I'm waiting on mine to arrive and plan to mod it. Do you think theres a good aftermarket heatsink that could replace the stock one or are you going to try the thermal pad? I haven't personally used the thermal pads before. Edit: Just looked up how they are applied. Can these be safely cut down to fit the size of the CPU?Made an account just for this.

First of all, the fanboying in this thread is silly. The machine clearly runs hot for real workloads. Nobody is impressed that your machine runs at 50 degrees while doing a workload your iphone could do just as well. Thank you mods for clearing up some of the engineering talk the first half of the thread, it was horrible reading back and forth for 20 pages without anybody actually trying to fix the problem. In the PC world, XPS users noticed their machines ran hot and there was a community effort to cool the things down - from different thermal pastes to thermal pads.

--------------------------------------------------------------------------------------------------------------------------------

Srkirt:

I appreciate your efforts to mod the MBA. I am on the cusp or ordering mine and modding the heatsink and your efforts gave me inspiration. I think I'll slip a graphite thermal pad between the CPU and heatsink instead of your red bull can, though.

Even if the thing is cooled, as Max showed with his informal watercooling, the machine has hardcoded limits regardless of if the chip can be pushed further. It'll leave performance on the table. Perhaps it's just ****** binning on apples part.

Got a tip for us?

Let us know

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

2020 Air Heatsink Modification Thread

- Thread starter ilikewhey

- Start date

- Sort by reaction score

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[QUOTE = "ARJR84, publicación: 28371962, miembro: 1213114"]

Hice una cuenta solo por esto.

En primer lugar, el fanboying en este hilo es una tontería. La máquina se calienta claramente para cargas de trabajo reales. Nadie está impresionado de que su máquina funcione a 50 grados mientras realiza una carga de trabajo que su iPhone podría hacer igual de bien. Gracias mods por aclarar algunas de las charlas de ingeniería de la primera mitad del hilo, fue horrible leer de 20 páginas sin que nadie realmente intentara solucionar el problema. En el mundo de las PC, los usuarios de XPS notaron que sus máquinas se calentaban y hubo un esfuerzo de la comunidad para enfriar las cosas, desde diferentes pastas térmicas hasta almohadillas térmicas.

-------------------------------------------------- -------------------------------------------------- ----------------------------

Srkirt:

Agradezco sus esfuerzos para modificar el MBA. Estoy en la cúspide u ordenando el mío y modificando el disipador térmico y sus esfuerzos me inspiraron. Sin embargo, creo que deslizaré una almohadilla térmica de grafito entre la CPU y el disipador térmico en lugar de su lata Red Bull .

.

Incluso si la cosa se enfría, como lo demostró Max con su enfriamiento informal por agua, la máquina tiene límites codificados independientemente de si el chip puede empujarse más. Dejará el rendimiento sobre la mesa. Tal vez es solo una maldita parte de las manzanas.

[MEDIA = youtube] VLKVvpwgGW0 [/ MEDIA]

[/CITAR]

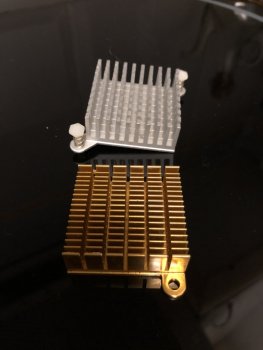

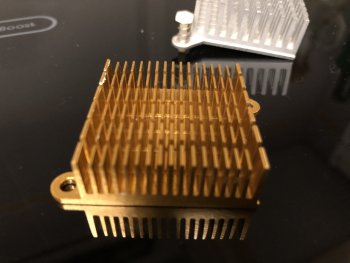

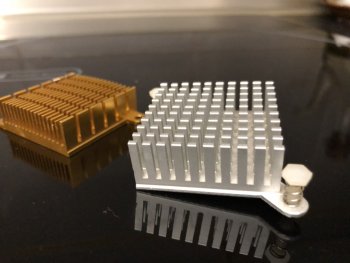

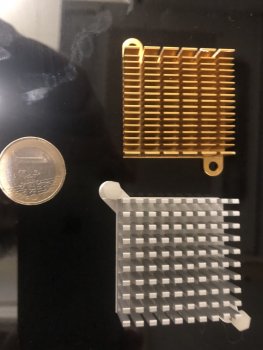

Adapt this type of heatsink if it would be effective ...

Hice una cuenta solo por esto.

En primer lugar, el fanboying en este hilo es una tontería. La máquina se calienta claramente para cargas de trabajo reales. Nadie está impresionado de que su máquina funcione a 50 grados mientras realiza una carga de trabajo que su iPhone podría hacer igual de bien. Gracias mods por aclarar algunas de las charlas de ingeniería de la primera mitad del hilo, fue horrible leer de 20 páginas sin que nadie realmente intentara solucionar el problema. En el mundo de las PC, los usuarios de XPS notaron que sus máquinas se calentaban y hubo un esfuerzo de la comunidad para enfriar las cosas, desde diferentes pastas térmicas hasta almohadillas térmicas.

-------------------------------------------------- -------------------------------------------------- ----------------------------

Srkirt:

Agradezco sus esfuerzos para modificar el MBA. Estoy en la cúspide u ordenando el mío y modificando el disipador térmico y sus esfuerzos me inspiraron. Sin embargo, creo que deslizaré una almohadilla térmica de grafito entre la CPU y el disipador térmico en lugar de su lata Red Bull

Incluso si la cosa se enfría, como lo demostró Max con su enfriamiento informal por agua, la máquina tiene límites codificados independientemente de si el chip puede empujarse más. Dejará el rendimiento sobre la mesa. Tal vez es solo una maldita parte de las manzanas.

[MEDIA = youtube] VLKVvpwgGW0 [/ MEDIA]

[/CITAR]

Adapt this type of heatsink if it would be effective ...

Attachments

Made an account just for this.

First of all, the fanboying in this thread is silly. The machine clearly runs hot for real workloads. Nobody is impressed that your machine runs at 50 degrees while doing a workload your iphone could do just as well. Thank you mods for clearing up some of the engineering talk the first half of the thread, it was horrible reading back and forth for 20 pages without anybody actually trying to fix the problem. In the PC world, XPS users noticed their machines ran hot and there was a community effort to cool the things down - from different thermal pastes to thermal pads.

