Got a tip for us?

Let us know

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

Who has or is planning to get an electric car / EV Talk

- Thread starter PracticalMac

- Start date

- Sort by reaction score

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

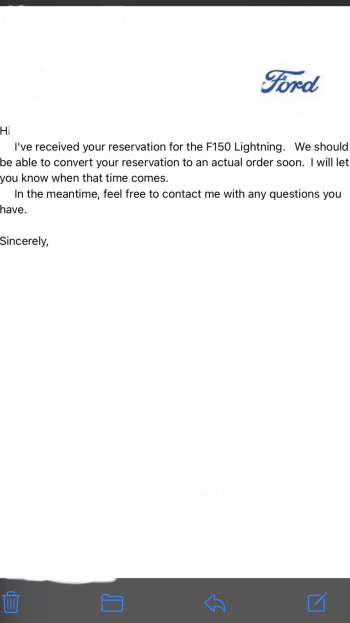

Welp, just got this E-mail sent to me (Heavily redacted for obvious reasons.) Looks like I’ll be finalizing in a few weeks. According to my sales consultant, he’s saying the end of 2022, it will be delivered. But I suspect he might be off a month or two, and I’d wager January 2023. [And that’s based off local discussion with others who are ahead of me.]I agree - while the Rivian is not my cup of tea, the pricing is just way up there - almost as if they are trying to gain the Hummer EV group of buyers.

The GM line of EV trucks & SUV will be their main competitor IMO.

The Ford Lightning and Tesla Cybertruck will be for the majority of consumers who are realistic.

Can't wait to get my "affordable" Lightning truck - never a Ford truck customer in the past, but the $11,500 discount is really appealing.

Did you receive anything like this?

Attachments

Welp, just got this E-mail sent to me (Heavily redacted for obvious reasons.) Looks like I’ll be finalizing in a few weeks. According to my sales consultant, he’s saying the end of 2022, it will be delivered. But I suspect he might be off a month or two, and I’d wager January 2023. [And that’s based off local discussion with others who are ahead of me.]

Did you receive anything like this?

I am a little shocked by the pixelated logo and poor off white background behind it. Seems shoddy for a company the size of Ford to send something like that out considering their slick brand guidelines. I hope your order is handled better than their mailings

I am a little shocked by the pixelated logo and poor off white background behind it. Seems shoddy for a company the size of Ford to send something like that out considering their slick brand guidelines. I hope your order is handled better than their mailings

You’re misunderstanding. I literally used a ‘white out’ tool to redact all my personal info and everything that would show the name of the dealership, the sales consultants name, my info (My email address, home address, phone number was all on this document), I left only just the order info to see if @4sallypat received anything similar.

Alternatively, This is the same e-mail, except ‘blacked out.’

Attachments

I understood that you redacted your personal information as you explained that in the post I quoted. Don’t worry, all good

You should see what Tesla sends you. It legit looks like a scammerI am a little shocked by the pixelated logo and poor off white background behind it. Seems shoddy for a company the size of Ford to send something like that out considering their slick brand guidelines. I hope your order is handled better than their mailings

There was one member here, who owned an M3, and sold it in place of another German car, simply because they missed the engine sounds, dynamics, ect. So for some people, it is a drastic change, but really requires an adaptation process.

It’s a good thing the Ford Mach E has the simulated engine sounds

Any power plug will charge an EV. For my usage, a 110v / 15a plug is enough for the daily distance I drive.Hybrid first then EV. I live in a poor country so charging stations has an average of one per city in NCR or one per region.

Reglaress, best if you get a PLUG-IN Hybrid. That will give you EV advantage with a gasoline backup.

It’s a good thing the Ford Mach E has the simulated engine sounds

VROOM VROOM!!!

I understand that Ford has 150,000 orders for the Lightning!You’re misunderstanding. I literally used a ‘white out’ tool to redact all my personal info and everything that would show the name of the dealership, the sales consultants name, my info (My email address, home address, phone number was all on this document), I left only just the order info to see if @4sallypat received anything similar.

Alternatively, This is the same e-mail, except ‘blacked out.’

