Isnt the heatsink a T3? I would get both because if you screw up with T3 you can get it out with a T4.My MBA arrives next week, others have stated:

Pentalobe PL5 screwdriver for bottom of case

Torx T4 for i5 heatsink

Got a tip for us?

Let us know

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

2020 Air Heatsink Modification Thread

- Thread starter ilikewhey

- Start date

- Sort by reaction score

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Isnt the heatsink a T3? I would get both because if you screw up with T3 you can get it out with a T4.

I searched in this thread and found two previous users stating it's a T4. See below.

For my 2020 i7 model:

I bought this iFixit essentials kit: https://www.ifixit.com/Store/Tools/Essential-Electronics-Toolkit/IF145-348?o=2

- Bottom case screws: Pentalobe 5 (P5)

- Heat sink screws: Torx 4 (T4)

Slightly overkill for me because I only needed two of the screwdriver bits 🤣

And:

T4 (Torx 4) for heatsink removal, P5 (Pentalobe 5) for case removal.

Why did you assume it's a T3? Could there be differences between models? I own a 2020 i3

I've spent lots of time on VC over the last few months, Zoom, MS Teams, Webex, Goto Meeting etc. Content seems to drive the temperatures as does the digital backgrounds. Have someone presenting Powerpoint then happy days, have multiple video feeds then the issue starts. Swipe away from the screen so you don't see the feed and balance is replaced. MS teams is the worst for me, Zoom generally ok, limited interaction with others is mixed.Yes agree.

I don't think it is consumer fault too though, because it is normal expectation from consumer to be able to do YT without even reaching 70-80C, normal to expect doing VC / ZOOM without overheat and it is normal for people to expect the new machine should be better (definitely not worse) than previous model which you perfectly mentioned your 2013 model manage to do just fine, so how on earth 2020 model become hotter doing the same thing?

And some people even say 'isn't it between specification to run 70-80C?' YES it is I bet if you look it up at Intel technical specification then the 80C will be in the 'normal'. But anyone with 'common sense' would definitely disagree.

Especially running continuously for hours with that temperature definitely not fine.

My Windows machine is fine with this workload which does make me wonder if this is software issue on MacOS/Driver/Application, I have tried to install bootcamp without success (and I don't need it so I'm not going to wipe my machine for this), but the thing that's niggling in the back of my mind is would Windows natively have the same issue?

Revisiting older hardware, while less capable they are better cooled and with heat pipe, this probably just keep on top of these applications better which seem to generate heat. VC doesn't seem to overly tax the machine i.e. circa 25% CPU load + small amounts of GPU. I agree, going forward shouldn't mean a backward step.

As for long term sustainability at these temperatures, I agree it doesn't seem right but if designed correctly then this should allow the device to operate over its intended life span. I work in Operational Technology, we commonly use hardware that has no moving parts and runs very hot for prolonged periods of time i.e. 5 years + and only passively cooled. While we're on an Intel platform heat is going to be an ongoing issue compounded by ever decreasing thinner designs.

Last edited:

My Windows machine is fine with this workload which does make me wonder if this is software issue on MacOS/Driver/Application, I have tried to install bootcamp without success (and I don't need it so I'm not going to wipe my machine for this), but the thing that's niggling in the back of my mind is would Windows natively have the same issue?

On the MBA 2020, native windows absolutely has the same issues with video conferencing, even without hardware acceleration or virtual backgrounds.

It's the hardware - although Windows is really, really poorly optimised for this generation of Macbook Air

How easy would it be to reverse the thermal paste on top of the heat sink if you need to send your Air for repairs?I'm using copper-shim on-top of the heatsink (not inside, I didn't open the apple heatsink).

The layers:

1. Apple Heatsink

2. Thermal-paste (this is important to make sure the heatsink and copper-shim have proper contact, Im using MX2)

3. Copper-shim (.3mm) (only cover the middle part where the processor is located)

4. Thermal-pad (2mm) (just two stripe of thermal-pad the purpose is to hold the copper-shim so they won't move)

5. Copper-shim (.3mm) (I don't think this one makes much different but I put it anyway as I have plenty of copper-shim and it does get hot when I touch it hence it does transfer away the heat)

My ambient tempt is around 28C

My Geekbench 5:

View attachment 921944

Metal Score:

View attachment 921945

It is paramount to have a proper contact between the heatsink and copper-shim and I have to re-do about 3 to 4 times.

The copper-shim:

Thermal-pad:

IC Chipset GPU CPU Thermal Heatsink Copper Pad Shim Size 20 x 20 x 0.3mm Pack of 20pcs

This Copper Shims thermal conductivity up to 401w / mk, and ordinary copper thermal conductivity is only 20-30w / mk CPU and GPU graphics card in the inside part of the laptop using a thermal plastic thermal conductivity, thermal plastic at high temperature for a long time easy to aging, and...www.amazon.sg

YOUNUON 100x100mm 0.5mm 1mm 1.5mm 2mm 3mm 4mm 5mm tichkess Thermal Pad CPU Heatsink Pad Cooling Conductive Silicone Thermal - AliExpress 7

Smarter Shopping, Better Living! Aliexpress.comwww.aliexpress.com

For anyone who want a much simpler approach would be just to use thermal-pad.