Dude, the whole reason I bought my first Macbook Air was because I'd come from a Dell XPS M1330. The reason why people were copper modding that PC is because it ran so hot it would burn their legs (it scorched mine), it sounded incredibly loud at all times, and the GPU would burn out.

A mod for the MBA (copper shim, different thermal paste, whatever) would be cool, but it doesn't look like it'd do much more than cool the CPU by a couple of degrees. Nobody I've seen is complaining about case heat, and although it's early days, nobody's having their CPUs melt on them as was common on the XPS.

Again - the XPS M1330 was modded so heavily because it would melt, break and quite literally burn users before 4K tests were even a glint in a YouTuber's eye. That's very different to 'I sometimes hear the fan'.

Dude, the whole reason I bought my first Macbook Air was because I'd come from a Dell XPS M1330. The reason why people were copper modding that PC is because it ran so hot it would burn their legs (it scorched mine), it sounded incredibly loud at all times, and the GPU would burn out.

A mod for the MBA (copper shim, different thermal paste, whatever) would be cool, but it doesn't look like it'd do much more than cool the CPU by a couple of degrees. Nobody I've seen is complaining about case heat, and although it's early days, nobody's having their CPUs melt on them as was common on the XPS.

Again - the XPS M1330 was modded so heavily because it would melt, break and quite literally burn users before 4K tests were even a glint in a YouTuber's eye. That's very different to 'I sometimes hear the fan'.

Ok, but I don't know how I will do it but I plan to take the air to the heatsink even if it is using bronze guitar strings.

Ok, but I don't know how I will do it but I plan to take the air to the heatsink even if it is using bronze guitar strings.

I wish you the best of luck, and I would love to see your before and after results. If it makes the machine better in a meaningful way, that's great! If the results are really great, I may even do it myself. I love experimentation and modding stuff.

My point is, I don't think these mods are needed to stop the machine from destroying itself. That's not even reasonably plausible right now. Most people who buy Macbook Airs aren't enthusiasts who want to crack the case and try and make things better, they want it to just work.

So my point to that other guy comparing the MBA 2020 to the Dell XPS m1330 - where if you didn't mod it, your house would explode - is that it's a bad comparison. Yeah, they're both laptops, but one had a failure rate of 50 percent, a class action lawsuit, and required the user to improve the thermal design to ensure it wouldn't break. There's no indication that that is necessary here.

I wish you the best of luck, and I would love to see your before and after results. If it makes the machine better in a meaningful way, that's great! If the results are really great, I may even do it myself. I love experimentation and modding stuff.

My point is, I don't think these mods are needed to stop the machine from destroying itself. That's not even reasonably plausible right now. Most people who buy Macbook Airs aren't enthusiasts who want to crack the case and try and make things better, they want it to just work.

So my point to that other guy comparing the MBA 2020 to the Dell XPS m1330 - where if you didn't mod it, your house would explode - is that it's a bad comparison. Yeah, they're both laptops, but one had a failure rate of 50 percent, a class action lawsuit, and required the user to improve the thermal design to ensure it wouldn't break. There's no indication that that is necessary here.

I started mounted machine with Intel 386 ... and since then I have always liked overclocking and knowing and finding out the why of things. I am playing with a 3 week € 1,000 Air and I am playing a lot I know, but that makes it even more exciting. We are here in Barcelona confined by the virus and I cannot leave the house, I have to think about doing things with what I have in the basement.

I have many doubts with this Air 2019 and one of them is ventilation ... I still think that the company chose not to refrigerate the machine better because it did not approach the Pro and one way to achieve this was to make the CPU have a high temperature and leave the Turbo Boost works. At 100ºc it is only processing information by 75% !! that's not normal !!! That remaining 25% will never be achieved due to the heat produced inside the machine, I would bet it is. I come from the automotive world and here in Europe it is easier to make a 150HP motor and lower the power with electronics for cheaper versions and get 130hp and 100hp ... My car is like that !! It is the same motor that of 100Cv as that of 150cv !!! Well with the same thing, it is better to cut the power to the high-end processors than to manufacture three different models. I am a stubborn man and I insist that although I have to dissipate the heat through the entire cover, I plan to get 100% of the performance out of the CPU without reaching the maximum temp.

I like your ideas to mod it so keep us updated, I’ve been modding computers and over locking them for a while myself. Hopefully mine arrives soon. I hope you are doing well in Barcelona, I have a lot of family who lives there myself!!I started mounted machine with Intel 386 ... and since then I have always liked overclocking and knowing and finding out the why of things. I am playing with a 3 week € 1,000 Air and I am playing a lot I know, but that makes it even more exciting. We are here in Barcelona confined by the virus and I cannot leave the house, I have to think about doing things with what I have in the basement.

I have many doubts with this Air 2019 and one of them is ventilation ... I still think that the company chose not to refrigerate the machine better because it did not approach the Pro and one way to achieve this was to make the CPU have a high temperature and leave the Turbo Boost works. At 100ºc it is only processing information by 75% !! that's not normal !!! That remaining 25% will never be achieved due to the heat produced inside the machine, I would bet it is. I come from the automotive world and here in Europe it is easier to make a 150HP motor and lower the power with electronics for cheaper versions and get 130hp and 100hp ... My car is like that !! It is the same motor that of 100Cv as that of 150cv !!! Well with the same thing, it is better to cut the power to the high-end processors than to manufacture three different models. I am a stubborn man and I insist that although I have to dissipate the heat through the entire cover, I plan to get 100% of the performance out of the CPU without reaching the maximum temp.

I started mounted machine with Intel 386 ... and since then I have always liked overclocking and knowing and finding out the why of things. I am playing with a 3 week € 1,000 Air and I am playing a lot I know, but that makes it even more exciting. We are here in Barcelona confined by the virus and I cannot leave the house, I have to think about doing things with what I have in the basement.

