No tray drilling required, correct?I recently switched from plastic to metal-based retention and recommend this kit - https://www.ebay.com/itm/Mac-Pro-4-...e=STRK:MEBIDX:IT&_trksid=p2060353.m2749.l2649

Got a tip for us?

Let us know

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

clip (snap rivet) for Northbridge heat-sink on 2009 Mac Pro 2X2.26

- Thread starter i-rui

- Start date

- Sort by reaction score

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

No tray drilling required, correct?

Drilling? Absolutely not. The kit's pack comes stapled to an instructions sheet. You'll need a 7/32" or 5.5mm nutdriver and a 5/64" or 2mm Allen key for tightening.

Any one Tried these?

www.newegg.com

www.newegg.com

10pcs 14mm plastic nail Southbridge Northbridge cooling fan plastic spring clips secure the heat sink - Newegg.com

Buy 10pcs 14mm plastic nail Southbridge Northbridge cooling fan plastic spring clips secure the heat sink with fast shipping and top-rated customer service. Once you know, you Newegg!

They look perfect. Might have to buy them to just have some aroundAny one Tried these?

10pcs 14mm plastic nail Southbridge Northbridge cooling fan plastic spring clips secure the heat sink - Newegg.com

Buy 10pcs 14mm plastic nail Southbridge Northbridge cooling fan plastic spring clips secure the heat sink with fast shipping and top-rated customer service. Once you know, you Newegg!www.newegg.com

I am afraid it would cracking processor board for long terms with fixed bolt nut set above, because with plastic one it would allows slight movement for heatsink when heats up. With metal bolt screwed in place, it doesn’t allow slight movement when heatsink heats up. Same with train railway without gaps.

Somehow I am still preferred push pin solution, when it breaks, I can replaced relatively easy and cheap. Most of PCs north bridge / NIC chips are using this kind of spring retainer design.

But yeah it have retention springs so I assume it would behave like some GPU heatsink retainer, it should be safer compared with traditional fixed bolt.

Somehow I am still preferred push pin solution, when it breaks, I can replaced relatively easy and cheap. Most of PCs north bridge / NIC chips are using this kind of spring retainer design.

But yeah it have retention springs so I assume it would behave like some GPU heatsink retainer, it should be safer compared with traditional fixed bolt.

Last edited:

My diode was at 100C yesterday...no fans! Installed fan mgmnt and cooled it down but still running 85-90C. Funny I hadn't noticed no fan noise in a while...grew immune I guess. Anyways, it looks like I'll be doing new paste stuff soon...did these clips work? Looks like I need to orderThey look perfect. Might have to buy them to just have some around

clips

IPA (Electronic grade?)

qtips

antistat mat

thermal pad or paste

antistat brush

Please let me know about the clips

I am afraid it would cracking processor board for long terms with fixed bolt nut set above, because with plastic one it would allows slight movement for heatsink when heats up. With metal bolt screwed in place, it doesn’t allow slight movement when heatsink heats up.

That's not an issue. If you notice, the original springs are used on the metal bolts. No difference between them and the original nylon pins.

I ordered the majority of items...now just wondering about the paste or pad....what brand and pad thickness do you recommend? TIAMy diode was at 100C yesterday...no fans! Installed fan mgmnt and cooled it down but still running 85-90C. Funny I hadn't noticed no fan noise in a while...grew immune I guess. Anyways, it looks like I'll be doing new paste stuff soon...did these clips work? Looks like I need to order

clips

IPA (Electronic grade?)

qtips

antistat mat

thermal pad or paste

antistat brush

Please let me know about the clips

There is no thermal pad between the NB heatsink and the chip. You only need thermal paste. Any popular thermal paste can do the job. e.g. AS5, MX-4, NT-H1...I ordered the majority of items...now just wondering about the paste or pad....what brand and pad thickness do you recommend? TIA

The NB heatsink itself is too small, even you go for the very high end thermal paste, the cooling performance still roughly the same.

