Got a tip for us?

Let us know

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

MBP 1,1-10,2 GPU Kernel Panic in mid-2010; what's the best fix?

- Thread starter groverb

- Start date

- Sort by reaction score

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Guys! My macbook came back to life, but I would like to set up the capacitor, can I use the one in this link? I can not find this to sell in Brazil ...

http://produto.mercadolivre.com.br/...smd-tntalo-330uf-25v-substituico-nectokin-_JM

http://produto.mercadolivre.com.br/...smd-tntalo-330uf-25v-substituico-nectokin-_JM

Guys! My macbook came back to life, but I would like to set up the capacitor, can I use the one in this link? I can not find this to sell in Brazil ...

http://produto.mercadolivre.com.br/...smd-tntalo-330uf-25v-substituico-nectokin-_JM

E aí, bro...

comprei esses aqui, estão em viagem

http://www.ebay.com/itm/PANASONIC-E...251533&hash=item2a593a5fba:g:0mgAAOSwmrlUtsLq

Esquece os de tântalo, vão funcionar por um tempo mas depois vão espanar outra vez.

Esses são maiores que o original, tem que fazer o esquema de raspar a placa mãe. Trash, vou fazer me borrando todo haha.

O fabioroberto, que desvendou a treta do fix por software me disse que na placa mãe do Lenovo Ideapad S10-2 tem dois desses, no ML tem umas com defeito por 40 reais pra retirar peça. Eu optei por comprar novo mesmo.

Abraço.

Obrigado Rafael! Raspar a placa mãe :O vou falar com o meu sogro que entende melhor disto, mas vou providenciar a compra da peça! =DE aí, bro...

comprei esses aqui, estão em viagem

http://www.ebay.com/itm/PANASONIC-E...251533&hash=item2a593a5fba:g:0mgAAOSwmrlUtsLq

Esquece os de tântalo, vão funcionar por um tempo mas depois vão espanar outra vez.

Esses são maiores que o original, tem que fazer o esquema de raspar a placa mãe. Trash, vou fazer me borrando todo haha.

O fabioroberto, que desvendou a treta do fix por software me disse que na placa mãe do Lenovo Ideapad S10-2 tem dois desses, no ML tem umas com defeito por 40 reais pra retirar peça. Eu optei por comprar novo mesmo.

Abraço.

Obrigado Rafael! Raspar a placa mãe :O vou falar com o meu sogro que entende melhor disto, mas vou providenciar a compra da peça! =D

Hahaha é, raspar ela pra aumentar a área. Estes caps de alumínio são um pouco maiores, aí tem que aumentar a região de solda.

Da uma olhada nos primeiros posts, tem vídeos do Louis Rossmann fazendo a troca e mostra uma raspagem. Bem como muita informação de forma geral. Tem os fixes paliativos por software e estes vídeos e fotos de reparos que a galera fez.

Abraço.

To vendo aqui! Vai ficar filé!Hahaha é, raspar ela pra aumentar a área. Estes caps de alumínio são um pouco maiores, aí tem que aumentar a região de solda.

Da uma olhada nos primeiros posts, tem vídeos do Louis Rossmann fazendo a troca e mostra uma raspagem. Bem como muita informação de forma geral. Tem os fixes paliativos por software e estes vídeos e fotos de reparos que a galera fez.

Abraço.

E não esqueça de usar um bom fluxo, específico para solda eletrônica. Pode adquirir em uma boa eletrônica.To vendo aqui! Vai ficar filé!

Hi Daniele,

I've got a few left from my own repair. They work just perfect. I'd be glad helping and sent you one for free. I'm new to this Forum, but a personal Mail should be possible.

Just drop me a personal Mail with your address.

Regards

Volker

Volker,

excuse my delay.

If your offer is always valid, as I hope, could you write me your email so we can solve this?

Thank a lot!!!

Ciao Daniele

so I tried the Kext tool, thanks fabioroberto, however getting some wonky behavior, just want to see if there is anything else I could or should do that might eliminate the wonky behavior. I haven't gotten any kernel panics since using it, and I've run it through cinebench and other stuff that should. So thats good. However, a few apps misbehave in a way that they don't when i use gfxCardStatus in integrated-only mode. For example, if I use VMWare Fusion and put it full screen, the computer starts spinning and gets stuck on that full screen. I get the same problem with Remote Desktop connection to another mac in full screen mode. I'm also using Totalspaces, which could be the culprit too.