My score with thermal-pad only (no copper shim) in Geekbench multi: ~3400 (single score is about the same)

But if you want to try my approach, below are what I learned:

1. The good contact between heatsink and copper-shim is very important hence the thermal-paste is important factor.

2. If you don't have a good score, redo and make sure the contact between heatsink and copper-shim are good.

The score used here is to shows there is thermal improvement achieved to make the MBA more cool and silent the score is not meant for 'bragging' right that I can make MBA to perform as MBP.

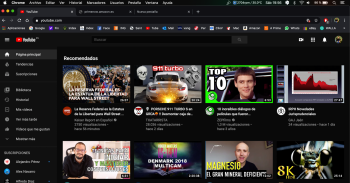

I tried connecting to 2K 32inch external monitor and watch YT 1080p my temp hover around 60-65C better than 70-80C before the mod.

Seeing how a relatively simple and cheap mod can help increase the overall experience of the MBA, I think if APPLE is willing to do this properly it would have been pretty much easy for them.

For me the bottom case screws are Pentalobe 5 (P5) and the heat sink screws are Torx 4 (T4).Isnt the heatsink a T3? I would get both because if you screw up with T3 you can get it out with a T4.

Thanks for the clarification on this @RiaKoobcam, saved me some headache time and confirmed what I hoped wasn't the case. I've seen some other posts which indicate this also happens on the MBP so moving up doesn't resolve this issue either on Apple hardwareOn the MBA 2020, native windows absolutely has the same issues with video conferencing, even without hardware acceleration or virtual backgrounds.

It's the hardware - although Windows is really, really poorly optimised for this generation of Macbook Air

PS just seen your article here, great piece of work: https://forums.macrumors.com/thread...otcamp-so-much-worse-on-the-2020-air.2237998/

Last edited:

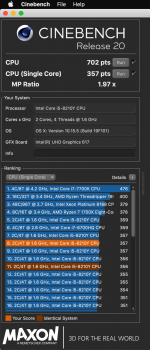

So just added the heatpad mod to my shim mod. My Geekbench score stayed almost the same. Temperature went down. But the temperatures with cinebench are awesome. Score went up to 1140 from 1017, Temperature stays at 85C and fan is not audible. No fan noise whooo and a passive MBA with shim + pad mod.

I measured the case temperatures:

Before heatpad mod 40,7 C after 3 runs fan was audible

After mod 43,1 C after 3 runs fan was NOT audible. After 4 runs of cinebench it went up to 44,6C.

Al in all shim + heatpad mod is the way to go. This machine is now a beast and has lots of performance.

I measured the case temperatures:

Before heatpad mod 40,7 C after 3 runs fan was audible

After mod 43,1 C after 3 runs fan was NOT audible. After 4 runs of cinebench it went up to 44,6C.

Al in all shim + heatpad mod is the way to go. This machine is now a beast and has lots of performance.

Attachments

Last edited:

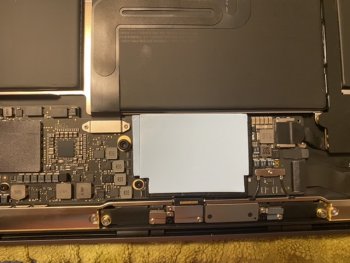

MacBook Air 2020 i5/16GB/256GB heatpipe mod

Background and acknowledgement

Hi guys. Here is a new Air user from Japan. Thanks to all brilliant challengers from this thread (including srkirt, kinchee87, vyruzreaper, RiaKoobcam, Robotronic and DanSilov). I tried the shim mod which is great. The performance is better and more quiet, but the heat dissipation still worries me. I tried the heat pad mod but the bottom is too warm for me and the mod seems to stress the insulating material at the bottom case too much. So, I tried to transfer the heat from the heatsink to the spinning fan without touching the bottom case.

Process

I read this thread for guys who used metal pipe to transfer the heat to somewhere near the fan. I think the improvement is limited because the heat conduction from the metal pipe is not efficient and most air to the fan does not need to pass through the metal pipe. My plan is to make a metal punching mesh to force the spinning fan to cool it.

Here is the overall idea before installation.

I used the remaining 0.3mm copper plate (same as shim mod) to make the copper pipe. And I bought an aluminum punching mesh 0.5mm (I think) because I cannot find a copper mesh on Amazon Japan here.

I used heat insulating double-side adhesive to seal the fan border and brown heat insulating tape to seal the copper plate not to overheat other components. Between the heatsink and copper pipe I used a heated (0.5mm, 6mW only) to hold the pipe in place. On top I used the brown heat insulating tape again to ensure no contact and heating up of bottom case.

