Is there anyone in the U.K. (preferably south East) offering a de-lidding service, who would be prepared to de-lid a pair of X5690's for me?

Got a tip for us?

Let us know

Become a MacRumors Supporter for $50/year with no ads, ability to filter front page stories, and private forums.

4.1 Dual CPU Delid? or Leave the lid down?

- Thread starter Vicromono

- Start date

- Sort by reaction score

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is there anyone in the U.K. (preferably south East) offering a de-lidding service, who would be prepared to de-lid a pair of X5690's for me?

there are resellers who offer already delidded CPUs.. but maybe you have yours already?

Hi There, yes i already have my X5690'sthere are resellers who offer already delidded CPUs.. but maybe you have yours already?

Hi There, yes i already have my X5690's

If you wish, I can delid them for you for a reasonable price.

I am located in Copenhagen, Denmark though

We don't really have a shop or a delidding business, so there's that - but I guess 50£ will be fine for us

On the same day I receive the CPUs I will ship back the delidded, tested CPUs

Just send me a private message if interested.

On the same day I receive the CPUs I will ship back the delidded, tested CPUs

Just send me a private message if interested.

I did see that one, think the guy is in greece, i had a look at his feedback and couldn't see any from people who had the service done though.I think i saw a delid service on ebay UK for £80

[doublepost=1488396998][/doublepost]

That sounds quite a fair price itdk92, and will message you as soon as i reply on here. Does anyone know the approx price for a small parcel for postage to Denmark from the U.K.?We don't really have a shop or a delidding business, so there's that - but I guess 50£ will be fine for us

On the same day I receive the CPUs I will ship back the delidded, tested CPUs

Just send me a private message if interested.

Anyone know of someone who provides a delidding service in New Zealand or Australia? It's too costly to send them overseas to get delidded (two X5680's).

The vice delidding method worked quite well for me. I thought about doing a writeup with pictures, but there are YouTube videos that show the process more clearly than a series of pictures would.

Don't forget that there are options for not delidding at all, such as the washer stack.

Don't forget that there are options for not delidding at all, such as the washer stack.

I've just bought my 3rd Mac Pro, a 4,1 that I've firmware upgraded to 5,1. It's a dual CPU 2.26GHz 8GB ram model that I will upgrade to two X5680's and 32GB ram (waiting for both to arrive in the post), so a step up from my other single Hex-core 3.33GHz X5680. I'll move my SSD's, GPU, HDDs etc across to the new dual CPU model. This will max my machine out for me - no more upgrades after that.

Now for upgrading the CPUs to those more powerful X5380's.

I've read far too much on the topic, so much that I am still kinda sitting on the fence as to whether to delid or not. I've watched several videos for upgrading and can't make my mind up on which way to go now - too much information and now too much over-thinking. My apologies to those who have taken the plunge and who don't have time for those who want quick answers - that isn't me - I've spent two weeks of reading and watching.

If I were to delid:

What do you use on the vice to soften the contact of the CPU with the vice? Cloth, plastic, cardboard etc?

Exactly how hard is it to remove the solder once the IHS is off? Videos talk about how malleable it is, but it looks like quite a struggle, and very time consuming.

I see one video it discusses using 600 sandpaper to remove the excess solder, and only moving it in one direction across the top of the CPU. What if you go too far and sand too much off? How easy does it come off with the sandpaper?

If I don't delid:

Washers or no washers? DO they have a model number and dimensions? Are they plastic, metal etc?

What's the go with unclipping the fan connector and tucking the cables? Is there a chance they could connect with the heatsink and melt/burn through the fan cables? Can someone show a close-up video of how to unclip/sort out the heatsink cable connector and wires?

If there was a definitive place to go that is the absolute bible on this topic, can someone please provide me with where it is. Nervous as hell about the whole thing, and probably shouldn't be. I've previously upgraded my 1,1>2,1 to dual 3GHz CPUs, and my 4,1>5,1 from Quad-Core to Hexa-Core, so I've have a little experience, but I don't overrate myself. Cheers for any advice, links etc that will help me build my confidence, otherwise this new dual CPU beast might not ever realise its awesome potential.

Now for upgrading the CPUs to those more powerful X5380's.

I've read far too much on the topic, so much that I am still kinda sitting on the fence as to whether to delid or not. I've watched several videos for upgrading and can't make my mind up on which way to go now - too much information and now too much over-thinking. My apologies to those who have taken the plunge and who don't have time for those who want quick answers - that isn't me - I've spent two weeks of reading and watching.