I have many doubts with this Air 2019 and one of them is ventilation ... I still think that the company chose not to refrigerate the machine better because it did not approach the Pro and one way to achieve this was to make the CPU have a high temperature and leave the Turbo Boost works. At 100ºc it is only processing information by 75% !! that's not normal !!! That remaining 25% will never be achieved due to the heat produced inside the machine, I would bet it is. I

The point is that the chip Apple is using in the Air is intended to be run at lower power. The previous generation was a 7W chip, and it has its roots in the 5W chips that were in the 12" MacBook. This version is 9W, which Apple has custom increased to 10W.

What the enthusiasts, etc. are complaining about is that other manufacturers such as Dell and Acer are using the 15W chips that Apple uses in the base 13" Pro in sub-3 lb. notebooks the same size or smaller than the Air. Apple will use those chips in the next base 13" MacBook Pro, which will likely be at or slightly above 3 lbs. That chip is designed to operate at up to 25W for sustained periods of time, and the MacBook Pro, and presumably the Dell, Acer, etc. have cooling systems designed accordingly.

Does this mean that Apple could have designed the Air to use the 15W chips? Probably. But there would have been some compromises. Dell uses plastic to keep the 13 XPS light, and the base model uses a 1080p screen. It's still a very good notebook, and one I recommend to those looking for a solid Windows notebook. But Apple has made different design decisions. They like using aluminum, which is a bit heavier and requires a different approach to cooling. They chose to use the lower voltage chips. Simply putting in a heat pipe or different fan design isn't going to make those chips run at higher speeds over sustained periods of time. They aren't designed to be run that way.

Bottom line, if you want 13" MacBook Pro performance, get the MacBook Pro!

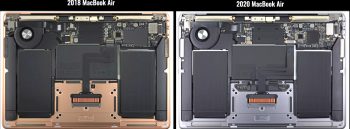

I was shocked at user srkirt's discovery and photos of the massive amount of thermal compound used to fill the cavernous void between the die and heatsink, so I did some experimenting on my 2020 base i3.

First, apologies for my failure to take pics of the process. I cleaned up the die and heatsink with alcohol, the thickness of the layer of thermal paste was insane. As for the heatsink, the portion that lays directly over the die is actually milled out ever so slightly, which increases the gap between the die and the heatsink, madness. I didn't want to use a soda can, as I figured the plastic/paint layer on the outside would affect performance. I ended up using a disposable aluminum foil pan, used for serving food. I cut three layers of foil and sandwiched them together with Noctua NT-H1 thermal paste. I initially tried just two layers, but with two layers and a thin layer of paste on the die, when placing the heatsink on top it didn't fully contact the die, so I added a third layer. With three layers, contact between the heatsink and die was much better, the heatsink would rock back and forth ever so slightly when laid on the die, so with it screwed down it should be making good contact with positive pressure against the die.

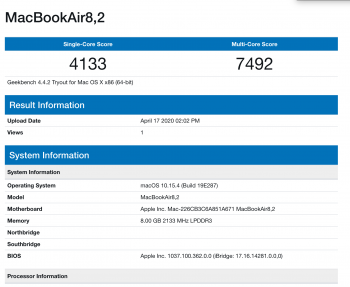

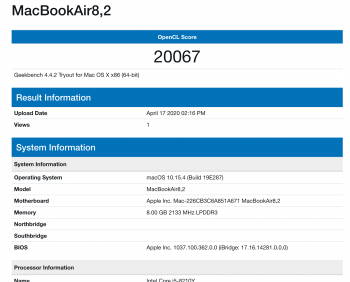

Both before and after the mod, I ran three back-to-back Geekbench CPU tests, followed by a single run of Cinebench. Results speak for themselves in the attached screenshots. The Geekbench shot is taken just after the third run ended, both before and after the mod, and the Cinebench shot shows before and after, again just after the test ended. Both tests show that with better cooling, the CPU is able to run at a higher wattage, and at a higher clock speed in both sustained and burst scenarios. As for the Geekbench scores, I also ran separate sets of 3 tests both pre and post-mod, allowing time to cool off in between. The average multi-core score with stock heatsink was 2145, and with the modded heatsink it was 2309, single-core scores were nearly identical.

My triple-layer foil shim is obviously a crude hack, and having four layers of thermal paste is definitely not ideal. A proper single layer shim, ideally made of copper, and only two layers of paste would probably yield even better cooling/performance. I also think this mod would have an even bigger impact on the i5/i7 CPUs, assuming the heatsinks are of the same garbage design.

Every product design is all about tradeoffs, we in the Apple community are acutely aware of that. However, I fail to see what tradeoff was made in engineering an inadequate cooling system for these MacBook Airs. A tradeoff would be good for bad, positive for negative. Making the heatsink a millimeter thicker would have resulted in better cooling and thus better performance, that's a positive. What I fail to see is the complementary negative to that positive, because there can't possibly be one. Weight, cost, heat, noise, price, none of those would be negatively impacted. Releasing the product as-is, with an inadequate cooling system, is itself a negative, so where's the positive side of the tradeoff? Again, there can't be one.

Apple clearly made a decision with the design of this cooling system. The cynic in me thinks it was for product segmentation purposes, keeping the Air performance below the Pro, and/or keeping it below the performance of the iPad line. Someone please prove me wrong, because I don't want to believe this is the reason.

First, apologies for my failure to take pics of the process. I cleaned up the die and heatsink with alcohol, the thickness of the layer of thermal paste was insane. As for the heatsink, the portion that lays directly over the die is actually milled out ever so slightly, which increases the gap between the die and the heatsink, madness. I didn't want to use a soda can, as I figured the plastic/paint layer on the outside would affect performance. I ended up using a disposable aluminum foil pan, used for serving food. I cut three layers of foil and sandwiched them together with Noctua NT-H1 thermal paste. I initially tried just two layers, but with two layers and a thin layer of paste on the die, when placing the heatsink on top it didn't fully contact the die, so I added a third layer. With three layers, contact between the heatsink and die was much better, the heatsink would rock back and forth ever so slightly when laid on the die, so with it screwed down it should be making good contact with positive pressure against the die.