Spin up the fans a little bit can easily cool down the NB a few degrees. No need to spend too much on the thermal paste. Any non conductive silicone based thermal paste can do the job.

I also recommend these metal rivets. Come with instructions:

Mac Pro 4,1 and 5,1 Northbridge heatsink retainer spring kit | eBay

This precision spring kit is the definitive answer to repairing your Mac Pro 4,1 and 5,1 Northbridge heat sink broken rivets. Fix your Mac Pro before you have a catastrophic failure like many have already.

www.ebay.com

I also recommend these metal rivets. Come with instructions:

Mac Pro 4,1 and 5,1 Northbridge heatsink retainer spring kit | eBay

This precision spring kit is the definitive answer to repairing your Mac Pro 4,1 and 5,1 Northbridge heat sink broken rivets. Fix your Mac Pro before you have a catastrophic failure like many have already.www.ebay.com

Cool they finally have a kit available. When I did this repair, I essentially had to guess as to whether or not the Chinese rivets I had ordered would fit. That which is concealed underneath one of the heatsinks (dual-CPU model) needed its nub and spring-jacket shortened.

Today i have repasted my Northbridge

For snap rivet i have used DIN 7984 M3 x 14mm screws with a flatter head

(I'm really sure a M3 x 12mm is long enough and is the better choice,

because i shortened the screw under CPU-Cooler to be on the safe side)

Between the head and the board i used a washer

M2.5 washer on a M3 screw, perfect.

Screws before shortened. I have used the springs form the original snap rivet.

Thermal paste was Thermal Grizzly Kryonaut. CPUs and Northbridge are around 3-4 degrees cooler at same fan settings.

For snap rivet i have used DIN 7984 M3 x 14mm screws with a flatter head

(I'm really sure a M3 x 12mm is long enough and is the better choice,

because i shortened the screw under CPU-Cooler to be on the safe side)

Between the head and the board i used a washer

M2.5 washer on a M3 screw, perfect.

Screws before shortened. I have used the springs form the original snap rivet.

Thermal paste was Thermal Grizzly Kryonaut. CPUs and Northbridge are around 3-4 degrees cooler at same fan settings.

Last edited:

Today i have repasted my Northbridge

For snap rivet i have used DIN 7984 M3 x 14mm screws with a flatter head

(I'm really sure a M3 x 12mm is long enough and is the better choice,

because i shortened the screw under CPU-Cooler to be on the safe side)

IMO there's no need to cut the screws to a certain length .

You could mount the screws with the heads up and nut down = the other way around.

This way the length is not critical, as long as its more than ~ 13mm.

There's more than enough distance between the pcb and the aluminium plate underneath to use e.g.16mm screws.

It looks like you overtightened the screws a lot.

Looking at the picture it's even hard to tell if there's a spring between the nut and the heatsink!

Before replacing the plastic rivets I measure the distance between the heatsink and the head of the screw and tighten the new screws so that the original distance is maintained.

This way the pressure will be the same as with the original rivets.

Too much pressure will damage the NB die and/or the pcb.....

The Delta NB heatsink- die is 16 degrees after the repaste.

Based on my experience it should be somewhere between 7 and max 12 degrees after a repaste....

Sorry for being critical, best intentions

Attachments

Last edited:

The Delta NB heatsink- die is 16 degrees after the repaste.

Based on my experience it should be somewhere between 7 and max 12 degrees after a repaste....

Sorry for being critical, best intentions

The Delta between NB and heatsink was so bad from the fist day.

Where your experience came from? Dual or Single? CPU frequency? Fan settings?

Distance is finally near the same, but i think i will bring the head of the screw up like you say before i will wait for your Delta informations.Before replacing the plastic rivets I measure the distance between the heatsink and the head of the screw and tighten the new screws so that the original distance is maintained.

This way the pressure will be the same as with the original rivets.