If I were to delid:

What do you use on the vice to soften the contact of the CPU with the vice? Cloth, plastic, cardboard etc?

Exactly how hard is it to remove the solder once the IHS is off? Videos talk about how malleable it is, but it looks like quite a struggle, and very time consuming.

I see one video it discusses using 600 sandpaper to remove the excess solder, and only moving it in one direction across the top of the CPU. What if you go too far and sand too much off? How easy does it come off with the sandpaper?

If I don't delid:

Washers or no washers? DO they have a model number and dimensions? Are they plastic, metal etc?

What's the go with unclipping the fan connector and tucking the cables? Is there a chance they could connect with the heatsink and melt/burn through the fan cables? Can someone show a close-up video of how to unclip/sort out the heatsink cable connector and wires?

If there was a definitive place to go that is the absolute bible on this topic, can someone please provide me with where it is. Nervous as hell about the whole thing, and probably shouldn't be. I've previously upgraded my 1,1>2,1 to dual 3GHz CPUs, and my 4,1>5,1 from Quad-Core to Hexa-Core, so I've have a little experience, but I don't overrate myself. Cheers for any advice, links etc that will help me build my confidence, otherwise this new dual CPU beast might not ever realise its awesome potential.

By considering it's relatively easy to delid the CPU. These kind of CPU delid tool avail on internet for just $2.

I just can't see why should we risk the socket and intentionally damage the fan connector etc to install the CPU.

And obviously, you have more concern on the non delid route. I will say it makes more sense to just delid the CPU.

I just can't see why should we risk the socket and intentionally damage the fan connector etc to install the CPU.

And obviously, you have more concern on the non delid route. I will say it makes more sense to just delid the CPU.

These kind of CPU delid tool avail on internet for just $2.

I looked, but could never find one that would fit Westmere chips. Only Haswell, Ivy Bridge, Devil's Canyon, Skylake, and Kabylake.

I ended up using my vice, which worked perfectly.

What do you use on the vice to soften the contact of the CPU with the vice? Cloth, plastic, cardboard etc?

Exactly how hard is it to remove the solder once the IHS is off?

I used two layers of duct tape on the jaw that contacted the PCB, and nothing at all on the jaw that contacted the lid.

The solder comes off very easily. I used a razor window scraper. It only took a few minutes. Someone has said it is so soft that he used a credit card.

So h9826790, can you confirm that the tool would work for the Westmere CPU? It only says it works with those other CPU models. If you've personally used it and it worked then I'll get one.

ActionableMango - thanks for covering that off. If someone can confirm100% that the deluding tool works for Westmere chips, then I'll go for that option - saves me having to buy a vice just for the operation.

And do you still use a razor blade to break the outer bond around the edges of the CPU before using the vice method?

ActionableMango - thanks for covering that off. If someone can confirm100% that the deluding tool works for Westmere chips, then I'll go for that option - saves me having to buy a vice just for the operation.

And do you still use a razor blade to break the outer bond around the edges of the CPU before using the vice method?

And do you still use a razor blade to break the outer bond around the edges of the CPU before using the vice method?

No, that's how people accidentally sliced off surface mounted components under the lid. The major benefit of the vice method is to avoid doing that.

I have upgraded a 4.1 with *lidded* CPUs just for fun recently, and it's all good.

No washers, but tried not to tighten 100%. Took two tries before a correct startup.

Temps are also right where they should be.

Would I recommend it? God no.

The cost of ****ing up a dual CPU board vs ****ing up 2 CPUs is very different, and most often twice the size.

While many brag about the vice method been too "violent" it's actually the safest, if carried out in a controlled environment.

No washers, but tried not to tighten 100%. Took two tries before a correct startup.

Temps are also right where they should be.

Would I recommend it? God no.

The cost of ****ing up a dual CPU board vs ****ing up 2 CPUs is very different, and most often twice the size.

While many brag about the vice method been too "violent" it's actually the safest, if carried out in a controlled environment.

Well, I took the plunge today and delidded and installed two Xeon X5680 3.33GHz CPUs into my most recently purchased cMP 4,1>5,1 2 Quad 2.26GHz. Had some issues though, all of which have been overcome:

1. I upgraded CPU A first. With CPU B removed, I reset SMC and zapped PRAM and restarted with just the upgraded CPU A. Very slow startup, but that's because it had selected my Recovery HD partition after I reset SMC and PRAM. Restarted once Recovery HD loaded. CPU must be working!!