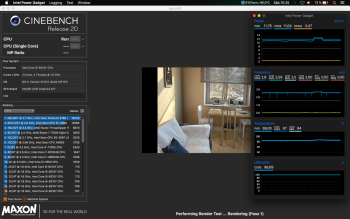

Results

I found that the startup CPU temperature with shim mod alone still reaches 100 degree. But with heated mod it was 70 degree. This one is 80 degree but the temperature drops very quickly with fan spinning. I used TG Pro to setup a custom profile (4500 rpm always and maximum 7000 rpm over 90 degree).

I ran Geekbench Multicore CPU test and found that the score is very good

3169 (shim mod)

3595 (shim + heatpipe mod)

The heat profile also proves that heat is transferred properly. The frequency (light blue) during early low utilization part of the test caught up the requested one (pink) than shim pad alone. And heavy load part is better also (though heatpad mod is better because the heatpipe and fan speed capacity). You can find the comparison quoted from DanSilov thread below.

Conclusion

I am very happy to have this little reversible fix to help my Air performing better. I don't want the touch bar, and this mod helps me to have a comfortable use of my Air for years (at least I think). Thank you all.

Background and acknowledgement

Hi guys. Here is a new Air user from Japan. Thanks to all brilliant challengers from this thread (including srkirt, kinchee87, vyruzreaper, RiaKoobcam, Robotronic and DanSilov). I tried the shim mod which is great. The performance is better and more quiet, but the heat dissipation still worries me. I tried the heat pad mod but the bottom is too warm for me and the mod seems to stress the insulating material at the bottom case too much. So, I tried to transfer the heat from the heatsink to the spinning fan without touching the bottom case.

Process

I read this thread for guys who used metal pipe to transfer the heat to somewhere near the fan. I think the improvement is limited because the heat conduction from the metal pipe is not efficient and most air to the fan does not need to pass through the metal pipe. My plan is to make a metal punching mesh to force the spinning fan to cool it.

Here is the overall idea before installation.

I used the remaining 0.3mm copper plate (same as shim mod) to make the copper pipe. And I bought an aluminum punching mesh 0.5mm (I think) because I cannot find a copper mesh on Amazon Japan here.

I used heat insulating double-side adhesive to seal the fan border and brown heat insulating tape to seal the copper plate not to overheat other components. Between the heatsink and copper pipe I used a heated (0.5mm, 6mW only) to hold the pipe in place. On top I used the brown heat insulating tape again to ensure no contact and heating up of bottom case.

Results

I found that the startup CPU temperature with shim mod alone still reaches 100 degree. But with heated mod it was 70 degree. This one is 80 degree but the temperature drops very quickly with fan spinning. I used TG Pro to setup a custom profile (4500 rpm always and maximum 7000 rpm over 90 degree).

I ran Geekbench Multicore CPU test and found that the score is very good

3169 (shim mod)

3595 (shim + heatpipe mod)

The heat profile also proves that heat is transferred properly. The frequency (light blue) during early low utilization part of the test caught up the requested one (pink) than shim pad alone. And heavy load part is better also (though heatpad mod is better because the heatpipe and fan speed capacity). You can find the comparison quoted from DanSilov thread below.

Conclusion

I am very happy to have this little reversible fix to help my Air performing better. I don't want the touch bar, and this mod helps me to have a comfortable use of my Air for years (at least I think). Thank you all.

Last edited:

I'm using copper-shim on-top of the heatsink (not inside, I didn't open the apple heatsink).

The layers:

1. Apple Heatsink

2. Thermal-paste (this is important to make sure the heatsink and copper-shim have proper contact, Im using MX2)

3. Copper-shim (.3mm) (only cover the middle part where the processor is located)

4. Thermal-pad (2mm) (just two stripe of thermal-pad the purpose is to hold the copper-shim so they won't move)

5. Copper-shim (.3mm) (I don't think this one makes much different but I put it anyway as I have plenty of copper-shim and it does get hot when I touch it hence it does transfer away the heat)

My ambient tempt is around 28C

My Geekbench 5:

View attachment 921944

Metal Score:

View attachment 921945

It is paramount to have a proper contact between the heatsink and copper-shim and I have to re-do about 3 to 4 times.

The copper-shim:

Thermal-pad:

IC Chipset GPU CPU Thermal Heatsink Copper Pad Shim Size 20 x 20 x 0.3mm Pack of 20pcs

This Copper Shims thermal conductivity up to 401w / mk, and ordinary copper thermal conductivity is only 20-30w / mk CPU and GPU graphics card in the inside part of the laptop using a thermal plastic thermal conductivity, thermal plastic at high temperature for a long time easy to aging, and...www.amazon.sg

YOUNUON 100x100mm 0.5mm 1mm 1.5mm 2mm 3mm 4mm 5mm tichkess Thermal Pad CPU Heatsink Pad Cooling Conductive Silicone Thermal - AliExpress 7

Smarter Shopping, Better Living! Aliexpress.comwww.aliexpress.com

For anyone who want a much simpler approach would be just to use thermal-pad.