Both before and after the mod, I ran three back-to-back Geekbench CPU tests, followed by a single run of Cinebench. Results speak for themselves in the attached screenshots. The Geekbench shot is taken just after the third run ended, both before and after the mod, and the Cinebench shot shows before and after, again just after the test ended. Both tests show that with better cooling, the CPU is able to run at a higher wattage, and at a higher clock speed in both sustained and burst scenarios. As for the Geekbench scores, I also ran separate sets of 3 tests both pre and post-mod, allowing time to cool off in between. The average multi-core score with stock heatsink was 2145, and with the modded heatsink it was 2309, single-core scores were nearly identical.

My triple-layer foil shim is obviously a crude hack, and having four layers of thermal paste is definitely not ideal. A proper single layer shim, ideally made of copper, and only two layers of paste would probably yield even better cooling/performance. I also think this mod would have an even bigger impact on the i5/i7 CPUs, assuming the heatsinks are of the same garbage design.

Every product design is all about tradeoffs, we in the Apple community are acutely aware of that. However, I fail to see what tradeoff was made in engineering an inadequate cooling system for these MacBook Airs. A tradeoff would be good for bad, positive for negative. Making the heatsink a millimeter thicker would have resulted in better cooling and thus better performance, that's a positive. What I fail to see is the complementary negative to that positive, because there can't possibly be one. Weight, cost, heat, noise, price, none of those would be negatively impacted. Releasing the product as-is, with an inadequate cooling system, is itself a negative, so where's the positive side of the tradeoff? Again, there can't be one.

Apple clearly made a decision with the design of this cooling system. The cynic in me thinks it was for product segmentation purposes, keeping the Air performance below the Pro, and/or keeping it below the performance of the iPad line. Someone please prove me wrong, because I don't want to believe this is the reason.

Attachments

I was shocked at user srkirt's discovery and photos of the massive amount of thermal compound used to fill the cavernous void between the die and heatsink, so I did some experimenting on my 2020 base i3.

First, apologies for my failure to take pics of the process. I cleaned up the die and heatsink with alcohol, the thickness of the layer of thermal paste was insane. As for the heatsink, the portion that lays directly over the die is actually milled out ever so slightly, which increases the gap between the die and the heatsink, madness. I didn't want to use a soda can, as I figured the plastic/paint layer on the outside would affect performance. I ended up using a disposable aluminum foil pan, used for serving food. I cut three layers of foil and sandwiched them together with Noctua NT-H1 thermal paste. I initially tried just two layers, but with two layers and a thin layer of paste on the die, when placing the heatsink on top it didn't fully contact the die, so I added a third layer. With three layers, contact between the heatsink and die was much better, the heatsink would rock back and forth ever so slightly when laid on the die, so with it screwed down it should be making good contact with positive pressure against the die.

Both before and after the mod, I ran three back-to-back Geekbench CPU tests, followed by a single run of Cinebench. Results speak for themselves in the attached screenshots. The Geekbench shot is taken just after the third run ended, both before and after the mod, and the Cinebench shot shows before and after, again just after the test ended. Both tests show that with better cooling, the CPU is able to run at a higher wattage, and at a higher clock speed in both sustained and burst scenarios. As for the Geekbench scores, I also ran separate sets of 3 tests both pre and post-mod, allowing time to cool off in between. The average multi-core score with stock heatsink was 2145, and with the modded heatsink it was 2309, single-core scores were nearly identical.

My triple-layer foil shim is obviously a crude hack, and having four layers of thermal paste is definitely not ideal. A proper single layer shim, ideally made of copper, and only two layers of paste would probably yield even better cooling/performance. I also think this mod would have an even bigger impact on the i5/i7 CPUs, assuming the heatsinks are of the same garbage design.

Every product design is all about tradeoffs, we in the Apple community are acutely aware of that. However, I fail to see what tradeoff was made in engineering an inadequate cooling system for these MacBook Airs. A tradeoff would be good for bad, positive for negative. Making the heatsink a millimeter thicker would have resulted in better cooling and thus better performance, that's a positive. What I fail to see is the complementary negative to that positive, because there can't possibly be one. Weight, cost, heat, noise, price, none of those would be negatively impacted. Releasing the product as-is, with an inadequate cooling system, is itself a negative, so where's the positive side of the tradeoff? Again, there can't be one.

Apple clearly made a decision with the design of this cooling system. The cynic in me thinks it was for product segmentation purposes, keeping the Air performance below the Pro, and/or keeping it below the performance of the iPad line. Someone please prove me wrong, because I don't want to believe this is the reason.

I think the key thing here is, if people are wanting to do this, get precise measurements of exactly what dimensions a copper shim would need to be to fill this gap, so someone can machine it and see if it works better than homebrewed solutions. Also, photos of the gap wouldn't hurt.

They chose to use the lower voltage chips. Simply putting in a heat pipe or different fan design isn't going to make those chips run at higher speeds over sustained periods of time. They aren't designed to be run that way.

I think the issue for some people such as srkirt is that the CPU hits really high temps even though the package draw is so low, eg 94 degrees at under 9w. This indicates really poor cooling capabilities and just a small change or two could make the Air a whole lot better.

[QUOTE = "Robotronic, publicación: 28373009, miembro: 913214"]

Me sorprendió el descubrimiento del usuario srkirt y las fotos de la gran cantidad de compuesto térmico utilizado para llenar el vacío cavernoso entre el dado y el disipador térmico, así que experimenté un poco en mi base 2020 i3.

Primero, disculpas por no haber tomado fotos del proceso. Limpié el troquel y el disipador térmico con alcohol, el grosor de la capa de pasta térmica era una locura. En cuanto al disipador de calor, la porción que se encuentra directamente sobre el troquel se extrae ligeramente, lo que aumentala brecha entre el dado y el disipador térmico, la locura. No quería usar una lata de refresco, ya que pensé que la capa de plástico / pintura en el exterior afectaría el rendimiento. Terminé usando una bandeja de papel de aluminio desechable, utilizada para servir comida. Corté tres capas de papel de aluminio y las emparedé con pasta térmica Noctua NT-H1. Inicialmente probé solo dos capas, pero con dos capas y una capa delgada de pasta en el troquel, al colocar el disipador de calor en la parte superior no estaba completamente en contacto con el troquel, así que agregué una tercera capa. Con tres capas, el contacto entre el disipador térmico y el troquel era mucho mejor, el disipador térmico se balanceaba ligeramente hacia adelante y hacia atrás muy ligeramente cuando se colocaba sobre el troquel, por lo que con el tornillo atornillado debería estar haciendo buen contacto con presión positiva contra el troquel.