Had some other apps that normally work fine, decide to "not respond" since messing around with all this stuff, I'm not sure if its from my previous attempts to do the nvram trick mentioned on some other threads (I already reset nvram so I doubt it), or from switching from gfxCardStatus to the kext trick here. I would really like to get this working 100% because I feel it should be better overall compatability to run in dynamic switching mode...albeit a bit slower with this kext hack....compared to running gfxCardStatus in integrated only mode. However, like I said, my computer has really been acting funny since trying this approach, no kernel panics per say, but just some wonky behavior that I can't explain other wise. Switching back to gfxCardStatus for a while to compare.....

any suggestions welcome..

Had some other apps that normally work fine, decide to "not respond" since messing around with all this stuff, I'm not sure if its from my previous attempts to do the nvram trick mentioned on some other threads (I already reset nvram so I doubt it), or from switching from gfxCardStatus to the kext trick here. I would really like to get this working 100% because I feel it should be better overall compatability to run in dynamic switching mode...albeit a bit slower with this kext hack....compared to running gfxCardStatus in integrated only mode. However, like I said, my computer has really been acting funny since trying this approach, no kernel panics per say, but just some wonky behavior that I can't explain other wise. Switching back to gfxCardStatus for a while to compare.....

any suggestions welcome..

Does not make sense to be the edited kext. I had the opportunity to run Fusion and Remote Desktop and these problem didn't happen.so I tried the Kext tool, thanks fabioroberto, however getting some wonky behavior, just want to see if there is anything else I could or should do that might eliminate the wonky behavior. I haven't gotten any kernel panics since using it, and I've run it through cinebench and other stuff that should. So thats good. However, a few apps misbehave in a way that they don't when i use gfxCardStatus in integrated-only mode. For example, if I use VMWare Fusion and put it full screen, the computer starts spinning and gets stuck on that full screen. I get the same problem with Remote Desktop connection to another mac in full screen mode. I'm also using Totalspaces, which could be the culprit too.

Had some other apps that normally work fine, decide to "not respond" since messing around with all this stuff, I'm not sure if its from my previous attempts to do the nvram trick mentioned on some other threads (I already reset nvram so I doubt it), or from switching from gfxCardStatus to the kext trick here. I would really like to get this working 100% because I feel it should be better overall compatability to run in dynamic switching mode...albeit a bit slower with this kext hack....compared to running gfxCardStatus in integrated only mode. However, like I said, my computer has really been acting funny since trying this approach, no kernel panics per say, but just some wonky behavior that I can't explain other wise. Switching back to gfxCardStatus for a while to compare.....

any suggestions welcome..

Turn off gfxCardStatus, enable Automatic graphics switching and test again.

Good luck.

Does not make sense to be the edited kext. I had the opportunity to run Fusion and Remote Desktop and these problem didn't happen.

Turn off gfxCardStatus, enable Automatic graphics switching and test again.

Good luck.

Well that's the test I already did.

Yesterday afternoon I successfully implemented the hardware fix. I don't advocate the method I used unless you're willing to experiment with brute force knowing that your logic board might not survive. Turns out that my board was able to tolerate more abuse than I thought. I don't consider myself an Apple FanBoy but the reason I was willing to pay $2500 for this machine back in 2010 is because I was sold on what it could do (switching between the graphics processors was something that immediately caught my attention) and believed it would be the last and only machine I would ever need to buy. They are very upgradable and I guarantee that with 8gb ram and a SSD they exceed modern performance standards even though Apple considers them vintage. But the Tantalum Capacitor issue makes them underperform below what is acceptable today. The patch works but if you want to preserve the performance that sets this machine apart, you must do the hardware fix.