My score with thermal-pad only (no copper shim) in Geekbench multi: ~3400 (single score is about the same)

But if you want to try my approach, below are what I learned:

1. The good contact between heatsink and copper-shim is very important hence the thermal-paste is important factor.

2. If you don't have a good score, redo and make sure the contact between heatsink and copper-shim are good.

The score used here is to shows there is thermal improvement achieved to make the MBA more cool and silent the score is not meant for 'bragging' right that I can make MBA to perform as MBP.

I tried connecting to 2K 32inch external monitor and watch YT 1080p my temp hover around 60-65C better than 70-80C before the mod.

Seeing how a relatively simple and cheap mod can help increase the overall experience of the MBA, I think if APPLE is willing to do this properly it would have been pretty much easy for them.

That configuration is not correct and I am telling you that I have done more tests than anyone else in this forum ... the most effective way is: on top of the thermal paste and the two sanded and clean copper sheets with glass ceramic paste and isopropyl alcohol , including more paste and the sink also sanded and well cleaned with more paste. No pads that being so thick loses dissipation power ... they are not designed for cpu or gpu but rather for memories or chips. If later you want to put the pad on the heatsink yourself, but inside the cpu only paste and in this case, less is more ... do not put too much because it is counterproductive. Listen to me or ask in the forum and you will see the things I have come to do and have in a 2019 i5 the power of an i7. Sealing the wind tunnel is as important as removing heat from the cpu ...

[automerge]1591444843[/automerge]

Bravo !!! I will test it soldered to my copper radiator.MacBook Air 2020 i5/16GB/256GB heatpipe mod

Background and acknowledgement

Hi guys. Here is a new Air user from Japan. Thanks to all brilliant challengers from this thread (including srkirt, kinchee87, vyruzreaper, RiaKoobcam, Robotronic and DanSilov). I tried the shim mod which is great. The performance is better and more quiet, but the heat dissipation still worries me. I tried the heat pad mod but the bottom is too warm for me and the mod seems to stress the insulating material at the bottom case too much. So, I tried to transfer the heat from the heatsink to the spinning fan without touching the bottom case.

Process

I read this thread for guys who used metal pipe to transfer the heat to somewhere near the fan. I think the improvement is limited because the heat conduction from the metal pipe is not efficient and most air to the fan does not need to pass through the metal pipe. My plan is to make a metal punching mesh to force the spinning fan to cool it.

Here is the overall idea before installation.

View attachment 921971

I used the remaining 0.3mm copper plate (same as shim mod) to make the copper pipe. And I bought an aluminum punching mesh 0.5mm (I think) because I cannot find a copper mesh on Amazon Japan here.

View attachment 921973View attachment 921974

I used heat insulating double-side adhesive to seal the fan border and brown heat insulating tape to seal the copper plate not to overheat other components. Between the heatsink and copper pipe I used a heated (0.5mm, 6mW only) to hold the pipe in place. On top I used the brown heat insulating tape again to ensure no contact and heating up of bottom case.

Results

I found that the startup CPU temperature with shim mod alone still reaches 100 degree. But with heated mod it was 70 degree. This one is 80 degree but the temperature drops very quickly with fan spinning. I used TG Pro to setup a custom profile (4500 rpm always and maximum 7000 rpm over 90 degree).

I ran Geekbench Multicore CPU test and found that the score is very good

3169 (shim mod)

3595 (shim + heatpipe mod)

View attachment 921976

The heat profile also proves that heat is transferred properly. The frequency (light blue) during early low utilization part of the test caught up the requested one (pink) than shim pad alone. And heavy load part is better also (though heatpad mod is better because the heatpipe and fan speed capacity). You can find the comparison quoted from DanSilov thread below.

View attachment 921978

Conclusion

I am very happy to have this little reversible fix to help my Air performing better. I don't want the touch bar, and this mod helps me to have a comfortable use of my Air for years (at least I think).

Disclaimer

This mod is based on the results from all community members and I posted here to feedback in return. Please try and tell me what do you feel. I think this is a community input and please DO NOT USE THIS FOR COMMERCIAL PURPOSE. Thank you.

Attachments

Last edited:

That configuration is not correct and I am telling you that I have done more tests than anyone else in this forum ... the most effective way is: on top of the thermal paste and the two sanded and clean copper sheets with glass ceramic paste and isopropyl alcohol , including more paste and the sink also sanded and well cleaned with more paste. No pads that being so thick loses dissipation power ... they are not designed for cpu or gpu but rather for memories or chips. If later you want to put the pad on the heatsink yourself, but inside the cpu only paste and in this case, less is more ... do not put too much because it is counterproductive. Listen to me or ask in the forum and you will see the things I have come to do and have in a 2019 i5 the power of an i7. Sealing the wind tunnel is as important as removing heat from the cpu ...

[automerge]1591444843[/automerge]

Bravo !!! I will test it soldered to my copper radiator.

Hi srkirt,

I also thought about soldering. It seems tin has an excellent electrical conductivity but much moderate heat conductivity. Of cause tin is better than heatpad (which usually 6-12 W/mK).