Being that I sold my house last month and will be living in an apartment for evermore, I elected to buy a Hybrid. I bought a 2022 Honda CR-V hybrid touring. I'm getting about 36mpg which is about 10 mpg more than a 2019 non Hybrid CR-V that I sold last month. Pretty good for an SUV I think. I may also be trading in my 2019 Accord for a Hybrid Accord whenever I can find one.

I’m curious where you learned of that? That actually seems relatively low. I wonder if that is even including commercial orders, aside from consumer orders.I understand that Ford has 150,000 orders for the Lightning!

I placed my reserve a little over six weeks ago, so it’s difficult to say when I would receive mine. Which leads me to think, let’s assume Ford has 150,000 confirmed total orders for the Ford Lightning, how many can they actually fulfill annually?

**********************

In other news, looking at the Tesla Model 3 long range, it’s showing a delivery under 60 days. That’s pretty good, considering two months ago, they were predicting six months or longer.

CARpocalypse, or the second great seismic cultural disruption whose name is "BEV" (Battery Electric Vehicle).

Nissan was the next to bet big on the BEV gamble (there was others but they were small). Despite mundane performance and initial range less than 100 miles the LEAF was a solid entry and what one can say was the first succesful EV (clue 3)

After seeing what happened to the EV1, in 2003 some pretty smart people came together bit by bit to make a new car company that will make the dream of BEV a reality. Elon Musk joined Tesla a few months after its founding, but did so with gusto and $6.5 million.

Fast forward from 2003 to 2021.

EV technology has surpassed the drive performance of ICE (internal combustion engine) cars (Model S Plaid is the fastest production car ever made).

Enormous demand for BEV's, car companies that produce them have months of back orders for EV.

BEV is significantly superior over non-Plug-in Hybrids (HEV, not PHEV).

2021 is year when all car makers announced EV plans or introduced an EV vehicle to market.

BEV's now offer on average 200 miles, with some going well past 300 mile range.

Recharging to 80% power is from 15 to 40 minuets, depending on the make (some early designs offer less then 10).

The 900kg gorilla in room is Tesla.

Tesla has been nearly doubling its production rate every year since 2019, now has two new Gigafactory plants in Berlin and Austin set to begin production any day now (as of post date, rumors they are doing test builds) with claimed official for sale production set for 2 Jan 2022. Work has already started to expand those locations, and the China plant, with rumors of another location being selected. Tesla's goal is 20,000,000 cars per year in 2030

Of all the major car companies Volkswagen is producing the most and in several models of BEV, but recently realized and admitted they are slow to switch and are failing behind Tesla in EV production capacity. 2021 Tesla built more BEV than all the other BEVs made in Europe, and that lead is expected to grow.

Other car companies are have only just started with 6 to 18 months to ramp up to full production, and those that have production are encountering quality issues, like Chevy Bolt EV bursting into flame (a la Samsung Galaxy Note 7 but not quite as common).

As little as a year ago other car companies did not see Tesla as a threat at all, now many of them recognize Tesla as significant competition.

This is why:

Tesla makes its own batteries. Not on does it have tight control on production schedule, but it also able to develop better batteries that cost less to make and improve car performance, the latest is the 4680 Battery designed to hold more energy and be less expensive to make, resulting in faster price reductions. Conversely the Chevy Bolt battery was made by LG Chem in Korea.

Tesla also makes nearly all the microprocessors used in its cars, so has barely been impacted by the global supply shortage.

Also the car design is made with as few parts as possible, drastically reducing production time.

What Tesla has done is both "Moore's Law" (more here), and "Wright's Law".

Wright's Law you wonder?

Theodore Paul Wright, also known as T. P. Wright, worked in aviation industry (I think no relation to the famous brothers) and during his time he discovered this:

It is very possible in less than 8 years Tesla cars will be cheaper to buy than comparable ICE cars, in addition cheaper to operate, longer life, and better performance.

Demand for ICE cars will cease practically overnight, car companies slow to transition will vanish as well.

The ACE card in Tesla's pocket: its charging network is far more reliable, faster, and easier to use.

Non-Tesla stations quite often do not work.

PS: Yes, there is far, far more to this than what I wrote, but the fundamentals point to this happening. 2022 will be the tell for what happens to the future of automotive.

PPS: I do fully expect to see a major upset in traditional auto industry, even if the companies do transition and survive. Also the auto fuel petroleum industry.