I don't have sophisticated soldering equipment - just a $15 iron and $10 solder sucker I've had for decades. Here is how I replaced the capacitor:

1. Bought the right capacitor from http://www.mouser.com/search/ProductDetail.aspx?r=667-EEF-CX0D331R

2. Removed the logic board according to this video (once you get the bottom off, logic board removal is the same):

3. Watched Louis Rossmann's video to see how to do it the RIGHT way (except he mistakenly reversed the polarity. When you do it make sure the polarity bar (+) points to the inside of the board):

4. Using tweezers and patience, I pressed my hot solder iron on top of the bad capacitor and kept it there while forcefully nudging the bad capacitor until the solder sticking it to the board got hot enough to release it. Note that I was too aggressive at this step and ripped some of the + contact pad off the board. Lesson learned - be gentle and take your time. Thankfully there was a enough contact left for me to solder the replacement chip on.

5. Use solder wick and flux to clean the contacts. Rossmann does this a couple of times in his video.

6. Scraped off more gnd (-) contact area on the board like Rossmann did.

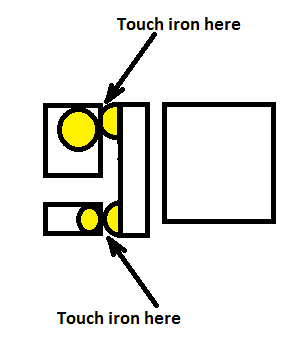

7. Pre-soldered 4 points: the board contacts and corresponding capacitor contacts. Use plenty of solder but not so much that the capacitor can no longer fit on its side next to the coil in the picture shown in post #25 on this thread marked "2R2 009 LJJ."

8. Used tweezers to drop the good capacitor on its side between the board contacts and the coil. Make sure the polarity is correct the way you drop in the good capacitor. It should be sitting at a right angle with solder between the board and capacitor contacts ready to melt together.

9. Solder the good capacitor into place with your iron. See file attachment. This should only require momentary contact between the board and capacitor solder contacts in two places (+ & -).

10. Put everything back together and enjoy the fix.

Disclaimer:

Note that even though these boards appear to be able to take a beating, YOU RUN THE RISK OF DAMAGING THE BOARD BEYOND REPAIR IF YOU DO IT THIS WAY. So before you do it, make sure you are willing to part with the board if it gets damaged.

I don't have sophisticated soldering equipment - just a $15 iron and $10 solder sucker I've had for decades. Here is how I replaced the capacitor:

1. Bought the right capacitor from http://www.mouser.com/search/ProductDetail.aspx?r=667-EEF-CX0D331R

2. Removed the logic board according to this video (once you get the bottom off, logic board removal is the same):

5. Use solder wick and flux to clean the contacts. Rossmann does this a couple of times in his video.

6. Scraped off more gnd (-) contact area on the board like Rossmann did.

7. Pre-soldered 4 points: the board contacts and corresponding capacitor contacts. Use plenty of solder but not so much that the capacitor can no longer fit on its side next to the coil in the picture shown in post #25 on this thread marked "2R2 009 LJJ."

8. Used tweezers to drop the good capacitor on its side between the board contacts and the coil. Make sure the polarity is correct the way you drop in the good capacitor. It should be sitting at a right angle with solder between the board and capacitor contacts ready to melt together.

9. Solder the good capacitor into place with your iron. See file attachment. This should only require momentary contact between the board and capacitor solder contacts in two places (+ & -).

10. Put everything back together and enjoy the fix.

Disclaimer:

Note that even though these boards appear to be able to take a beating, YOU RUN THE RISK OF DAMAGING THE BOARD BEYOND REPAIR IF YOU DO IT THIS WAY. So before you do it, make sure you are willing to part with the board if it gets damaged.

Attachments

Last edited:

Thanks for the update. I'm almost for sure going to send mine to Rossman and have it fixed. I'm scared to do it myself. If I can find someone local to do it for half the price of Rossman, maybe I will do that, but on the other hand, Rossman and a couple guys are the ones that figured this out, I don't mind paying him to do it.

4. Using tweezers and patience, I pressed my hot solder iron on top of the bad capacitor and kept it there while forcefully nudging the bad capacitor until the solder sticking it to the board got hot enough to release it. Note that I was too aggressive at this step and ripped some of the + contact pad off the board. Lesson learned - be gentle and take your time. Thankfully there was a enough contact left for me to solder the replacement chip on.