Btw, copper and aluminium alloys are roughly 400W/mK and 150W/mK respectivity.

@IngerMan in fact by starting at 31º idle the results are way better that before. But still far from 4000 multi-core score. Strange!How can my multi-core score be only ~3500, with same thermal pad you have and recently updated to Catalina .5?

Attachments

MacBook Air 2020 i5/16GB/256GB heatpipe mod

Background and acknowledgement

Hi guys. Here is a new Air user from Japan. Thanks to all brilliant challengers from this thread (including srkirt, kinchee87, vyruzreaper, RiaKoobcam, Robotronic and DanSilov). I tried the shim mod which is great. The performance is better and more quiet, but the heat dissipation still worries me. I tried the heat pad mod but the bottom is too warm for me and the mod seems to stress the insulating material at the bottom case too much. So, I tried to transfer the heat from the heatsink to the spinning fan without touching the bottom case.

Process

I read this thread for guys who used metal pipe to transfer the heat to somewhere near the fan. I think the improvement is limited because the heat conduction from the metal pipe is not efficient and most air to the fan does not need to pass through the metal pipe. My plan is to make a metal punching mesh to force the spinning fan to cool it.

Here is the overall idea before installation.

View attachment 921971

I used the remaining 0.3mm copper plate (same as shim mod) to make the copper pipe. And I bought an aluminum punching mesh 0.5mm (I think) because I cannot find a copper mesh on Amazon Japan here.

View attachment 921973View attachment 921974

I used heat insulating double-side adhesive to seal the fan border and brown heat insulating tape to seal the copper plate not to overheat other components. Between the heatsink and copper pipe I used a heated (0.5mm, 6mW only) to hold the pipe in place. On top I used the brown heat insulating tape again to ensure no contact and heating up of bottom case.

Results

I found that the startup CPU temperature with shim mod alone still reaches 100 degree. But with heated mod it was 70 degree. This one is 80 degree but the temperature drops very quickly with fan spinning. I used TG Pro to setup a custom profile (4500 rpm always and maximum 7000 rpm over 90 degree).

I ran Geekbench Multicore CPU test and found that the score is very good

3169 (shim mod)

3595 (shim + heatpipe mod)

View attachment 921976

The heat profile also proves that heat is transferred properly. The frequency (light blue) during early low utilization part of the test caught up the requested one (pink) than shim pad alone. And heavy load part is better also (though heatpad mod is better because the heatpipe and fan speed capacity). You can find the comparison quoted from DanSilov thread below.

View attachment 921978

Conclusion

I am very happy to have this little reversible fix to help my Air performing better. I don't want the touch bar, and this mod helps me to have a comfortable use of my Air for years (at least I think).

Disclaimer

This mod is based on the results from all community members and I posted here to feedback in return. Please try and tell me what do you feel. I think this is a community input and please DO NOT USE THIS FOR COMMERCIAL PURPOSE. Thank you.

Holy crap dude, next level. Great work! お疲れ様でした !!!

[QUOTE = "kazune_karin, publicación: 28537448, miembro: 1216360"]

Hola srkirt

También pensé en soldar. Parece que el estaño tiene una excelente conductividad eléctrica pero mucha conductividad térmica moderada. Por causa, el estaño es mejor que la almohadilla térmica (que generalmente es de 6-12 W / mK).

Por cierto, las aleaciones de cobre y aluminio tienen aproximadamente 400W / mK y 150W / mK de respeto.

[/CITAR]

Look my records are already above an i7 ... I am going to try doing it, I will use the mesh of a kitchen strainer because I see too much sheet and must restrict the air flow for memory etc etc. I also make a mini copper radiator. Ideally, the copper strip is on top of the processor and the heatsink is screwed just to hold it, then if all the heat from the CPU goes to the fan ... I think ...

Hola srkirt

También pensé en soldar. Parece que el estaño tiene una excelente conductividad eléctrica pero mucha conductividad térmica moderada. Por causa, el estaño es mejor que la almohadilla térmica (que generalmente es de 6-12 W / mK).

Por cierto, las aleaciones de cobre y aluminio tienen aproximadamente 400W / mK y 150W / mK de respeto.

[/CITAR]

Look my records are already above an i7 ... I am going to try doing it, I will use the mesh of a kitchen strainer because I see too much sheet and must restrict the air flow for memory etc etc. I also make a mini copper radiator. Ideally, the copper strip is on top of the processor and the heatsink is screwed just to hold it, then if all the heat from the CPU goes to the fan ... I think ...

Attachments

[QUOTE = "kazune_karin, publicación: 28537448, miembro: 1216360"]

Hola srkirt

También pensé en soldar. Parece que el estaño tiene una excelente conductividad eléctrica pero mucha conductividad térmica moderada. Por causa, el estaño es mejor que la almohadilla térmica (que generalmente es de 6-12 W / mK).

Por cierto, las aleaciones de cobre y aluminio tienen aproximadamente 400W / mK y 150W / mK de respeto.