Tanto antes como después del mod, ejecuté tres pruebas consecutivas de CPU Geekbench, seguidas de una sola ejecución de Cinebench. Los resultados hablan por sí mismos en las capturas de pantalla adjuntas. La toma Geekbench se toma justo después de que terminó la tercera carrera, tanto antes como después de la modificación, y la toma Cinebench muestra antes y después, nuevamente justo después de que finalizó la prueba. Ambas pruebas muestran que con una mejor refrigeración, la CPU puede funcionar a una mayor potencia y a una mayor velocidad de reloj tanto en escenarios sostenidos como de ráfaga. En cuanto a los puntajes de Geekbench, también realicé series separadas de 3 pruebas tanto antes como después de la modificación, lo que permitió que el tiempo se enfriara. El puntaje promedio de múltiples núcleos con el disipador térmico estándar fue de 2145, y con el disipador térmico modificado fue de 2309, los puntajes de un solo núcleo fueron casi idénticos.

Mi cuña de aluminio de triple capa es obviamente un truco crudo, y tener cuatro capas de pasta térmica definitivamente no es ideal. Una cuña adecuada de una sola capa, idealmente hecha de cobre, y solo dos capas de pasta probablemente producirían un enfriamiento / rendimiento aún mejor. También creo que este mod tendría un impacto aún mayor en las CPU i5 / i7, suponiendo que los disipadores de calor sean del mismo diseño basura.

Cada diseño de producto tiene que ver con compensaciones, nosotros en la comunidad de Apple somos muy conscientes de eso. Sin embargo, no veo qué compensación se realizó al diseñar un sistema de enfriamiento inadecuado para estos MacBook Airs. Un compromiso sería bueno para malo, positivo para negativo. Hacer que el disipador de calor sea un milímetro más grueso hubiera resultado en un mejor enfriamiento y, por lo tanto, en un mejor rendimiento, eso es positivo. Lo que no veo es el negativo complementario a ese positivo, porque no puede haber uno. Peso, costo, calor, ruido, precio, ninguno de ellos se vería afectado negativamente. Liberar el producto tal cual, con un sistema de enfriamiento inadecuado, es en sí mismo negativo, entonces, ¿dónde está el lado positivo de la compensación? De nuevo, no puede haber uno.

Apple claramente tomó una decisión con el diseño de este sistema de enfriamiento. El cínico en mí piensa que fue para fines de segmentación del producto, manteniendo el rendimiento de Air por debajo del Pro y / o manteniéndolo por debajo del rendimiento de la línea de iPad. Alguien por favor demuestre que estoy equivocado, porque no quiero creer que esta sea la razón.

[/CITAR]. Bravo !!!! Bravo !!!!

[automerge]1587117430[/automerge]

To what you have added the coins ... will dissipate safer.

Me sorprendió el descubrimiento del usuario srkirt y las fotos de la gran cantidad de compuesto térmico utilizado para llenar el vacío cavernoso entre el dado y el disipador térmico, así que experimenté un poco en mi base 2020 i3.

Primero, disculpas por no haber tomado fotos del proceso. Limpié el troquel y el disipador térmico con alcohol, el grosor de la capa de pasta térmica era una locura. En cuanto al disipador de calor, la porción que se encuentra directamente sobre el troquel se extrae ligeramente, lo que aumentala brecha entre el dado y el disipador térmico, la locura. No quería usar una lata de refresco, ya que pensé que la capa de plástico / pintura en el exterior afectaría el rendimiento. Terminé usando una bandeja de papel de aluminio desechable, utilizada para servir comida. Corté tres capas de papel de aluminio y las emparedé con pasta térmica Noctua NT-H1. Inicialmente probé solo dos capas, pero con dos capas y una capa delgada de pasta en el troquel, al colocar el disipador de calor en la parte superior no estaba completamente en contacto con el troquel, así que agregué una tercera capa. Con tres capas, el contacto entre el disipador térmico y el troquel era mucho mejor, el disipador térmico se balanceaba ligeramente hacia adelante y hacia atrás muy ligeramente cuando se colocaba sobre el troquel, por lo que con el tornillo atornillado debería estar haciendo buen contacto con presión positiva contra el troquel.

Tanto antes como después del mod, ejecuté tres pruebas consecutivas de CPU Geekbench, seguidas de una sola ejecución de Cinebench. Los resultados hablan por sí mismos en las capturas de pantalla adjuntas. La toma Geekbench se toma justo después de que terminó la tercera carrera, tanto antes como después de la modificación, y la toma Cinebench muestra antes y después, nuevamente justo después de que finalizó la prueba. Ambas pruebas muestran que con una mejor refrigeración, la CPU puede funcionar a una mayor potencia y a una mayor velocidad de reloj tanto en escenarios sostenidos como de ráfaga. En cuanto a los puntajes de Geekbench, también realicé series separadas de 3 pruebas tanto antes como después de la modificación, lo que permitió que el tiempo se enfriara. El puntaje promedio de múltiples núcleos con el disipador térmico estándar fue de 2145, y con el disipador térmico modificado fue de 2309, los puntajes de un solo núcleo fueron casi idénticos.

Mi cuña de aluminio de triple capa es obviamente un truco crudo, y tener cuatro capas de pasta térmica definitivamente no es ideal. Una cuña adecuada de una sola capa, idealmente hecha de cobre, y solo dos capas de pasta probablemente producirían un enfriamiento / rendimiento aún mejor. También creo que este mod tendría un impacto aún mayor en las CPU i5 / i7, suponiendo que los disipadores de calor sean del mismo diseño basura.