You really don't need to be that aggressive with it. I also used a pencil style iron... just heat the solder on one side of the cap and then lift up on that side just enough so it's not making contact with the board anymore. The capacitor leg still attached will easily bend... then just do the same on the other side.

You really don't need to be that aggressive with it. I also used a pencil style iron... just heat the solder on one side of the cap and then lift up on that side just enough so it's not making contact with the board anymore. The capacitor leg still attached will easily bend... then just do the same on the other side.

Thank you for all of you.

I have repaired my girlfriend's old macbook pro mid 2010 this morning.

I also ripped some of the + contact pad off the board but it is still working fine.

There is a small problem.

I have tried to fix it by software before but it doesn't works.

While after that, my battery indicator is missing.

Inside the power of system report, it shows only working with AC power.

I have formatted it and reinstalled the macOS but still missing the battery indicator.

Anyone know what should I do to get it back?

One more thing, did anyone update to macOS High Sierra?

I found that it cannot be config the touchpad.

I have repaired my girlfriend's old macbook pro mid 2010 this morning.

I also ripped some of the + contact pad off the board but it is still working fine.

There is a small problem.

I have tried to fix it by software before but it doesn't works.

While after that, my battery indicator is missing.

Inside the power of system report, it shows only working with AC power.

I have formatted it and reinstalled the macOS but still missing the battery indicator.

Anyone know what should I do to get it back?

One more thing, did anyone update to macOS High Sierra?

I found that it cannot be config the touchpad.

Hi,

which battery indicator ?

The icon in the menus bar, or the green diodes located on the side of the case ?

which battery indicator ?

The icon in the menus bar, or the green diodes located on the side of the case ?

...well, damn. It crashed again just a few minutes after trying the kext fix

Last edited:

Hi,

which battery indicator ?

The icon in the menus bar, or the green diodes located on the side of the case ?

The battery icon in the menu bar was missing.

I found out that the same problem as the below link.

https://discussions.apple.com/thread/3067544?tstart=0

But the solution in the link is not working to me.

Just find out that, it shows MacBook Pro Intel Core i5, Intel Core i7 (Mid 2010),

while my one should be i5 only.

First, do SMC and NVRAM resets.

https://support.apple.com/en-us/HT201295

https://support.apple.com/en-us/HT204063

https://support.apple.com/en-us/HT201295

https://support.apple.com/en-us/HT204063

First, do SMC and NVRAM resets.

https://support.apple.com/en-us/HT201295

https://support.apple.com/en-us/HT204063

I have did NVRAM reset but have not try SMC reset.

Thank you for your help.

Will let you know if the problem is solved or not.

Hi Guys,

did anyone of you try Mac OS High Sierra yet? Is the kext workaround still working?

Thanks for letting me know

btw: does anyone know a repair shop in germany for the capacitor fix? I never have done something like this before...

BR

did anyone of you try Mac OS High Sierra yet? Is the kext workaround still working?

Thanks for letting me know

btw: does anyone know a repair shop in germany for the capacitor fix? I never have done something like this before...

BR

Last edited:

Hi Guys,

did anyone of you try Mac OS High Sierra yet? Is the kext workaround still working?

Thanks for letting me know

btw: does anyone know a repair shop in germany for the capacitor fix? I never have done something like this before...

BR

Edit the .plist using the values from my first post: https://forums.macrumors.com/thread...010-whats-the-best-fix.1890097/#post-23312990

I have did NVRAM reset but have not try SMC reset.

Thank you for your help.

Will let you know if the problem is solved or not.

Just tried both SMC and NVRAM reset on my macbook pro.

But the problem is still the same.

[doublepost=1500566925][/doublepost]Oh, I finally figure it out the reason why it does not show battery on my macbook pro.

It is because I replaced the original apple battery with Chinese third party battery before.

Problem solved.

Thank you.

I had to re-apply this patch after updating to 10.12.6, but the update didn't re-enable SIP as I thought it might.

The machine crashed as SOON as 10.12.6 finished installing - I applied the update and restarted, and all has been well since!

The machine crashed as SOON as 10.12.6 finished installing - I applied the update and restarted, and all has been well since!

Register on MacRumors! This sidebar will go away, and you'll see fewer ads.