[/CITAR]

Look my records are already above an i7 ... I am going to try doing it, I will use the mesh of a kitchen strainer because I see too much sheet and must restrict the air flow for memory etc etc. I also make a mini copper radiator. Ideally, the copper strip is on top of the processor and the heatsink is screwed just to hold it, then if all the heat from the CPU goes to the fan ... I think ...

Makes sence. Looking forward to your results!

T4 didnt fit well but T3 did so it depends. I think with enough pressure T4 will fit. Now T4 fits my screws after several trysI searched in this thread and found two previous users stating it's a T4. See below.

And:

Why did you assume it's a T3? Could there be differences between models? I own a 2020 i3

I have several questions about air movement in the 2020 MBA, several experts here

1) would “sealing the wind tunnel” cause increased heat at the trackpad + batteries due to less air movement in that section? Issues with increased battery temps?

2) Does the pad mod work so well because, in addition to transferring heat directly to the large aluminum case bottom, it blocks air passage over the top of the heat sink, theoretically causing increased air motion (velocity and volume) through the sink itself. Which may be why it works well, even leaving the stock heat protection padding on the case bottom.

3) I seem to remember someone using strips of thermal pad, instead of solid coverage. I would be interested in an experiment. Using a 10mm strip of thermal padding only, compare the strip running in the middle of the seat sink first along the air flow (heat transfer to case only) vs. strip across the heat flow (blocking air flow over top of heat sink)

4) has anyone padded the other hot parts on the motherboard? (voltage regulators, etc)

I guess I’m wondering how important limiting the air tunnel cross section is, by improving airflow through the heat sink. Of course this would only work when the fan is active. To keep the fan from running, the larger the ambient space, with non-fan air motion, the better.

I also wonder about a certain ratio of heat transfer to the case balancing CPU cooling and lap comfort. I would find a good compromise of running simpler apps, MS Word, Chrome, with acceptable on lap temps. I could live with running higher under case thermals on more demanding applications (Zoom, video), while running on a desk/table top.

With that thought, I want to selectively apply a certain amount of padding, in the best configuration to maximize heat transfer to both air and case bottom. I think the heat transfer ratio to the case can be adjusted by square cm of padding used. Blocking the air flow on top of heat sink has some advantages, when the fan is running, but may be detrimental when the fan is not.

1) would “sealing the wind tunnel” cause increased heat at the trackpad + batteries due to less air movement in that section? Issues with increased battery temps?

2) Does the pad mod work so well because, in addition to transferring heat directly to the large aluminum case bottom, it blocks air passage over the top of the heat sink, theoretically causing increased air motion (velocity and volume) through the sink itself. Which may be why it works well, even leaving the stock heat protection padding on the case bottom.

3) I seem to remember someone using strips of thermal pad, instead of solid coverage. I would be interested in an experiment. Using a 10mm strip of thermal padding only, compare the strip running in the middle of the seat sink first along the air flow (heat transfer to case only) vs. strip across the heat flow (blocking air flow over top of heat sink)

4) has anyone padded the other hot parts on the motherboard? (voltage regulators, etc)

I guess I’m wondering how important limiting the air tunnel cross section is, by improving airflow through the heat sink. Of course this would only work when the fan is active. To keep the fan from running, the larger the ambient space, with non-fan air motion, the better.

I also wonder about a certain ratio of heat transfer to the case balancing CPU cooling and lap comfort. I would find a good compromise of running simpler apps, MS Word, Chrome, with acceptable on lap temps. I could live with running higher under case thermals on more demanding applications (Zoom, video), while running on a desk/table top.

With that thought, I want to selectively apply a certain amount of padding, in the best configuration to maximize heat transfer to both air and case bottom. I think the heat transfer ratio to the case can be adjusted by square cm of padding used. Blocking the air flow on top of heat sink has some advantages, when the fan is running, but may be detrimental when the fan is not.

My opinion...I have several questions about air movement in the 2020 MBA, several experts here

1) would “sealing the wind tunnel” cause increased heat at the trackpad + batteries due to less air movement in that section? Issues with increased battery temps?

2) Does the pad mod work so well because, in addition to transferring heat directly to the large aluminum case bottom, it blocks air passage over the top of the heat sink, theoretically causing increased air motion (velocity and volume) through the sink itself. Which may be why it works well, even leaving the stock heat protection padding on the case bottom.

3) I seem to remember someone using strips of thermal pad, instead of solid coverage. I would be interested in an experiment. Using a 10mm strip of thermal padding only, compare the strip running in the middle of the seat sink first along the air flow (heat transfer to case only) vs. strip across the heat flow (blocking air flow over top of heat sink)

4) has anyone padded the other hot parts on the motherboard? (voltage regulators, etc)

I guess I’m wondering how important limiting the air tunnel cross section is, by improving airflow through the heat sink. Of course this would only work when the fan is active. To keep the fan from running, the larger the ambient space, with non-fan air motion, the better.

