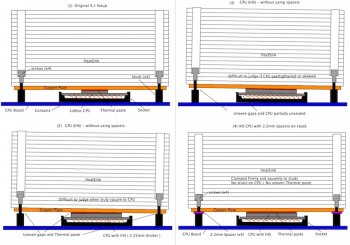

In the original arrangement - i.e. with de-lidded processors the heatsink screws pull fully home (mechanically) onto the four stand-off studs and the copper plate sits firmly on the wider 'lands' on those studs and is pulled down tight onto them.

As such, a prescribed torque setting is appropriate because the mechanical arrangement is carefully designed to seat (but not overly squash) the processor(s) in their sockets.

If replacing with de-lidded cpus there is no difference, the same hardware works.

If replacing with lidded versions you cannot rely on the above unless you pack the standoff studs with carefully measured, non-compressible spacers that are equivalent to the difference in height between the two types of CPU ( 2.24mm I believe). This way the heatsinks can be fully but gently tightened because, while not identical, the error in 'gapping' is likely to be reduced to about 0.05mm - which I suspect is OK for our purposes.

Counting turns of the screws may well work but its a bit too hit n miss for my liking AND it relies on squashing the CPU itself to get any firmness at all on the heatsink screws……… which strikes me as a bad thing.

??

TAMM

You make an important point which potential upgraders should try and understand…….

In the original arrangement - i.e. with de-lidded processors the heatsink screws pull fully home (mechanically) onto the four stand-off studs and the copper plate sits firmly on the wider 'lands' on those studs and is pulled down tight onto them.

As such, a prescribed torque setting is appropriate because the mechanical arrangement is carefully designed to seat (but not overly squash) the processor(s) in their sockets.

If replacing with de-lidded cpus there is no difference, the same hardware works.

If replacing with lidded versions you cannot rely on the above unless you pack the standoff studs with carefully measured, non-compressible spacers that are equivalent to the difference in height between the two types of CPU ( 2.24mm I believe). This way the heatsinks can be fully but gently tightened because, while not identical, the error in 'gapping' is likely to be reduced to about 0.05mm - which I suspect is OK for our purposes.

Counting turns of the screws may well work but its a bit too hit n miss for my liking AND it relies on squashing the CPU itself to get any firmness at all on the heatsink screws……… which strikes me as a bad thing.

??

TAMM