- IOW: Current ICE (internal combustion engine) car companies will massive declines, some will go bankrupt as they struggle to swtich to BEV.

- When? In as little as 8 years.

- Why? BEV's are simply superior in nearly every metric over ICE, and its remaining weaknesses will diminish over time.

- How? The technology was there, the demand was there, all it needed was a spark.

Nissan was the next to bet big on the BEV gamble (there was others but they were small). Despite mundane performance and initial range less than 100 miles the LEAF was a solid entry and what one can say was the first succesful EV (clue 3)

After seeing what happened to the EV1, in 2003 some pretty smart people came together bit by bit to make a new car company that will make the dream of BEV a reality. Elon Musk joined Tesla a few months after its founding, but did so with gusto and $6.5 million.

Fast forward from 2003 to 2021.

EV technology has surpassed the drive performance of ICE (internal combustion engine) cars (Model S Plaid is the fastest production car ever made).

Enormous demand for BEV's, car companies that produce them have months of back orders for EV.

BEV is significantly superior over non-Plug-in Hybrids (HEV, not PHEV).

2021 is year when all car makers announced EV plans or introduced an EV vehicle to market.

BEV's now offer on average 200 miles, with some going well past 300 mile range.

Recharging to 80% power is from 15 to 40 minuets, depending on the make (some early designs offer less then 10).

The 900kg gorilla in room is Tesla.

Tesla has been nearly doubling its production rate every year since 2019, now has two new Gigafactory plants in Berlin and Austin set to begin production any day now (as of post date, rumors they are doing test builds) with claimed official for sale production set for 2 Jan 2022. Work has already started to expand those locations, and the China plant, with rumors of another location being selected. Tesla's goal is 20,000,000 cars per year in 2030

Of all the major car companies Volkswagen is producing the most and in several models of BEV, but recently realized and admitted they are slow to switch and are failing behind Tesla in EV production capacity. 2021 Tesla built more BEV than all the other BEVs made in Europe, and that lead is expected to grow.

Other car companies are have only just started with 6 to 18 months to ramp up to full production, and those that have production are encountering quality issues, like Chevy Bolt EV bursting into flame (a la Samsung Galaxy Note 7 but not quite as common).

As little as a year ago other car companies did not see Tesla as a threat at all, now many of them recognize Tesla as significant competition.

This is why:

Tesla makes its own batteries. Not on does it have tight control on production schedule, but it also able to develop better batteries that cost less to make and improve car performance, the latest is the 4680 Battery designed to hold more energy and be less expensive to make, resulting in faster price reductions. Conversely the Chevy Bolt battery was made by LG Chem in Korea.

Tesla also makes nearly all the microprocessors used in its cars, so has barely been impacted by the global supply shortage.

Also the car design is made with as few parts as possible, drastically reducing production time.

What Tesla has done is both "Moore's Law" (more here), and "Wright's Law".

Wright's Law you wonder?

Theodore Paul Wright, also known as T. P. Wright, worked in aviation industry (I think no relation to the famous brothers) and during his time he discovered this:

Article here.While studying airplane manufacturing, Wright determined that for every doubling of airplane production the labor requirement was reduced by 10-15%. In 1936, he detailed his full findings in the paper “Factors Affecting the Costs of Airplanes.” Now known as “Wright’s Law”, or experience curve effects, the paper described that “we learn by doing” and that the cost of each unit produced decreases as a function of the cumulative number of units produced.

It is very possible in less than 8 years Tesla cars will be cheaper to buy than comparable ICE cars, in addition cheaper to operate, longer life, and better performance.

Demand for ICE cars will cease practically overnight, car companies slow to transition will vanish as well.

The ACE card in Tesla's pocket: its charging network is far more reliable, faster, and easier to use.

Non-Tesla stations quite often do not work.

PS: Yes, there is far, far more to this than what I wrote, but the fundamentals point to this happening. 2022 will be the tell for what happens to the future of automotive.

PPS: I do fully expect to see a major upset in traditional auto industry, even if the companies do transition and survive. Also the auto fuel petroleum industry.

So far Ford has said 50 to 60 thousand electric trucks a year.I’m curious where you learned of that? That actually seems relatively low. I wonder if that is even including commercial orders, aside from consumer orders.