I also wonder about a certain ratio of heat transfer to the case balancing CPU cooling and lap comfort. I would find a good compromise of running simpler apps, MS Word, Chrome, with acceptable on lap temps. I could live with running higher under case thermals on more demanding applications (Zoom, video), while running on a desk/table top.

With that thought, I want to selectively apply a certain amount of padding, in the best configuration to maximize heat transfer to both air and case bottom. I think the heat transfer ratio to the case can be adjusted by square cm of padding used. Blocking the air flow on top of heat sink has some advantages, when the fan is running, but may be detrimental when the fan is not.

sealing the wind tunnel is much better as long as you have a breeze at around 2000rpm with the Macs Fan Control than at those rpm you don't even hear and thus protect the other components. I prefer that to having everything open and cool by convection ... nothing happens to the batteries (I have tried everything) is more, today between the heatsink and the batteries there is a piece of metal, because I have communicated with putty the heatsink with that metal to radiate through the chassis. By the cover I have tried everything of everything! and all I have done is turn the pc into an oven in my belly ... try to isolate it even with gorilla glass and it transferred the heat. The thermal paste does not convince me ... I have put memory and T2 but it would be interesting to put the ssd behind. You just have to prove that when you seal the enclosure and turn on the fan at 8,000rpm you notice how the air draft comes out despite having a very small inlet and outlet.

Tip: always have a 2,200 or 2,500rpm to have a breeze to all the components, both the ones you see and the ones you don't see and are above the keyboard.

With Cinebench I always have a stable temp and therefore, being between 82 / 86º, the turbo boost does not disconnect, this is due to good dissipation towards the radiator and good expulsion of hot air out of the housing.

Attachments

Thanks @srkirt ! The concept of the always on fan will allay a lot of my misgivings about the passive heat dissipation.

I’m set on repasting with a shim, I will probably start with small pad, and enlarge as possible to keep the bottom from getting too hot during the simpler use profiles. Perhaps sequentially blocking airflow over the top of the heat sink.

I’m set on repasting with a shim, I will probably start with small pad, and enlarge as possible to keep the bottom from getting too hot during the simpler use profiles. Perhaps sequentially blocking airflow over the top of the heat sink.

Your idea is fantastic and a big step, enough to hit Tim in the face with the invention. I have pending of Ali that arrives me a copper dissipater to which I could adapt, anyway I already have a plate with the measure of the radiator and its 4 holes, alone it would be to put the wedge in the cpu and in the copper plate to weld a strip up to the fan. As I don't have fins, it would radiate a lot of heat but it would go through the piece of soldered material to the fan. Once there and protected by adhesive tape that holds up to 100º the fan grill or I would do it with fine copper strips or I would try with a kitchen strainer if it can be tinned... what a mess you have put me in... take directly from the top of the cpu to the fan... piece of cannon!MacBook Air 2020 i5/16GB/256GB heatpipe mod

We need your help to keep this non-profit!

To help battling against commercial usage and keep this as a non-profit community input, if you adapt this mod, please DO NOT SHARE ANY MESAUREMENTS regarding any componenets. This will keep out pure opportunists because they will have to buy themselves a MacBook before doing commercialization.

Background and acknowledgement

Hi guys. Here is a new Air user from Japan. Thanks to all brilliant challengers from this thread (including srkirt, kinchee87, vyruzreaper, RiaKoobcam, Robotronic and DanSilov). I tried the shim mod which is great. The performance is better and more quiet, but the heat dissipation still worries me. I tried the heat pad mod but the bottom is too warm for me and the mod seems to stress the insulating material at the bottom case too much. So, I tried to transfer the heat from the heatsink to the spinning fan without touching the bottom case.

Process

I read this thread for guys who used metal pipe to transfer the heat to somewhere near the fan. I think the improvement is limited because the heat conduction from the metal pipe is not efficient and most air to the fan does not need to pass through the metal pipe. My plan is to make a metal punching mesh to force the spinning fan to cool it.

Here is the overall idea before installation.

View attachment 921971

I used the remaining 0.3mm copper plate (same as shim mod) to make the copper pipe. And I bought an aluminum punching mesh 0.5mm (I think) because I cannot find a copper mesh on Amazon Japan here.

View attachment 921973View attachment 921974

I used heat insulating double-side adhesive to seal the fan border and brown heat insulating tape to seal the copper plate not to overheat other components. Between the heatsink and copper pipe I used a heated (0.5mm, 6mW only) to hold the pipe in place. On top I used the brown heat insulating tape again to ensure no contact and heating up of bottom case.

Results

I found that the startup CPU temperature with shim mod alone still reaches 100 degree. But with heated mod it was 70 degree. This one is 80 degree but the temperature drops very quickly with fan spinning. I used TG Pro to setup a custom profile (4500 rpm always and maximum 7000 rpm over 90 degree).

I ran Geekbench Multicore CPU test and found that the score is very good

3169 (shim mod)

3595 (shim + heatpipe mod)

View attachment 921976

The heat profile also proves that heat is transferred properly. The frequency (light blue) during early low utilization part of the test caught up the requested one (pink) than shim pad alone. And heavy load part is better also (though heatpad mod is better because the heatpipe and fan speed capacity). You can find the comparison quoted from DanSilov thread below.