Cada diseño de producto tiene que ver con compensaciones, nosotros en la comunidad de Apple somos muy conscientes de eso. Sin embargo, no veo qué compensación se realizó al diseñar un sistema de enfriamiento inadecuado para estos MacBook Airs. Un compromiso sería bueno para malo, positivo para negativo. Hacer que el disipador de calor sea un milímetro más grueso hubiera resultado en un mejor enfriamiento y, por lo tanto, en un mejor rendimiento, eso es positivo. Lo que no veo es el negativo complementario a ese positivo, porque no puede haber uno. Peso, costo, calor, ruido, precio, ninguno de ellos se vería afectado negativamente. Liberar el producto tal cual, con un sistema de enfriamiento inadecuado, es en sí mismo negativo, entonces, ¿dónde está el lado positivo de la compensación? De nuevo, no puede haber uno.

Apple claramente tomó una decisión con el diseño de este sistema de enfriamiento. El cínico en mí piensa que fue para fines de segmentación del producto, manteniendo el rendimiento de Air por debajo del Pro y / o manteniéndolo por debajo del rendimiento de la línea de iPad. Alguien por favor demuestre que estoy equivocado, porque no quiero creer que esta sea la razón.

[/CITAR]. Bravo !!!! Bravo !!!!

[automerge]1587117430[/automerge]

To what you have added the coins ... will dissipate safer.

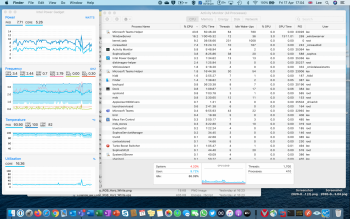

Back to action ... I have obtained an aluminum heatsink fin and I have pushed it away until it is as smooth and flat as possible. I have put pasta in the Intel and then the plate with more pasta. When putting the heatsink you could see that it did not touch the plate, I have put the screws and I have tightened them crosswise, I have not tightened to the end for fear of breaking the cpu. Afterwards I dedicated myself to closing the air tunnel with foam even more and in the end I opted for two coins on top of the cpu so that the air would flow more around it.

[automerge]1587125678[/automerge]

* 1080p no fan.

* 1080p fan, 8.000rpm.

* 2k 60fps no fan.

* 2K 60fps fan, 8.000rpm.

* 4K 60fps no fan.

* 4k 60 fps fan, 8.000rpm.

* reposo no fan.

alimentacion batery 60%.

[automerge]1587125678[/automerge]

* 1080p no fan.

* 1080p fan, 8.000rpm.

* 2k 60fps no fan.

* 2K 60fps fan, 8.000rpm.

* 4K 60fps no fan.

* 4k 60 fps fan, 8.000rpm.

* reposo no fan.

alimentacion batery 60%.

Last edited:

+++10000I was shocked at user srkirt's discovery and photos of the massive amount of thermal compound used to fill the cavernous void between the die and heatsink, so I did some experimenting on my 2020 base i3.

First, apologies for my failure to take pics of the process. I cleaned up the die and heatsink with alcohol, the thickness of the layer of thermal paste was insane. As for the heatsink, the portion that lays directly over the die is actually milled out ever so slightly, which increases the gap between the die and the heatsink, madness. I didn't want to use a soda can, as I figured the plastic/paint layer on the outside would affect performance. I ended up using a disposable aluminum foil pan, used for serving food. I cut three layers of foil and sandwiched them together with Noctua NT-H1 thermal paste. I initially tried just two layers, but with two layers and a thin layer of paste on the die, when placing the heatsink on top it didn't fully contact the die, so I added a third layer. With three layers, contact between the heatsink and die was much better, the heatsink would rock back and forth ever so slightly when laid on the die, so with it screwed down it should be making good contact with positive pressure against the die.

Both before and after the mod, I ran three back-to-back Geekbench CPU tests, followed by a single run of Cinebench. Results speak for themselves in the attached screenshots. The Geekbench shot is taken just after the third run ended, both before and after the mod, and the Cinebench shot shows before and after, again just after the test ended. Both tests show that with better cooling, the CPU is able to run at a higher wattage, and at a higher clock speed in both sustained and burst scenarios. As for the Geekbench scores, I also ran separate sets of 3 tests both pre and post-mod, allowing time to cool off in between. The average multi-core score with stock heatsink was 2145, and with the modded heatsink it was 2309, single-core scores were nearly identical.

My triple-layer foil shim is obviously a crude hack, and having four layers of thermal paste is definitely not ideal. A proper single layer shim, ideally made of copper, and only two layers of paste would probably yield even better cooling/performance. I also think this mod would have an even bigger impact on the i5/i7 CPUs, assuming the heatsinks are of the same garbage design.

Every product design is all about tradeoffs, we in the Apple community are acutely aware of that. However, I fail to see what tradeoff was made in engineering an inadequate cooling system for these MacBook Airs. A tradeoff would be good for bad, positive for negative. Making the heatsink a millimeter thicker would have resulted in better cooling and thus better performance, that's a positive. What I fail to see is the complementary negative to that positive, because there can't possibly be one. Weight, cost, heat, noise, price, none of those would be negatively impacted. Releasing the product as-is, with an inadequate cooling system, is itself a negative, so where's the positive side of the tradeoff? Again, there can't be one.

Apple clearly made a decision with the design of this cooling system. The cynic in me thinks it was for product segmentation purposes, keeping the Air performance below the Pro, and/or keeping it below the performance of the iPad line. Someone please prove me wrong, because I don't want to believe this is the reason.

Your $0.05 hack has given you a much bigger boost in performance than the $150 I paid to go from the i5 to i7 which is basically the same performance after a few seconds as it seems only Geekbench is benefitting from the upgrade. Cinebench multicore went up a measly 6.8% going from i5 to i7, while single core is pathetically the same. Since I’m still waffling on returning my MBA, I’m not ready to try doing a shim, but if another brave i7 buyer would, I think it would allow the chip to stretch its wings....

Hopefully someone can make a third party heatsink that could just be directly replaced with the stock one.