I placed my reserve a little over six weeks ago, so it’s difficult to say when I would receive mine. Which leads me to think, let’s assume Ford has 150,000 confirmed total orders for the Ford Lightning, how many can they actually fulfill annually?

**********************

In other news, looking at the Tesla Model 3 long range, it’s showing a delivery under 60 days. That’s pretty good, considering two months ago, they were predicting six months or longer.

That sounds about right. Can you share where you read or heard of this? I’m probably in the late second stage of production or third stage. My order ‘goes live’ in January. Production is slated for late January for first builds.So far Ford has said 50 to 60 thousand electric trucks a year.

I’m also curious how many orders Tesla can churn with the Cybertruck in comparison, now with the Texas location being a secondary hub.

That sounds about right. Can you share where you read or heard of this? I’m probably in the late second stage of production or third stage. My order ‘goes live’ in January. Production is slated for late January for first builds.

I’m also curious how many orders Tesla can churn with the Cybertruck in comparison, now with the Texas location being a secondary hub.

Ford doubles electric F-150 Lightning production plan, and it's still not enough

Ford is planning to double production of their upcoming F-150 Lightning electric pickup truck, according to Reuters. The move comes...

electrek.co

electrek.co

Apparently 50-60k isn’t until 2023. They expect to make 15 thousand trucks next year….

🤦🏽♂️

I think 36mpg for a hybrid is a very good reason to stick with my ICE Golf. I get 46mpg.Being that I sold my house last month and will be living in an apartment for evermore, I elected to buy a Hybrid. I bought a 2022 Honda CR-V hybrid touring. I'm getting about 36mpg which is about 10 mpg more than a 2019 non Hybrid CR-V that I sold last month. Pretty good for an SUV I think. I may also be trading in my 2019 Accord for a Hybrid Accord whenever I can find one.

I would like an electric car that can autonomous drive itself to a charger and top off the battery. Whenever I call it it would need to pick me up with a full charge then. The charging keeps me from wanting any electric car. I live in a city and there are no chargers around my place. I don't want to drive myself to chargers, wait there and start to have to fight with idiots for who came first and such. Automate this please. Range is the next issue. Not good enough. I want heating and still enough range even with an old battery for sudden traffic jams and detours anytime.

With all the logistical issues companies are experiencing across the globe, unfortunately this is just how it’s going to be until things can pan out. But I think for Ford, hopefully they just put a lot of quality control into the first edition models, given that there is a limited number of them being produced.

Ford doubles electric F-150 Lightning production plan, and it's still not enough

Ford is planning to double production of their upcoming F-150 Lightning electric pickup truck, according to Reuters. The move comes...electrek.co

Apparently 50-60k isn’t until 2023. They expect to make 15 thousand trucks next year….

🤦🏽♂️

Oh, and your post made me think of this ‘Gif’ for my order ⬇️

😁

Attachments

It would be nice if you can pop the battery out, bring it in the house and charge it. Then in the morning, you carry the battery to the car and plug it in. That would help me a lot so long as the battery is under 50 pounds.

It would be nice if you can pop the battery out, bring it in the house and charge it. Then in the morning, you carry the battery to the car and plug it in. That would help me a lot so long as the battery is under 50 pounds.

I've heard some of the battery assemblies weigh well over 100 pounds (250 and up). I'd imagine unplugging from the car could arc too potentially.

I've heard some of the battery assemblies weigh well over 100 pounds (250 and up). I'd imagine unplugging from the car could arc too potentially.

I am hoping that Tony Stark clone at Tesla will figure this stuff out.

That specific situation would be rather unique, because not every condo owner typically is ‘long-term’ ownership. So let’s take a holding company for example, that maybe owns those condos and why would they want to invest in EV infrastructure if they have a turnover of people that maybe use those condos as a ‘winter getaway or summer vacation’ home, or maybe they sell them for other XYZ reasons. Where I’m from, that’s totally common tactics here.Our condo has some EV advocates, but the cost to put chargers in the underground parking lot is around $10,000 per space IF the grid can support all of them. More complicated than some realize.

If you think about it, that’s a huge investment, and I don’t see condos expanding into EV infrastructure, unless the surrounding demographic of your region is also investing into EV infrastructure.

Register on MacRumors! This sidebar will go away, and you'll see fewer ads.