2. After getting to the log-on screen I wasn't able to log into my User account (on my NVMe Fusion Drive), because SIP had been enabled again (due to other SMC reset and PRAM), and therefore the NVMe Kext wouldn't load.

3. Only 24GB or ram recognised (should be 32GB). Slot 1 not recognised.

4. I then shutdown, and upgraded CPU B, and restarted into my Boot drive (PCIe SSD). Both CPUs working, but only 24GB ram showing.

5. Shut down, unscrewed the heatsink screws half a turn on CPU A, and re-seated the ram. Restarted - YAY! All ram and both CPUs looking proud and strong!!

Not sure how my benchmarks relate to other people's systems, but here's my results.

Geekbench 2: 26783

Geekbench 3: 30201

Geekbench 4: 17852

1. I upgraded CPU A first. With CPU B removed, I reset SMC and zapped PRAM and restarted with just the upgraded CPU A. Very slow startup, but that's because it had selected my Recovery HD partition after I reset SMC and PRAM. Restarted once Recovery HD loaded. CPU must be working!!

2. After getting to the log-on screen I wasn't able to log into my User account (on my NVMe Fusion Drive), because SIP had been enabled again (due to other SMC reset and PRAM), and therefore the NVMe Kext wouldn't load.

3. Only 24GB or ram recognised (should be 32GB). Slot 1 not recognised.

4. I then shutdown, and upgraded CPU B, and restarted into my Boot drive (PCIe SSD). Both CPUs working, but only 24GB ram showing.

5. Shut down, unscrewed the heatsink screws half a turn on CPU A, and re-seated the ram. Restarted - YAY! All ram and both CPUs looking proud and strong!!

Not sure how my benchmarks relate to other people's systems, but here's my results.

Geekbench 2: 26783

Geekbench 3: 30201

Geekbench 4: 17852

These are my thoughts about the whole operation which I carried out about a year ago and for some reason never shared it publicly:

1 - Cutting the black silicon/adhesive was probably the most sensitive part of the project as you need to have good control. Using those double edge blades is a must in order not to scratch the PCB and not to create too much pressure between the IHS and the die.

2 - The desoldering time was not as consistent as I expected. The 3 CPUs I delidded took different times to desolder which is strange considering the iron temperature was the same (yes I used a cloth iron). The CPU that desoldered the fastest was the defective one I bought (an X5660). It only took like 7/8 seconds on the iron. The other two (X5670s) took around 15 to 20 seconds. One of them was so stubborn I took it out of the heat, waited 10 minutes and put it back for another 15 secs and that's where it popped open.

3 - Cleaning the solder on die. That was fun although I can see how that can turn ugly if you don't pay close attention to what your doing. This is another step where you can easily chop some caps off. I nearly did. When I finished scrapping the solder, I didn't like how the die looked like with all those scratches so I polished the die with some Flitz polish paste which gave them a mirror finish. Beautiful.

4 - Cleaning the remaining silicon/adhesive. This part is where I nearly ****ed everything up. Using a blade to do this is probably the cleanest way but it can very easily ruin all the hard work already done. I did scratch the sacrificial CPU while doing this although I am not sure if this could have permanently damaged the CPUs, if it was working. A plastic credit card of some other object of the sort is better suited for this task.

Some pictures for the posterity.

1 - Sacrifical X5660_Raw

2 - Sacrifical X5660_Die Cleaned_PCB chipped

3 - Original E5520 Vs Sacrifical X5660_Die side

4 - Sacrifical X5660 vs Original E5520_Die side polished

5 - Original E5520 Vs Sacrifical X5660_Grid array side

6 - Production X5670s_Raw_Cap soldered back

7 - Production X5670s_Raw vs Polished_Cap soldered back (the red circle is the cap that I decapitated and then soldered back)

8 - Production X5670_Polished_IHS_Adhesive cuttout

9 - Production X5670_Polished with reflection

1 - Cutting the black silicon/adhesive was probably the most sensitive part of the project as you need to have good control. Using those double edge blades is a must in order not to scratch the PCB and not to create too much pressure between the IHS and the die.

2 - The desoldering time was not as consistent as I expected. The 3 CPUs I delidded took different times to desolder which is strange considering the iron temperature was the same (yes I used a cloth iron). The CPU that desoldered the fastest was the defective one I bought (an X5660). It only took like 7/8 seconds on the iron. The other two (X5670s) took around 15 to 20 seconds. One of them was so stubborn I took it out of the heat, waited 10 minutes and put it back for another 15 secs and that's where it popped open.