It’ll be more than enough for you. Writing code and pushing it to git or any web server isn’t a CPU-intensive task. You’re not compiling anything.I am a student. I am learning Javascript (Front-End). Will the MBA 2020 (i5 8gb 256ssd) be enough for me? How is the temperature?

In fact, for your use case I’d recommend bumping the RAM to 16GB before bumping the CPU to the i5, unless you’re can afford both. You’ll notice an immediate benefit, especially if you have many tabs open when reading stack overflow, testing your website, have Slack open, etc.

I was shocked at user srkirt's discovery and photos of the massive amount of thermal compound used to fill the cavernous void between the die and heatsink, so I did some experimenting on my 2020 base i3.

First, apologies for my failure to take pics of the process. I cleaned up the die and heatsink with alcohol, the thickness of the layer of thermal paste was insane. As for the heatsink, the portion that lays directly over the die is actually milled out ever so slightly, which increases the gap between the die and the heatsink, madness. I didn't want to use a soda can, as I figured the plastic/paint layer on the outside would affect performance. I ended up using a disposable aluminum foil pan, used for serving food. I cut three layers of foil and sandwiched them together with Noctua NT-H1 thermal paste. I initially tried just two layers, but with two layers and a thin layer of paste on the die, when placing the heatsink on top it didn't fully contact the die, so I added a third layer. With three layers, contact between the heatsink and die was much better, the heatsink would rock back and forth ever so slightly when laid on the die, so with it screwed down it should be making good contact with positive pressure against the die.

Both before and after the mod, I ran three back-to-back Geekbench CPU tests, followed by a single run of Cinebench. Results speak for themselves in the attached screenshots. The Geekbench shot is taken just after the third run ended, both before and after the mod, and the Cinebench shot shows before and after, again just after the test ended. Both tests show that with better cooling, the CPU is able to run at a higher wattage, and at a higher clock speed in both sustained and burst scenarios. As for the Geekbench scores, I also ran separate sets of 3 tests both pre and post-mod, allowing time to cool off in between. The average multi-core score with stock heatsink was 2145, and with the modded heatsink it was 2309, single-core scores were nearly identical.

My triple-layer foil shim is obviously a crude hack, and having four layers of thermal paste is definitely not ideal. A proper single layer shim, ideally made of copper, and only two layers of paste would probably yield even better cooling/performance. I also think this mod would have an even bigger impact on the i5/i7 CPUs, assuming the heatsinks are of the same garbage design.

Every product design is all about tradeoffs, we in the Apple community are acutely aware of that. However, I fail to see what tradeoff was made in engineering an inadequate cooling system for these MacBook Airs. A tradeoff would be good for bad, positive for negative. Making the heatsink a millimeter thicker would have resulted in better cooling and thus better performance, that's a positive. What I fail to see is the complementary negative to that positive, because there can't possibly be one. Weight, cost, heat, noise, price, none of those would be negatively impacted. Releasing the product as-is, with an inadequate cooling system, is itself a negative, so where's the positive side of the tradeoff? Again, there can't be one.

Apple clearly made a decision with the design of this cooling system. The cynic in me thinks it was for product segmentation purposes, keeping the Air performance below the Pro, and/or keeping it below the performance of the iPad line. Someone please prove me wrong, because I don't want to believe this is the reason.

Temp maxi test 74º fan 8.000rpm.

Nice tests! Good to see this small tweak can improve performance overall and let us get more out of the machine.

What about trying something like this https://www.amazon.es/CamKpell-Disi...&sr=8-4&swrs=54B393B35C0ABF644091F86B19532655 (linking amazon.es for srkirt, hi from BCN too

These different hights would allow to get the approx. measure of the gap size.

Thanks for sharing the mods!

As an Amazon Associate, MacRumors earns a commission from qualifying purchases made through links in this post.

Oh boy, I wonder if after all these results we'll still hear the "apple engineers know best" apologists 🙄. They probably do, but they certainly cut corners here. When will they see that their emperor has no clothes? If Ferrari started putting nice big engines inside cheaper car models, but inadequately cooled them, you best believe people will tinker with such cars to squeeze that power that is available but throttled.

I was reading on another forum the poor surface of many macbook's heatsinks. Basically, if they are perfectly flat, which they probably aren't, they have many surface imperfections relative to other heatsinks. A good heatsink will be reflective almost like glass itself. Coupled with poor thermal paste, you get pockets of air and a lot of thermal resistance. They literally took a microscopic image of Apple's poorly made heatsink.

The results here have made me fairly resolute that I'll be either putting a graphite thermal pad between the die and sink or a copper shim with two layers of good paste. Perhaps a thermal pad on top of the sink as well.

Great work, everyone!

I was reading on another forum the poor surface of many macbook's heatsinks. Basically, if they are perfectly flat, which they probably aren't, they have many surface imperfections relative to other heatsinks. A good heatsink will be reflective almost like glass itself. Coupled with poor thermal paste, you get pockets of air and a lot of thermal resistance. They literally took a microscopic image of Apple's poorly made heatsink.

The results here have made me fairly resolute that I'll be either putting a graphite thermal pad between the die and sink or a copper shim with two layers of good paste. Perhaps a thermal pad on top of the sink as well.

Great work, everyone!

Its actually good news to be able to find that flaw with the heatsink. Fixing that issue can be a nice increase in overall performance and temps and may be able to push this laptop even further. A aftermarket heatsink could be ideal but in the meantime the shims could be nice. For the copper shims if you use say 2-3 layers, how do you put those together? Is there a thermal glue you would use to make it one piece and then put thermal paste on both sides wedged between the cooler?Oh boy, I wonder if after all these results we'll still hear the "apple engineers know best" apologists 🙄. They probably do, but they certainly cut corners here. When will they see that their emperor has no clothes? If Ferrari started putting nice big engines inside cheaper car models, but inadequately cooled them, you best believe people will tinker with such cars to squeeze that power that is available but throttled.

I was reading on another forum the poor surface of many macbook's heatsinks. Basically, if they are perfectly flat, which they probably aren't, they have many surface imperfections relative to other heatsinks. A good heatsink will be reflective almost like glass itself. Coupled with poor thermal paste, you get pockets of air and a lot of thermal resistance. They literally took a microscopic image of Apple's poorly made heatsink.