View attachment 921978

Conclusion

I am very happy to have this little reversible fix to help my Air performing better. I don't want the touch bar, and this mod helps me to have a comfortable use of my Air for years (at least I think). Thank you all.

Desktop at rest, see what temp ...Thanks @srkirt ! The concept of the always on fan will allay a lot of my misgivings about the passive heat dissipation.

I’m set on repasting with a shim, I will probably start with small pad, and enlarge as possible to keep the bottom from getting too hot during the simpler use profiles. Perhaps sequentially blocking airflow over the top of the heat sink.

Attachments

It’s definitely a T3. At least this is what works on 2020 MBA i5. So P5 (1.2) and T3T4 didnt fit well but T3 did so it depends. I think with enough pressure T4 will fit. Now T4 fits my screws after several trys.

hey do you mind if i put this in 1st page post?MacBook Air 2020 i5/16GB/256GB heatpipe mod

We need your help to keep this non-profit!

To help battling against commercial usage and keep this as a non-profit community input, if you adapt this mod, please DO NOT SHARE ANY MESAUREMENTS regarding any componenets. This will keep out pure opportunists because they will have to buy themselves a MacBook before doing commercialization.

Background and acknowledgement

Hi guys. Here is a new Air user from Japan. Thanks to all brilliant challengers from this thread (including srkirt, kinchee87, vyruzreaper, RiaKoobcam, Robotronic and DanSilov). I tried the shim mod which is great. The performance is better and more quiet, but the heat dissipation still worries me. I tried the heat pad mod but the bottom is too warm for me and the mod seems to stress the insulating material at the bottom case too much. So, I tried to transfer the heat from the heatsink to the spinning fan without touching the bottom case.

Process

I read this thread for guys who used metal pipe to transfer the heat to somewhere near the fan. I think the improvement is limited because the heat conduction from the metal pipe is not efficient and most air to the fan does not need to pass through the metal pipe. My plan is to make a metal punching mesh to force the spinning fan to cool it.

Here is the overall idea before installation.

View attachment 921971

I used the remaining 0.3mm copper plate (same as shim mod) to make the copper pipe. And I bought an aluminum punching mesh 0.5mm (I think) because I cannot find a copper mesh on Amazon Japan here.

View attachment 921973View attachment 921974

I used heat insulating double-side adhesive to seal the fan border and brown heat insulating tape to seal the copper plate not to overheat other components. Between the heatsink and copper pipe I used a heated (0.5mm, 6mW only) to hold the pipe in place. On top I used the brown heat insulating tape again to ensure no contact and heating up of bottom case.

Results

I found that the startup CPU temperature with shim mod alone still reaches 100 degree. But with heated mod it was 70 degree. This one is 80 degree but the temperature drops very quickly with fan spinning. I used TG Pro to setup a custom profile (4500 rpm always and maximum 7000 rpm over 90 degree).

I ran Geekbench Multicore CPU test and found that the score is very good

3169 (shim mod)

3595 (shim + heatpipe mod)

View attachment 921976

The heat profile also proves that heat is transferred properly. The frequency (light blue) during early low utilization part of the test caught up the requested one (pink) than shim pad alone. And heavy load part is better also (though heatpad mod is better because the heatpipe and fan speed capacity). You can find the comparison quoted from DanSilov thread below.

View attachment 921978

Conclusion

I am very happy to have this little reversible fix to help my Air performing better. I don't want the touch bar, and this mod helps me to have a comfortable use of my Air for years (at least I think). Thank you all.

hey do you mind if i put this in 1st page post?

Hi ilikewhey,

I am fine with that. It would be grateful if you only select one photo and leave other as a link to the original thread. So all other pioneering mods will be honoured also.

[automerge]1591521455[/automerge]

Your idea is fantastic and a big step, enough to hit Tim in the face with the invention. I have pending of Ali that arrives me a copper dissipater to which I could adapt, anyway I already have a plate with the measure of the radiator and its 4 holes, alone it would be to put the wedge in the cpu and in the copper plate to weld a strip up to the fan. As I don't have fins, it would radiate a lot of heat but it would go through the piece of soldered material to the fan. Once there and protected by adhesive tape that holds up to 100º the fan grill or I would do it with fine copper strips or I would try with a kitchen strainer if it can be tinned... what a mess you have put me in... take directly from the top of the cpu to the fan... piece of cannon!

Thanks. My max score is close to base 2020 MBP, so I am satisfied. Just curious if a i7 Air 2020 can compete with i5 10th gen Pro 2020 (Dream.

I can use my device safetly without heat concern. If I become itcy again, I may try your wind tunnel mod as well. Do you think it will be beneficial also?

So, I did the mod today. I am not sure I applied paste correctly. I used Noctua NT-H2 for now. Anyone care to comment on how to apply paste correctly?

Register on MacRumors! This sidebar will go away, and you'll see fewer ads.