Is it possible that the contact of the IOH heatsink temp sensor can make the difference (better contact =lower Delta)?

Last edited:

just re-pasted a Dual 3,46 Six Core Board

Northbridge from 20 Delta to 12. Paste was dry as a bone.

before:

after:

I used Nylon Clips

Northbridge from 20 Delta to 12. Paste was dry as a bone.

before:

after:

I used Nylon Clips

Hey Macschrauber, alte Säge 😉just re-pasted a Dual 3,46 Six Core Board

Northbridge from 20 Delta to 12. Paste was dry as a bone.

before:

View attachment 1790920

after:

View attachment 1790924

I used Nylon Clips

What thermal paste did you used?

Nothing special, Arctic MX-4, spread methodHey Macschrauber, alte Säge 😉

What thermal paste did you used?

Last edited:

Previously helped a client with his Northbridge temperature problem. I replaced his old plastic rivets with stainless steel nuts and bolts and reused the springs. Before the fixing, the temps were at 87°C. After repasting a new thermal paste with the stainless steel nuts and bolts, the temperature went down to 70°C

Last edited:

My 4,1>5,1 N.B. cooling experiences.

Currently I use the nut+bolt + original springs + non-conductive washers

gets interesting from post#15

forums.macrumors.com

forums.macrumors.com

Currently I use the nut+bolt + original springs + non-conductive washers

gets interesting from post#15

De-Dusting & Northbridge temp reduction in Dual CPU cMP 4,1 & 5,1

( NOTE : I feel that both Northbridge temp reduction AND de-dusting/de-clogging the cheesegrater DUAL CPU cMPs deserves a separate thread to embrace the concepts. Northbridge cooling requires that all that hot air be efficiently extracted from the CPU case...

Thanks for sharing your well written post and helpful photos in showing a cooling method for the Northbridge. Good to know the nut and bolt, washers can work.My 4,1>5,1 N.B. cooling experiences.

Currently I use the nut+bolt + original springs + non-conductive washers

gets interesting from post#15

De-Dusting & Northbridge temp reduction in Dual CPU cMP 4,1 & 5,1

( NOTE : I feel that both Northbridge temp reduction AND de-dusting/de-clogging the cheesegrater DUAL CPU cMPs deserves a separate thread to embrace the concepts. Northbridge cooling requires that all that hot air be efficiently extracted from the CPU case...forums.macrumors.com

US $0.57 31% Off | 10pcs 14mm Plastic Nail Southbridge Northbridge Cooling Fan Plastic Spring Clips Secure The Heat Sink

~3$ shipped

~3$ shipped

Just my 46 cents, here. I have just finished completely refurbishing 2 Mac Pro (5,1 - 2010-2012) CPU trays (and am about to do a third) and have had to deal with this problem. In both cases, the original plastic rivets and springs were intact but, after reading numerous reports of failure over time, I sought a more permanent, reliable and (hopefully) elegant solution. The following approach solved the problem for less than $0.50:

1) I carefully used pliers to squeeze the barbed end of the original rivets and coaxed them through the PCB holes. Then carefully removed the springs, without ruining the barbs, and set the rivets aside for possible future emergency use (although, with the solution I arrived at, I cannot imagine when I would ever use them - "waste-not, want-not", I guess).

2) Replaced each spring-rivet with an M3-.5mm x 14mm stainless steel button-head screw and an M3-.5mm stainless steel nylon-insert locking nut, re-using the original spring. A length of 14mm is perfect; a 12mm length will compress the springs to (or past) their limits; a 16mm length will contact the CPU tray.

(NOTE: I read this how-to article on ifixit.com in which the author used 16mm screws and had to drill a hole in the tray to accommodate the excess screw length but the excess length is just that: excess. I avoid invasive operations unless there's an excellent reason to perform them. The author also used normal cap-head screws and used washers under the screw heads to properly retain the springs; a button-head screw has a very flat, larger-diameter head that is perfect for the spring, obviating the need for washers (looks more elegant, too). Also, he used a nylon washer on the bottom of the PCB but, as tsialex pointed out, the bottom is a ground plane anyway and requires no such insulation.)

3) Cleaned and applied thermal compound to the Northbridge chip (of course).

4) Assembled, adjusting the tension to close-to-original by ensuring that the distance from the bottom of the button-head of the screw to the PCB surface was equal to that of the original spring-rivet (about 9/32") This resulted in a spring pressure that approximates that of the original quite closely.

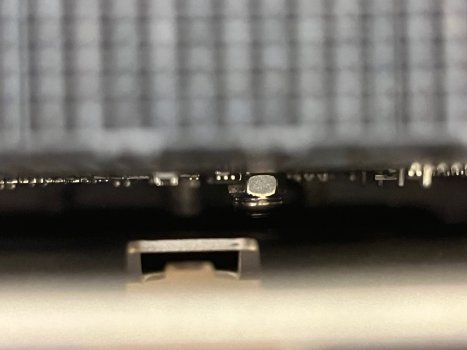

As you can see, the fix is permanent, trouble-proof, easy to disassemble/reassemble, if necessary, and elegant. The next illustration shows the nuts under the PCB in the assembled CPU tray; as can be seen, the 14mm screw length results in full engagement of the nylon locking insert with a minimum of protruding thread and plenty of clearance between the screws and the tray itself.

Here are the parts labels with complete specs for those who may find this approach desirable:

There are, of course, many ways to solve almost any problem; this one works and works well and is very economical (the total cost of the project was $0.46).

1) I carefully used pliers to squeeze the barbed end of the original rivets and coaxed them through the PCB holes. Then carefully removed the springs, without ruining the barbs, and set the rivets aside for possible future emergency use (although, with the solution I arrived at, I cannot imagine when I would ever use them - "waste-not, want-not", I guess).

2) Replaced each spring-rivet with an M3-.5mm x 14mm stainless steel button-head screw and an M3-.5mm stainless steel nylon-insert locking nut, re-using the original spring. A length of 14mm is perfect; a 12mm length will compress the springs to (or past) their limits; a 16mm length will contact the CPU tray.

(NOTE: I read this how-to article on ifixit.com in which the author used 16mm screws and had to drill a hole in the tray to accommodate the excess screw length but the excess length is just that: excess. I avoid invasive operations unless there's an excellent reason to perform them. The author also used normal cap-head screws and used washers under the screw heads to properly retain the springs; a button-head screw has a very flat, larger-diameter head that is perfect for the spring, obviating the need for washers (looks more elegant, too). Also, he used a nylon washer on the bottom of the PCB but, as tsialex pointed out, the bottom is a ground plane anyway and requires no such insulation.)

3) Cleaned and applied thermal compound to the Northbridge chip (of course).

4) Assembled, adjusting the tension to close-to-original by ensuring that the distance from the bottom of the button-head of the screw to the PCB surface was equal to that of the original spring-rivet (about 9/32") This resulted in a spring pressure that approximates that of the original quite closely.

As you can see, the fix is permanent, trouble-proof, easy to disassemble/reassemble, if necessary, and elegant. The next illustration shows the nuts under the PCB in the assembled CPU tray; as can be seen, the 14mm screw length results in full engagement of the nylon locking insert with a minimum of protruding thread and plenty of clearance between the screws and the tray itself.

Here are the parts labels with complete specs for those who may find this approach desirable:

There are, of course, many ways to solve almost any problem; this one works and works well and is very economical (the total cost of the project was $0.46).

Attachments

Last edited:

Valdaquendë, this is a most informative and straightforward treatment of the Northbridge heat sink pins question. The photos are a huge help, especially the hardware packages. This is so much better than waiting a week or so for something to show up as it's now just a quick trip to the local (Ace) hardware store. Thank you!

Register on MacRumors! This sidebar will go away, and you'll see fewer ads.