The results here have made me fairly resolute that I'll be either putting a graphite thermal pad between the die and sink or a copper shim with two layers of good paste. Perhaps a thermal pad on top of the sink as well.

Great work, everyone!

I've been using my MBA 2020 I7/16GB/1TB today for work, nothing too strenuous and found the fan on and off with just standard office apps on the go. Close everything down and run an hours team meeting with CPU at around 15% and the temp is 100 deg +- 5 on/off and fans blowing like a hurricane. As much as I like the better performance, this is not really usable long term, the whole chassis is now super hot. Very disappointed and may well look to return in under 24h. I can't ever recall the fan coming on or at least hearing it on my MBA 2018.

Turning off turbo boost does help for a short while but then the temp still rises over 10 mins to the max and CPU is only 15% loaded.

Turning off turbo boost does help for a short while but then the temp still rises over 10 mins to the max and CPU is only 15% loaded.

Attachments

I've been working for a few years designing 3D Printers and in the company there are many factors that could affect these kind of decisions (having a bigger than expected gap CPU-Heatsink, in this case).

- Could be a strategic decision like some suggest, just to keep the macbook air far from pro's performance

- Could also be a 'safe bet' because they haven't had enough time o test a heatsink with less of a gap, and could press too much the CPU bringing out other problems in the long run

- Could be a production line error? Maybe the manufacturer changed a bit the milling process. That's weird but happens.

- Sometimes the cost of a better component increases so much the price of the machine vs the performance improvement that the target client wouldn't even notice, that you just avoid it giving preference to profit margin

- Could be that in the current context with covid etc affected it all. Being cost of the component, testing timings, whatever

- Could be that strategically you need to present this MBA now instead of 3 months later, even if this involves a 90% efficient heatsink, which most clients won't even notice

- Maybe they tested everything and this seemed to be the right choice for overall performance, manufacturing tolerances, cost, availability etc

Basically, there are many many factors that could drive Apple to mount this heatsink. However wouldn't surprise me to have a minor version upgrade of the MBA one-two months from now, completely silent, those that you only see from a slight change in the serial number, that suddenly mounts a better heatsink.

In any case, this kind of mods (inproving heatsink-cpu heat transmission) shouldn't be bad at all, just improving the functionality of already mounted in components. Apart from that I won't go down the road of

- changing the duct shape as it probably allows some heat from the batteries to be released

- uncovering the T2 might be an improvement instead of a failure, but no data no idea here. Won't cover it

- adding heat transmission to the cover (the 2cent coins). First I prefer a cooler case. Second, if the case for any reason bends a bit in the central part would transfer the force directly to the CPU-Motherboard, and that's not ideal at all.

A bit offtopic: After all I'm here waiting for my i5 8gb 256, being sure I'll probably not notice anything of that but will love the keyboard, display, weight, wedge shape, touch ID, premium materials and manufacturing, macOS, and using it for day to day tasks: for me that includes coding python, safari, chrome, spotify, slack, telegram and remote server access. Typing all that from my battle buddy MBP mid 2010 13", with a core2! lol

- Could be a strategic decision like some suggest, just to keep the macbook air far from pro's performance

- Could also be a 'safe bet' because they haven't had enough time o test a heatsink with less of a gap, and could press too much the CPU bringing out other problems in the long run

- Could be a production line error? Maybe the manufacturer changed a bit the milling process. That's weird but happens.

- Sometimes the cost of a better component increases so much the price of the machine vs the performance improvement that the target client wouldn't even notice, that you just avoid it giving preference to profit margin

- Could be that in the current context with covid etc affected it all. Being cost of the component, testing timings, whatever

- Could be that strategically you need to present this MBA now instead of 3 months later, even if this involves a 90% efficient heatsink, which most clients won't even notice

- Maybe they tested everything and this seemed to be the right choice for overall performance, manufacturing tolerances, cost, availability etc

Basically, there are many many factors that could drive Apple to mount this heatsink. However wouldn't surprise me to have a minor version upgrade of the MBA one-two months from now, completely silent, those that you only see from a slight change in the serial number, that suddenly mounts a better heatsink.

In any case, this kind of mods (inproving heatsink-cpu heat transmission) shouldn't be bad at all, just improving the functionality of already mounted in components. Apart from that I won't go down the road of

- changing the duct shape as it probably allows some heat from the batteries to be released

- uncovering the T2 might be an improvement instead of a failure, but no data no idea here. Won't cover it

- adding heat transmission to the cover (the 2cent coins). First I prefer a cooler case. Second, if the case for any reason bends a bit in the central part would transfer the force directly to the CPU-Motherboard, and that's not ideal at all.

A bit offtopic: After all I'm here waiting for my i5 8gb 256, being sure I'll probably not notice anything of that but will love the keyboard, display, weight, wedge shape, touch ID, premium materials and manufacturing, macOS, and using it for day to day tasks: for me that includes coding python, safari, chrome, spotify, slack, telegram and remote server access. Typing all that from my battle buddy MBP mid 2010 13", with a core2! lol

indeed there is thermal glue that both allows heat transfer and sticks both surfaces together. I will just use regular paste rather than glue and rather than multiple shims I"ll just use a thicker one if needed. The pressure itself will prevent the copper from slipping.Its actually good news to be able to find that flaw with the heatsink. Fixing that issue can be a nice increase in overall performance and temps and may be able to push this laptop even further. A aftermarket heatsink could be ideal but in the meantime the shims could be nice. For the copper shims if you use say 2-3 layers, how do you put those together? Is there a thermal glue you would use to make it one piece and then put thermal paste on both sides wedged between the cooler?

I'm confused by this. You've been modding and testing a 2020 model. In the attachments, are the identifiers being misreported as a 2019 model?Temp maxi test 74º fan 8.000rpm.

In example, attached reports say:

"MacBook Air 8,2"

"Memory 8.00 GB 2133 MHz LPDDR3"

Register on MacRumors! This sidebar will go away, and you'll see fewer ads.