3 - Cleaning the solder on die. That was fun although I can see how that can turn ugly if you don't pay close attention to what your doing. This is another step where you can easily chop some caps off. I nearly did. When I finished scrapping the solder, I didn't like how the die looked like with all those scratches so I polished the die with some Flitz polish paste which gave them a mirror finish. Beautiful.

4 - Cleaning the remaining silicon/adhesive. This part is where I nearly ****ed everything up. Using a blade to do this is probably the cleanest way but it can very easily ruin all the hard work already done. I did scratch the sacrificial CPU while doing this although I am not sure if this could have permanently damaged the CPUs, if it was working. A plastic credit card of some other object of the sort is better suited for this task.

Some pictures for the posterity.

1 - Sacrifical X5660_Raw

2 - Sacrifical X5660_Die Cleaned_PCB chipped

3 - Original E5520 Vs Sacrifical X5660_Die side

4 - Sacrifical X5660 vs Original E5520_Die side polished

5 - Original E5520 Vs Sacrifical X5660_Grid array side

6 - Production X5670s_Raw_Cap soldered back

7 - Production X5670s_Raw vs Polished_Cap soldered back (the red circle is the cap that I decapitated and then soldered back)

8 - Production X5670_Polished_IHS_Adhesive cuttout

9 - Production X5670_Polished with reflection

Nice work and pics.

This may be a stupid Q, but, why clean off the adhesive if it is not a 100% safe process?

This may be a stupid Q, but, why clean off the adhesive if it is not a 100% safe process?

Actually you don't need to remove it. The CPU will work just fine if you leave the adhesive. I just don't like half done jobs and I didn't want to have any residues that could potentially fall in the socket and then create problems. In fact the process is safe if done with a plastic card for example. I used the blade on the sacrificial CPU but then used a credit card on the functional CPUs and it was an easy task. The part where you really need to be patient and pay really close attention is when cutting the adhesive while the lid is still on. You can chop off some capacitors. Look how close they are from the adhesive.Nice work and pics.

This may be a stupid Q, but, why clean off the adhesive if it is not a 100% safe process?

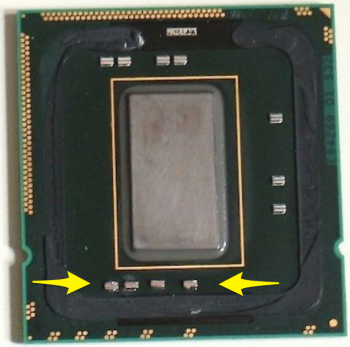

It's really hard to say because they can be damaged/broken without any 'obvious' damage. In your case I would not risk it as there are some clear visual discrepancies.Need some help folks. I'm looking at buying a pair of delidded CPUs but have concerns about one of them. Do the capacitors on this look like they might be damaged, impacting the use of the CPU or is it purely cosmetic?

Ok, my two cents...

Having just used the vice method on my practice L5520 I really don’t know why anyone would use any other method. It was unbelievably easy to do and risk free.

Oh, and cheap: https://www.amazon.co.uk/gp/aw/d/B0002JT6AE/

The solder on the chip, as well as the black glue on the sides, can then be scraped away with a credit card and fingernail.

Very, very easy. If you have a dual CPU 2009 cMP you really should not be put off by having to delid

Having just used the vice method on my practice L5520 I really don’t know why anyone would use any other method. It was unbelievably easy to do and risk free.

Oh, and cheap: https://www.amazon.co.uk/gp/aw/d/B0002JT6AE/

The solder on the chip, as well as the black glue on the sides, can then be scraped away with a credit card and fingernail.

Very, very easy. If you have a dual CPU 2009 cMP you really should not be put off by having to delid

Last edited:

As an Amazon Associate, MacRumors earns a commission from qualifying purchases made through links in this post.

Hi,

I've updated my 4.1 Mac Pro last year with a pair of X5680.

I've installed those 2CPUs without removing the ISH. Works perfectly since then along a Nvidia 980ti.

A great machine which gives me 100% satisfaction with 0KP beside when it comes to update the Nvidia driver.

I've updated my 4.1 Mac Pro last year with a pair of X5680.

I've installed those 2CPUs without removing the ISH. Works perfectly since then along a Nvidia 980ti.

A great machine which gives me 100% satisfaction with 0KP beside when it comes to update the Nvidia driver.

So the key here is: research, practise and then do – this will almost guarantee 100% success regardless of which method you use.

Register on MacRumors! This sidebar will go away, and you'll see fewer ads.