Thank you @guiguigui, what I hoped wouldn't happen indeed did. Yes sure I could buy material from amazon, eBay but I didn't, this whole project has been put to a small aerospace firm for a simple proof of concept, all at my risk and expense. I don't control their cost or have the ability to negotiate the cost of the material or the size needed to fit their cutting machine. Oh and yes 20% VAT is placed on top as well.Don't wanna turn the thread into an emotional dispute, but from my point of view all contributions are GREAT.

Both @srkirt and @Loog (and a lot of other users here) have been working big to improve our machines.

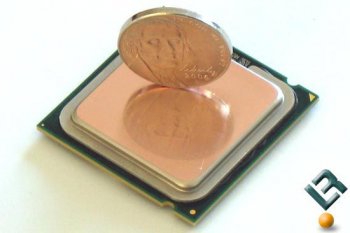

No one is branding the improvement as their own, please don't take it personally... I mean, we are talking about the disruptive discovery of copper shims thermal properties (WTF?!).

If someone makes a business out of it I don't think posting it on a public forum is the way to go... Or at least I'd not complain if someone tries to go for it lol. Welcome to opensource development.

That said, if you think it's an opportunity, make a business. It's a free world. At the end you'll make money if people perceives value in your product. Otherwise you'll go broke.

If you think it's not an opportunity to make a business, but to help the community, you can try to manufacture it at zero profit (this is what @Loog is doing btw. If you don't trust him you can get material supply, cut your own sheets, setup all delivery, handle all the logistics of the process and report the costs).

And if you don't like other people working on your ideas don't make them public, it's that easy.

Thinking about the community it seems a big improvement from Loog to spend his time and money to get a perfect cut shim to fit our machine. Some users might be doubting about implementing the mod or not. This will hopefully motivate them to do it with a more 'out of the box' solution that you don't have to cut on your own.

I'm expecting more people to test it, share their process and standardize it somehow, get to the perfect thickness between 0.5-0.3. Get a bigger sample of users posting their improvements in performance/temperatures.

Thanks everybody for your time and energy!

If you want to try one, drop me a line and please leave your feedback for everyone to see, if you want to buy others and cut them down, that's the most cost effective way, that's what I've done. If you want the dimensions to make your own either in a garage or local engineering shop they are 16.5mm x 22mm 0.3mm/ 0.5mm with a 2mm radius. Set to be 1 size to fit both MBA to keep POC costs to a minimum.

As for I can but 10 units for $8 shipped ... how many machines do you guys have? ... and does $2 price difference equate to 10 mins of your time to make these shims fit when on balance making from raw material? Is this worth while when they are cheaper than a cup of coffee at your local coffee shop on balance? Large scale production would be cheaper, remember these are just a POC!!

Thanks to @srkirt for the early pioneering of this.

Stay safe everyone.

Last edited: