@mmyk "...what is the general consensus for JRY SA1/FA1/AA1 board builds regarding cooling?"

If you put a 50 watt incandescent light bulb inside a sealed iMac case it will get quite hot after a while...

But, it won't be a problem as the aluminium case will dissipate this heat, so it won't rise to dangerous levels...

...for a light bulb, which is designed to run its filament at over 2000º...

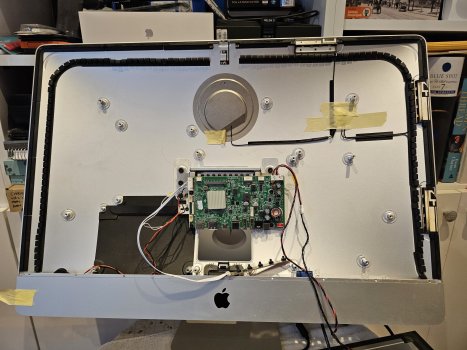

The heatsink of the JRY--SA1 is designed to be fitted vertically against the back case ventilation slots above and below it.

This give adequate airflow over the heatsink fins.

In an iMac conversion, there is space for an internal airflow, but the air will heat up if it is trapped inside.

It doesn't seem to heat up too much so it kills the boards, because of the aluminium case, but it's anyone's guess if this actually shortens the life of the boards?

Allowing airflow over the rear of the board is definitely a good idea, and I'm doubtful if attaching a board directly against a 3D printed backing plate can be a good thing. 😱

Experience has shown that in practice the amount of airflow needed is actually very low, far less than the original iMac fan provides unless it is slowed right down.

I personally used the smaller fan from a 21.5" A1418 iMac, running at its slowest setting using a 4 wire PWM controller.

But most people don't seem to bother.....

If you put a 50 watt incandescent light bulb inside a sealed iMac case it will get quite hot after a while...

But, it won't be a problem as the aluminium case will dissipate this heat, so it won't rise to dangerous levels...

...for a light bulb, which is designed to run its filament at over 2000º...

The heatsink of the JRY--SA1 is designed to be fitted vertically against the back case ventilation slots above and below it.

This give adequate airflow over the heatsink fins.

In an iMac conversion, there is space for an internal airflow, but the air will heat up if it is trapped inside.

It doesn't seem to heat up too much so it kills the boards, because of the aluminium case, but it's anyone's guess if this actually shortens the life of the boards?

Allowing airflow over the rear of the board is definitely a good idea, and I'm doubtful if attaching a board directly against a 3D printed backing plate can be a good thing. 😱

Experience has shown that in practice the amount of airflow needed is actually very low, far less than the original iMac fan provides unless it is slowed right down.

I personally used the smaller fan from a 21.5" A1418 iMac, running at its slowest setting using a 4 wire PWM controller.

But most people don't seem to bother.....